Abstract

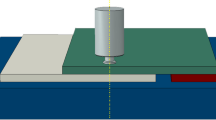

Friction stir lap joining of 6061-T6 and zinc-coated steel was performed using a high rotation speed and small tools with different pin lengths. During the welding process, the average axial force ranged from 0.2 to 1.1 kN, which is smaller than that for conventional friction stir welding. Satisfactory surface formation was achieved using a pinless tool and smaller plunge depth. The highest failure load of 2.26 kN was achieved for a pin length of 0.3 mm, plunge depth of 0.3 mm, and welding speed of 50 mm/min. The specimen fractured at the advance side of the 6061-T6 base metal. A continuous and compact interface layer with a thickness of 5.2 μm was formed. The main component of the intermetallic compound at the interface was Fe4Al13. The intermetallic compound was tightly connected and bound to the steel galvanized sheet and aluminum side.

Similar content being viewed by others

References

G. Kobe: Chilton’s Autom. Industries, 1994, vol. 174, pp. 44.

S. Ramasamy: Weld. J., 2000, vol. 79, pp. 35–39.

H. M. Liang, K. Yan, Q.Z. Wang and Y. Zhao: Journal of Materials Engineering and Performance, 2016, vol. 25, pp. 5486–93.

A. Bagheri, T. Azdast and A. Doniavi: Materials and Design, 2013, vol.43, pp. 402–409.

X. Cao and M. Jahazi: Materials and Design, 2011, vol.32, pp. 1-11.

D. H. Choi, B. W. Ahn, C. Y. Lee, Y. M. Yeon, K. Song and S. B. Jung: Intermetallics, 2011, vol. 19, pp. 125-130.

R. S. Mishra and Z. Y. Ma: Materials Science and Engineering, 2005, vol.50, pp.1-78.

K. E. Knipström and B. Pekkari: Welding Journal, 1997, vol. 9, pp. 55-59.

A. Elrefaey, M. Gouda, M. Takahashi and K. Ikeuchi: Journal of Materials Engineering and Performance, 2005, vol. 14, pp. 10-17.

H. Das, S. Basak, G. Das, T. K. Pal: Advanced Materials Research, 2012,vol. 628, pp. 7.

K. Kimapong and T. Watanabe: Materials Transactions, 2005, vol. 46, pp. 835-841.

K. Kimapong and T.Watanabe: Materials Transactions, 2005, vol. 46, pp. 2211-17.

Y. C. Chen and K. Nakata: Metallurgical and Materials Transactions A, 2008, vol. 39, pp. 1985-92.

Y. C. Chen, T. Komazaki, T. Tsumura and K. Nakata: Materials Science and Technology, 2008, vol.24, pp. 33-39.

Y. C. Chen, T. Komazaki, Y. G. Kim, T. Tsumura, K. Nakata: Materials Chemistry and Physics, 2008, vol. 111, pp. 375-380.

G. Zhang, W. Su, J. Zhang and Z. Wei: Metallurgical & Materials Transactions A, 2011, vol.42, pp. 2850-61.

K. Kumar, S. V. Kailas: Materials and Design, 2007, vol. 29, pp. 791-797.

S. Chen, Y. Zhou, J. Xue, R. Ni, Y. Guo and J. Dong: Journal of Materials Engineering and Performance, 2017, vol. 26, pp. 1-9.

Joaquin M. Piccini, Hernan G. Svoboda: Procedia Materials Science, 2015, vol. 9, pp. 504-513.

A. Yazdipour, A. Heidarzadeh: Int. J. Adv. Manuf. Technol. 2016, 87(9–12), pp. 1-8.

G. L. Qin, Y. H. Su, S. J. Wang: Transactions of Nonferrous Metals Society of China, 2014,vol. 24(4), pp. 989-995.

A. Naumov, C. Mertin, F. Korte, G. Hirt, and U. Reisgen: Production Engineering, 2017, vol. 11(2), pp. 175-182.

Acknowledgments

This research was sponsored by the Qing Lan Project, the National Post-Doctoral Fund (2017M611749), the National Natural Science Foundation of China (51675248), the Natural Science Fund of the Jiangsu Higher Education Institutions of China (17KJA460006), and the Natural Science Foundation of Jiangsu (BK20171308). The authors would also like to thank Tiffany Jain, M.S., from Liwen Bianji, Edanz Group China (www.liwenbianji.cn/ac), for editing the English text of an earlier draft of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 22, 2018.

Rights and permissions

About this article

Cite this article

Chen, S., Zhang, J., Wang, D. et al. Study on Low Axial Load Friction Stir Lap Joining of 6061-T6 and Zinc-Coated Steel. Metall Mater Trans A 50, 4642–4651 (2019). https://doi.org/10.1007/s11661-019-05369-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05369-9