Abstract

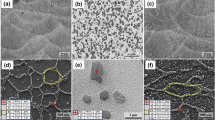

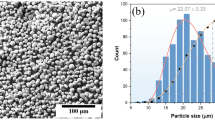

A good combination of strength and fracture toughness is required for aerospace applications of laser additively manufactured (LAM) AerMet100 steel. To understand the role of microstructure in the combination of strength and fracture toughness of LAM AerMet100 steel, microstructures, fracture toughness properties and corresponding crack-tip fracture behaviors of the as-deposited specimen and five types of heat-treated specimens were mainly investigated. The results indicate the as-deposited microstructure of LAM AerMet100 steel with a high amount of retained austenite has a high KIC value of ~ 81.7 MPa m1/2. After a short process of cryogenic treatment and subsequent tempering treatment, the KIC value of the steel has the lowest value of ~ 60 MPa m1/2 due to the apparent decrease of austenite and weak cracking resistance, associating with intergranular cracking along the prior austenite columnar grain boundaries and transgranular cracking of intercellular regions. In contrast, the crack-tip fracture mode of the equiaxed-grain tempered martensite microstructure of LAM AerMet100 steel becomes completely transgranular cracking with the main mechanisms of micro-void nucleation and coalescence. Homogenization treatment can apparently decrease the amount and size of large-size alloy carbides and effectively improve the fracture toughness of the steel. Furthermore, proper microstructure modification (including control of large-size carbide, grain refinement and a decrease of retained austenite) by a longer treatment process can prompt tempered LAM AerMet100 steel to achieve a good combination of yield strength (~ 1827 MPa) and fracture toughness (~ 113 MPa m1/2) compared with the wrought one.

Similar content being viewed by others

References

[1] Y. Gan, Z.L. Tian, H. Dong, D. Feng, X.L. Wang: China Materials Engineering Canon, vol. 3B, Chemical Industry Press, Beijing, 2005, pp. 1038-1054.

[2] R. Ayer, P.M. Machmeier: Metal.Trans. A, 1993, vol. 24, pp. 1943-55.

[3] A. Oehlert, A. Atrens: J. Mater. Sci., 1998, vol. 33, pp. 775-81.

[4] X.L. Zheng: Mechanical behavior of engineering materials, Northerwestern Polytechnical University Press, Xian, 2004, pp. 64-102.

A. International, Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials, ASTM International, West Conshohocken, PA, 2020.

N.E. Dowling: Mechanical Behavior of Materials. PEARSON, New York. 2013, pp. 334-402.

[7] P. Chowdhury, H. Sehitoglu: Fatigue Fract. Eng. M., 2016, vol. 39, pp.652-74.

[8] X. Shi, W. Zeng, Q. Zhao, W. Peng, C. Kang: J. Alloys Comp., 2016, vol. 679, pp. 184-190.

[9] C. Wang, C. Zhang, Z. Yang, J. Su, Y. Weng: Mat. Sci. Eng., 2015, vol. 646, pp: 1-7.

[10] T. Wang, Y.Y. Zhu, S.Q. Zhang, H.B. Tang, H.M. Wang, J. Alloys Comp., 2015, vol. 632, pp. 505-13.

[11] H. Cheng, D. Liu, H. Tang, S. Zhang, X. Ran, H. Wang: J. Iron Steel Res. Int., 2013, vol. 20, pp. 79-84.

[12] X. Ran, D. Liu, A. Li, H. Wang, H. Tang, X. Cheng: Mat. Sci. Eng. A, 2016, vol. 663, pp. 69-77.

[13] X.-z. Ran, D. Liu, J. Li, X. Liu, H.-m. Wang, X. Cheng, B. He, H.-b. Tang: Mat. Sci. Eng. A, 2018, vol. 723, pp. 8-21.

[14] X.-z. Ran, D. Liu, J. Li, H.-m. Wang, X. Cheng, J.-k. Zhang, H.-b. Tang, X. Liu: Mat. Sci. Eng. A, 2018, vol. 721, pp. 251-262.

[15] H. Duan, X. Liu, X. Ran, J. Li, D. Liu: Mat. Sci. Eng. A, 2017, vol. 704, pp. 32-7.

[16] R.S. Thomas, D. Li, R. Gangloff, J. Scully: Metall. Mater. Trans. A, 2002, vol. 33, pp. 1991-2004.

[17] C.R. Cheng: Fatigue and fracture, Huazhong University of Science & Technology Press, Wuhan, 2002, pp. 95-109.

[18] C.N. Sastry, K.H. Khan, W.E. Wood: Metal.Trans. A, 1982, vol. 13, pp. 676-80.

[19] J.W. Bray, K.J. Handerhan, W.M. Garrison, A.W. Thompson: Metal.Trans. A, 1992, vol. 23, pp. 485-496.

[20] R.O. Ritchie, B. Francis, W.L. Server: Metal.Trans. A, 1976, vol. 7, pp. 831-8

[21] R.O. Ritchie, R.M. Horn: Metal.Trans. A, 1978, vol. 9, pp. 331-41.

[22] K.J. Handerhan, W.M. Garrison: Metal.Trans. A, 1988, vol. 19, pp. 2989-3003.

W. Zhou, K. Tsunoda, N. Nomura, K. Yoshimi: Mater. Design, 2020, vol. 196, 109132.

[24] K.K. Sankaran, R.S. Mishra: Chapter 6 - Ultrahigh Strength Steels, Metallurgy and Design of Alloys with Hierarchical Microstructures, Elsevier2017, pp. 289-343.

C.T. Corporation: Superior Aerospace Alloys Engineered for the Commercial and Defense Aircraft of Tomorrow, 2018, https://www.carpentertechnology.com/en/markets/aerospace.

Acknowledgments

This work was supported by the National Key Research and Development Program of China (grant no. 2018YFB1105800) and Youth Program of the National Natural Science Foundation of China (grant no. 51901010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 24, 2020; accepted December 31, 2020.

Rights and permissions

About this article

Cite this article

Ran, Xz., Zhang, Sq., Liu, D. et al. Role of Microstructural Characteristics in Combination of Strength and Fracture Toughness of Laser Additively Manufactured Ultrahigh-Strength AerMet100 Steel. Metall Mater Trans A 52, 1248–1259 (2021). https://doi.org/10.1007/s11661-021-06148-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06148-1