Abstract

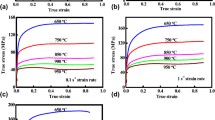

The Cu-Cr-Zr-Ti alloy was subjected to single-hit plane strain compression tests in the temperature range of 923 K to 1073 K (650 °C to 800 °C) and at two different strain rates of 0.1 and 1 s−1. These tests were performed to ascertain the kinetics of microstructural evolution resulting by dynamic recrystallization (DRX) in the alloy under hot deformation conditions. The differences in the extent of DRX under various deformation conditions were established by plotting fractional softening as a function of strain and time. Further, the Avrami exponent was found to decrease with increase in deformation temperature. This was attributed to early onset of recrystallization leading to subsequent work hardening of the recrystallized grains and grain growth at higher temperatures which results in the loss of nucleation sites due to reduced grain boundary area. Microstructural observations made using optical microscopy, scanning electron microscopy (SEM), and electron backscattered diffraction (EBSD) revealed nucleation to occur in the following steps: elongation of grains perpendicular to the compression direction, bulging of elongated grain boundaries due to strain-induced boundary migration (SIBM), and subsequent subgrain formation behind the bulged boundary due to strain-induced low-angle boundaries. Finally, the equation describing the DRX kinetics under plane strain conditions for the alloy was established as \( X = 1 - \exp \left[ { - 0.455 \times \left( {{{\left( {\varepsilon - \varepsilon_{\text{c}} } \right)} \mathord{\left/ {\vphantom {{\left( {\varepsilon - \varepsilon_{\text{c}} } \right)} {\varepsilon_{\text{p}} }}} \right. \kern-0pt} {\varepsilon_{\text{p}} }}} \right)^{2.84} } \right] \).

Similar content being viewed by others

References

C.M. Sellars, W.J. McG. Tegart, International Metallurgical Reviews 1972, vol. 17, pp. 1-24.

J. Jonas, C. M. Sellars, W. J. McG. Tegart, Metallurgical Reviews, 1969, vol. 14, pp. 1-24.

H.J. McQueen, N.D. Ryan, Materials Science and Engineering A, 2002, vol. 322, pp. 43-63.

H. Mirzadeh, Mechanics of Materials, 2015, vol. 85, pp. 66–79.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metallurgical Transactions A, 1984, vol. 15, pp. 1883-1892.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Progress in Materials Science, 2014, vol. 60, pp. 130–207.

K. Huang, R.E. Logé, Materials and Design, 2016, vol. 111, pp. 548–574

Y. Zhang, H. Sun, A. A. Volinsky, B. Tian, Z. Chai, P. Liu, Acta Metallurgica Sinica 2016, vol. 29, pp. 422–430.

Y. Zhang, Z. Chai, A. A. Volinsky, B. Tian, H. Sun, P. Liu, Y. Liu, Materials Science & Engineering A, 2016, vol. 662, pp. 320–329.

Y. Zhang, Z. Chai, A. A. Volinsky, H. Sun, B. Tian, P. Liu, Y. Liu, Journal of Materials Engineering and Performance, 2016, vol. 25, pp. 1191-1198.

H. Zhang, J. Wang, Q. Chen, D. Shu, C. Wang, G. Chen, Z. Zhao, Journal of Alloys and Compounds, 2019, vol. 784, pp. 1071-1083

I. S. Batra, G. K. Dey, U. D. Kulkarni, S. Banerjee, Journal of Nuclear Materials, 2001, vol. 299, pp. 91-100.

I. S. Batra, G. K. Dey, U. D. Kulkarni, S. Banerjee, Materials Science & Engineering A, 2002, vol. 356, pp. 32-36.

G. Sudarshan-Rao, V. M. J. Sharma, S.G. Sundara-Raman, M. Amruth, P. Ramesh-Narayanan, S. C. Sharma, P.V. Venkitakrishnan, Materials Science & Engineering A, 2016, vol. 668, pp. 97–104.

G. Sudarshan-Rao, J. Srinath, S. G. Sundara-Raman, V.M.J. Sharma, S.V.S. Narayana-Murty, P. Ramesh-Narayanan, K. Thomas-Tharian, P. Ram-Kumar, P.V. Venkitakrishnan, Materials Science & Engineering A, 2017, vol. 692 pp. 156–167.

S. Chenna-Krishna, G. Sudarsana-Rao, A. K. Jha, B Pant, P.V. Venkitakrishnan, Materials Science & Engineering A 674 (2016) 164–170.

P. Zhang, J. Jie, Y. Gao, T. Wang, T. Li, Materials Science Forum, 2015, vol. 817, pp. 307-311.

A. Sarkar, S.V.S. Narayana-Murty, M.J.N.V. Prasad, Materials Performance and Characterization, 2019, vol. 8, pp. 1076–1090.

A. Sarkar, M.J.N.V. Prasad, S.V.S. Narayana-Murty, Materials Characterization, 2020, vol. 160, 110-112.

S.V.S. Narayana-Murty, B. Nageswara-Rao, B.P. Kashyap, International Materials Reviews, 2000, vol. 45, pp. 15-26.

S.V.S. Narayana-Murty, A. Sarkar, P. Ramesh-Narayanan, P.V. Venkitakrishnan, J. Mukhopadhyay, Materials Science & Engineering A, 2016, vol. 677, pp. 41–49.

E. I. Poliak, J. J. Jonas, Acta Materialia, 1996, vol. 44, pp. 127- 136.

H. Mirzadeh, A. Najafizadeh, Materials and Design, 2010, vol. 31, pp.1174–1179.

S. Solhjoo, Materials and Design, 2009, vol. 30, pp. 3036–3040.

T. Sakai, J. J. Jonas, Acta Metallurgica, 1984, vol. 32, pp. 189-209.

D. Qian, Y. Peng, Journal of Materials Engineering and Performance, 2015, vol. 24, pp. 1906-1917.

J. J. Jonas, X. Quelennec, L. Jiang, E. Martin, Acta Materialia, 2009, vol. 57, pp. 2748–2756.

M. El Wahabi, L. Gavard, F. Montheillet, J.M. Cabrera, J.M. Prado, Acta Materialia, 2005 vol. 53, pp. 4605–4612.

A.M. Wusatowska-Sarnek, H. Miura, T. Sakai, Materials Science & Engineering A, 2002, vol. 323, pp. 177–186.

B. Verlinden, J. Driver, I. Samajdar, R. D. Doherty, R. W. Cahn (Editor), Thermo-mechanical processing of metallic materials, Pergamon Mater. Ser., 2007, pp. 168–77.

S. Suwas, R.K. Ray, B. Derby (Series Editor), Crystallographic Texture of Materials, Springer Engineering Materials and Processes Series, 2014, pp. 109–113.

F.J. Humphreys, M. Hatherly, Recrystallization and related annealing phenomena, 2nd edition, 2014, Elsevier, Amsterdam, pp. 68-72.

Acknowledgement

The authors wish to acknowledge the Indian Space Research Organization for their funding support provided under the Project Number RD/0116-ISRO000-006. The authors are grateful to the Centre of Excellence in Steel Technology (CoEST) and National OIM-Texture lab of IIT Bombay for extending Gleeble 3800-GTC and EBSD facilities for carrying out the plane strain compression tests and EBSD analysis, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manucsript submitted March 16, 2020.

Rights and permissions

About this article

Cite this article

Sarkar, A., Murty, S.V.S.N. & Prasad, M.J.N.V. Dynamic Recrystallization in Cu-Cr-Zr-Ti Alloy Under Large Plane Strain Conditions. Metall Mater Trans A 51, 4742–4752 (2020). https://doi.org/10.1007/s11661-020-05892-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05892-0