Abstract

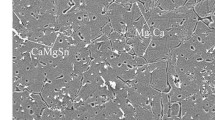

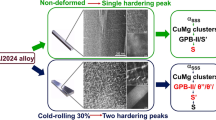

This study addresses specific features of microstructural development during the rolling of the as-cast magnesium-rich aluminum alloys with added transition metal elements, such as Zr and Sc. For investigation purposes, three magnesium-rich aluminum alloys were chosen: 5182 without added Zr and Sc, 1565 ch with added Zr and 1570 with added Zr and Sc. Optical microscopy, X-ray texture analysis, electron microscopy, and electron backscattered diffraction methods were used in this study. This study demonstrates that two completely different patterns can be observed in the microstructure during deformation. Two zones with different subgrain sizes are formed when the alloy tends to recrystallize. Without recrystallization, the structure develops homogeneously. Recrystallization also has a significant effect on the texture formation. If recrystallization does not occur, a strong β-fiber texture is formed. However, this type of texture tends not to form during inter-deformation intervals when recrystallization occurs. Second-phase particles have the strongest effect on microstructural evolution during the hot deformation of the as-cast structure. Fine particles are capable of inhibiting recrystallization. Coarse particles initiate the PSN (particle-stimulated nucleation) mechanism and suppress the growth of the cubic texture component during recrystallization. An adequate combination of coarse and fine particles enables either better homogeneity of the structure distribution in the deformation center or better grain structure refinement.

Similar content being viewed by others

References

V. V. Zakharov: Met. Sci. Heat Treat., 2017, vol. 59, pp. 67–71.

J. Hirsch: Mater. Trans., 2011, vol. 52, pp. 818–24.

M. A. Wells, I. V. Samarasekera, J. K. Brimacombe, E. B. Hawbolt, and D. J. Lloyd: Metall. Mater. Trans. B., 1998, vol. 29, pp. 611–20.

E. V. Aryshenskii, V. Y. Aryshenskii, A. F. Grechnikova, and E. D. Beglov: Met. Sci. Heat Treat., 2014, vol. 56, pp. 347–52.

J. Hirsch: Fundamentals of Aluminium Metallurgy. Woodhead Publishing, Sawston, 2011, pp. 719–46.

M. A. Wells, I. V. Samarasekera, J. K. Brimacombe, E. B. Hawbolt, and D. J. Lloyd: Metall. Mater. Trans. B., 1998, vol. 29, pp. 709–19.

H. E. Vatne, T. Furu, R. Ørsund, and E. Nes: Acta Mater., 1996, vol. 44, pp. 4463–73.

O. Engler and H. E. Vatne: JOM, 1998, vol. 50, pp. 23–27.

C. Schäfer, V. Mohles, and G. Gottstein: Applications of Texture Analysis. Wiley, New York 2008, pp. 537–45

O. Dalland and E. Nes: Acta Mater., 1996, vol. 44, pp. 1389–411.

O. Engler: Mater. Sci. Forum., 2007, vol. 550, pp. 23–34.

E. Povoden-Karadeniz, P. Lang, K. I. Öksüz, W. Jun, S. Rafiezadeh, A. Falahati, E. Kozeschnik: Mater. Sci. Forum., 2013, vol. 765, pp. 476-80

P. Lang, T. Weisz, M. R. Ahmadi, E. Povoden-Karadeniz, A. Falahati, & E. Kozeschnik: Adv. Mater. Res., 2014, vol. 922, pp. 406-411

M. Piotr, R. Bureau, C. Poletti, C. Sommitsch, P. Warczok, and E. Kozeschnik. Key Eng. Mater., 2015, vol. 651-653. pp. 1319-24

F. J. Humphreys and M. Hatherly: Recrystallization and related annealing phenomena, Elsevier, New York, 2012

A. V. Andrianov, E. G. Kandalova, E. V. Aryshensky, and A. F. Grechnikova: Key Eng. Mater., 2016, vol. 684. pp. 398-405

Sukhopar, Olga, and Günter Gottstein: Mater. Sci. Forum., 2012, vol. 715, pp. 455–60.

O. Engler: Mater. Sci. Forum., 2003, vol. 426-432, pp. 3655–60.

C. Schäfer, G. Pomana, V. Mohles, G. Gottstein, O. Engler, and J. Hirsch: Adv. Eng. Mater., 2010, vol. 12, pp. 131–40.

J. Hirsch: Mater. Sci. Forum., 2005, vol. 495, pp. 1565–72.

O. Engler, L. Löchte, and J. Hirsch: Acta Mater., 2007, vol. 55, pp. 5449–63.

M. Crumbach, M. Goerdeler, and G. Gottstein: Acta Mater., 2006, vol. 54, pp. 3275–89.

Gottstein, G., and V. Mohles.: In Proceedings of the 1st World Congress on Integrated Computational Materials Engineering (ICME), 2011, p. 9.

J. Hjelen, R. Ørsund, and E. Nes: Acta Metall. Mater., 1991, vol. 39, pp. 1377–404.

V. G. Davydov, V. I. Elagin, V. V. Zakharov, and D. Rostoval: Met. Sci. Heat Treat., 1996, vol. 38, pp. 347–52.

M. S. Kaiser, S. Datta, A. Roychowdhury, and M. K. Banerjee: Mater. Manuf. Processes., 2007, vol. 23, pp. 74–81.

A. Patra, S. Ganguly, P. P. Chattopadhyay, and S. Datta: Multidiscip. Model. Mater. Struct., 2015, vol. 11, pp. 401–12.

A. W. Yu, C. G. Yang, S. L. Wang, F. C. Liu, and Q. Zheng: Appl. Mech. Mater., 2014, vol. 508, pp. 16–21.

F. Wang, D. Qiu, Z. L. Liu, J. A. Taylor, M. A. Easton, and M.X. Zhang: Acta Mater., 2013, vol. 61, pp. 5636–45.

H.-y. Li, D.-w. Li, Z.-x. Zhu, B.-a. Chen, X. Chen, C.-l. Yang, H.-y. Zhang, and W. Kang: Trans. Nonferrous Met. Soc. China, 2016, vol. 26, pp. 3059–69.

F. Wang, D. Qiu, Z.-l. Liu, J. Taylor, M. Easton, and M.-X. Zhang: Trans. Nonferr. Met. Soc. China, 2014, vol. 24, pp. 2034–40.

F. Wang, Z. Liu, D. Qiu, J. A. Taylor, M. A. Easton, and M.-X. Zhang: Acta Mater., 2013, vol. 61, pp. 360–70.

E. Nes, N. Ryum, and O. Hunderi: Acta Metall., 1985, vol. 33, pp. 11–22.

O. Engler, Z. Liu, and K. Kuhnke: J. Alloys Compd. 2013, vol. 560, pp. 111–22.

O. Engler and S. Miller-Jupp: J. Alloys Compd. 2016, vol. 689, pp. 998–1010.

H. Zhang, D. S. Peng, L. B. Yang, and L. P. Meng: Trans. Nonferrous Met. Soc. China., 2001, vol. 11. pp. 13-17.

B. Forbord, H. Hallem, N. Ryum, and K. Marthinsen: Mat. Sci. Eng. A., 2004, vol. 387-389, pp. 936–39.

J. Røyset, N. Ryum: Int. Mater. Rev. 2005. vol. 50, pp. 19–44

Aryshenskii, E., Hirsch, J., Yashin, V., Sergei, K., & Kawalla, R. (2018). J. Mater. Eng. Perform., vol. 27, 6780-99.

K. Sjølstad.: Deformation and softening behaviour of commercial AlMn-alloys: Experiments and modelling. PhD thesis, Norwegian, 2003.

H. E. Vatne and M. A. Wells: Can. Metall. Q. 2003, vol. 42, pp. 79–88.

O. Engler, C. N. Tomé, and M.-Y. Huh: Metall. Mater. Trans. A, 2000, vol. 31, pp. 2299–315.

W. B. Hutchinson: Acta Metall.,, 1989, vol. 37, pp. 1047–56.

O. Engler: Acta Mater., 1998, vol. 46, pp. 1555–68.

Y. Filatov, V. Yelagin, and V. Zakharov: Mat. Sci. Eng. A., 2000, vol. 280, pp. 97–101.

Engler, O., Hirsch, J., & Lücke, K. Acta Metall., 1989, vol. 37, pp. 2743–53.

J. Hirsch, K. Lücke: Overview No. 76: Acta Metall., 1988, vol. 36. pp. 2863-82.

Hansen N., Jensen D. J. Metall. Mater. Trans. A., 1986, vol. 17. pp. 253-59.

Randle, Valerie, and Olaf Engler. Introduction to texture analysis: macrotexture, microtexture and orientation mapping. CRC Press, Boca Raton, 2014.

J. Hirsch: Mater. Sci. Forum., 2003, vol. 426-432, pp. 185–94.

M. Cabibbo, S. Spigarelli, and E. Evangelista: Metall. Mater. Trans. A, 2004, vol. 35, pp. 293–300.

B. I. Elagin, V. V. Zakharov, and T. D. Rostova: Met. Sci. Heat Treat., 1993, vol. 35. pp 317–319

R. W. Hyland: Metall Mater Trans A, 1992, vol. 23., pp. 1947-1955

A. Norman, P. Prangnell, and R. McEwen: Acta Mater., 1998, vol. 46, pp. 5715–32.

Vatne, H. E., Ørsund, R., Marthinsen, K., & Nes, E. Metall. Mater. Trans. A, 1996, vol 27, pp. 4133-44.

Aryshenskii, E., Kawalla, R., & Hirsch, J. Steel Res. Int, 2017, vol. 88, pp. 1700053.

Acknowledgment

This study is funded by a grant provided by the Russian Science Foundation, Project 18-79-10099.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 9, 2019.

Rights and permissions

About this article

Cite this article

Aryshenskii, E.V., Hirsch, J., Konovalov, S.V. et al. Specific Features of Microstructural Evolution During Hot Rolling of the As-Cast Magnesium-Rich Aluminum Alloys with Added Transition Metal Elements. Metall Mater Trans A 50, 5782–5799 (2019). https://doi.org/10.1007/s11661-019-05480-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05480-x