Abstract

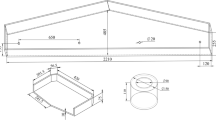

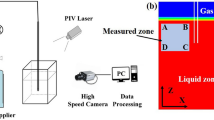

Water modeling, using microbubble swarms, was performed in a full-scale, four-strand, delta-shaped tundish, located at the McGill Metals Processing Centre (MMPC). The objective of the study was to investigate the effectiveness of microbubbles in removing inclusions smaller than 50 μm, applying the principles and conditions previously researched using a smaller scale arrangement. Air was injected into a full-scale model of a ladle shroud (the connecting tube through which liquid steel flows into the tundish below). The model ladle shroud was fitted with twelve, laser-drilled orifices, so as to create microbubbles. The bubbles generated using different gas injection protocols were recorded using a high-speed camera, and the bubble images were postprocessed using the commercial software, ImageJ. With this newly designed ladle shroud, bubble sizes could be reduced dramatically, to as small as a 675 µm average diameter. A three-dimensional, CFD model simulation was developed, using parameters obtained from the corresponding water model experiments, in order to predict the behavior of these microbubbles within the tundish and their potential influence on flow patterns and inclusion float-out capability.

Similar content being viewed by others

Abbreviations

- C D :

-

Drag coefficient (−)

- d b :

-

Diameter of bubble (m)

- Fr:

-

Froude number (−)

- g :

-

Gravity acceleration (m2/s)

- G k :

-

Generation rate of turbulence kinetic energy (−)

- H :

-

Height of liquid bath

- I :

-

Turbulence intensity (−)

- k :

-

Turbulent kinetic energy (m2/s2)

- l :

-

Turbulence length scale (m)

- L :

-

Characteristic length (m)

- L e :

-

Eddy length scale (m)

- l 0 :

-

Length scale associated with small vortices (m)

- \( \dot{m}_{\text{b}} \) :

-

Mass flow rate of bubbles (kg/s)

- n i :

-

Number density of inclusions (number/m3)

- N i :

-

Number of inclusions removed per unit time (number/s)

- N b :

-

Number of bubbles (−)

- p :

-

Pressure (Pa)

- P, P C, P A :

-

Attachment, collision, and adhesion probability between inclusion and bubbles (−)

- Q g :

-

Gas flow rate (m3/s)

- R orifice :

-

The radius of the gas injection port (m)

- Re:

-

Reynolds number (−)

- Stk:

-

Stokes number (−)

- t cross :

-

Eddy crossing time (s)

- t r :

-

Bubble residence time (s)

- Δt :

-

Time step (s)

- u, u b :

-

Velocity of fluid flow and bubbles (m/s)

- u av, u′:

-

Average fluid velocity and the fluctuation of the velocity (m/s)

- u air :

-

Velocity of the gas crossing the orifice (m/s)

- V s :

-

Swept volume (m3)

- Wec :

-

Critical Weber number (−)

- ρ, ρ g :

-

Densities of liquid and gas (kg/m3)

- ε :

-

Turbulent dissipation rate (m2/s3)

- ζ :

-

Normally distributed random number (−)

- μ eff, μ, μ t :

-

Effective viscosity, laminar viscosity, and turbulent viscosity (kg/(m s))

- σ :

-

Surface tension (N/m)

- τ e, τ p :

-

Eddy life time and relaxation time (s)

- DLS:

-

Dissipative ladle shroud

- DPM:

-

Discrete phase model

- RTD:

-

Residence time distribution

- SEN:

-

Submerged entry nozzle

References

Y. Miki, B. G. Thomas Metall. Mater. Trans. B, 1999, vol. 30B, pp. 639-654.

Y. Sahai and T. Emi: ISIJ Int., 1996, vol. 36, pp. 667-672.

C. Chen, L. T. I. Jonsson, A. Tilliander, G. G. Cheng, P. G. Jonsson: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 169-190.

D. Mazumdar and R. I. L. Guthrie: ISIJ Int., 1999, vol. 39, pp. 524-547.

P. K. Jha, P. S. Rao and A. Dewan: ISIJ Int., 2008, vol. 48, pp. 154-160.

R. D. Morales, J. D. J. Barreto, S. Lopez-Ramirez, J. Palafox-Ramos and D. Zacharias: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1505-1515.

A. Cwudzinski: Steel Res. Int., 2014, vol. 85, pp. 902-917.

K. Morales-Higa, R. I. L. Guthrie and M. Isac: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 63-79.

S. Lopez-Ramirez, J. D. J. Barreto, Palafox-Ramos, R. D. Morales and D. Zacharias: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 615-627.

L. F. Zhang, J. Aoki and B. G. Thomas: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 361-379.

H. L. Yang, P. He and Y. C. Zhai: ISIJ Int., 2014, vol. 54, pp. 578-581.

A. Vargas-Zamora, R. D. Morales, M. Diaz-Cruz, J. Palafox-Ramos, J. D. J. Barreto-Sandoval: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 247-257.

J. Wang, M. Y. Zhu, H. B. Zhou, Y. Wang: J. Iron Steel Res. Int., 2008, vol. 15(4), pp. 26-31.

A. Cwudzinski: Steel Res. Int., 2010, vol. 81, pp. 123-131.

J. P. Rogler, L. J. Heaslip and M. Mehrvar: Can. Metall. Q., 2003, vol. 43, pp. 407-415.

A. Ramos-Banderas, R. D. Morales, L. Garcia-Demedices and M. Diaz-cruz: ISIJ Int., 2003, vol. 43, pp. 653-662.

S. Chang, L. C. Zhong and Z. S. Zou: ISIJ Int., 2015, vol. 55, pp. 837-844.

L. F. Zhang and S. Taniguchi: Int. Mater. Rev., 2000, vol. 45, pp. 59-82.

K. Chattopadhyay, M. Isac and R. I. L. Guthrie: ISIJ Int., 2011, vol. 51, pp. 573-580.

X.Y. Ren, Master Thesis, McGill University, Montreal, QC, Canada, 2014.

R.I.L. Guthrie and M. Isac: ISSTech Conf. 2003, AIST, Indianapolis, IN, 2003, pp. 1201–11

W. P. Jones and B. E. Launder: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 301-314.

B. E. Launder and D. B. Spalding: Comput. Methods Appl. Mech. Eng., 1974, vol. 3, pp. 269-289.

S. A. Morsi and A. J. Alexander: J. Fluid. Mech., 1972, vol. 55, pp. 193-208.

FLUENT 14.5 Theory Guide, Section 16.2.2.

G. S. Dobby and J. A. Finch: Int. J. Miner. Process., 1987, vol. 21, pp. 241-260.

A. V. Nguyen, H. J. Schulze, and J. Ralston: Int. J. Miner. Process., 1997, vol. 51, pp. 183-195.

A. V. Nguyen: J. Colloid Interface Sci., 1994, vol. 162, pp. 123-138.

M. E. Weber and D. Paddock: J. Colloid Interface Sci., 1983, vol. 94, pp. 328-335.

S.H. Marshall, M.W. Chudacek, and D.F. Bagster: Chem. Eng. Sci., 1993, vol. 48, pp. 2049-2059.

J. O. Hinze: AIChE J., 1955, vol. 1, pp. 289-295

G. M. Evans, G. J. Jameson and B. W. Atkinson: Chem. Eng. Sci., 1992, vol. 47, pp. 3265-3272.

Acknowledgments

The authors are indebted to NSERC, and to RTIT for research funding, to the MMPC for giving access to all its research facilities, and to ANSYS Inc. for providing the license of Fluent. The first author is also grateful to the China Scholarship Council for the financial support during his Ph. D studies at McGill.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 27, 2015.

Rights and permissions

About this article

Cite this article

Chang, S., Cao, X., Zou, Z. et al. Microbubble Swarms in a Full-Scale Water Model Tundish. Metall Mater Trans B 47, 2732–2743 (2016). https://doi.org/10.1007/s11663-016-0747-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0747-1