Abstract

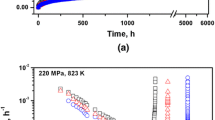

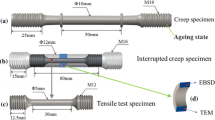

In this study, to refine the microstructure and enhance the mechanical properties, thermomechanical treatment (TMT) was performed on modified 9Cr-1Mo steel. The creep deformation behavior of TMT processed steel and the steel in its normalized and tempered (NT) state were studied for different stress levels at 923 K (650 °C). Transient, secondary, and tertiary creep regimes were analyzed for both conditions of the steel based on the empirical equation \( \varepsilon = \varepsilon_{0} + \varepsilon_{\text{t}} \left( {1 - e^{ - rt} } \right) + \varepsilon_{\text{s}}^{ \cdot } t + \varepsilon_{\text{L}} e^{{p\left( {t_{\text{t}} - t_{\text{r}} } \right)}} \). The rate of exhaustion of primary creep (r), r with time to reach the minimum creep rate, minimum creep rate\( \left( {\varepsilon_{ \hbox{min} }^{ \cdot } } \right) \), \( \varepsilon_{ \hbox{min} }^{ \cdot } \) with time spent in the secondary creep regime, rate of acceleration of tertiary creep (p), p with time to reach the onset of tertiary creep, and creep rate with applied stress exhibited a proportional relationship in both conditions of the steel. This proportionality existence in the transient and tertiary creep deformation obeyed the first-order reaction rate kinetic theory. The enhanced MX (M = V, Nb; X = C, N) precipitation in the TMT steel significantly decreased the creep deformation rate and extended the secondary stages of deformation. TMT processing of modified 9Cr-1Mo steel led to a significant increase in the creep rupture strength through the stable microstructure.

Similar content being viewed by others

References

K. Maruyama, K. Sawada, and J. Koike: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 641–53.

L. Tan, J.T. Busby, P.J. Maziasz, and Y. Yamamoto: J. Nucl. Mater., 2013, vol. 441, pp. 713–17.

R.L. Klueh, N. Hashimoto, and P.J. Maziasz: J. Nucl. Mater., 2007, vols. 367–370, pp. 48–53.

Abe F (2008) Sci. Technol. 9(2):15.

M. Song, C. Sun, Z. Fan, Y. Chen, R. Zhu, K.Y. Yu, K.T. Hartwig, H. Wang, and X. Zhang: Acta Mater., 2016, vol. 112, pp. 361–77.

L. Tan, D.T. Hoelzer, J.T. Busby, M.A. Sokolov, and R.L. Klueh: J. Nucl. Mater., 2012, vol. 422, pp. 45–50.

L. Tan, Y. Yang, and J.T. Busby: J. Nucl. Mater., 2013, vol. 442, pp. S13–S17.

J. Pešička, R. Kužel, A. Dronhofer, and G. Eggeler: Acta Mater., 2003, vol. 51, pp. 4847–62.

E. Cerri, E. Evangelista, S. Spigarelli, and P. Bianchi: Mater. Sci. Eng. A, 1998, vol. 245, pp. 285–92.

K. Laha, K.S. Chandravathi, P. Parameswaran, K. B. S. Rao, and S.L. Mannan: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 58–68

Triratna Shrestha, Mehdi Basirat, Indrajit Charit, Gabriel P. Potirniche, and Karl K. Rink: Mater. Sci. Eng. A, 2013, vol. 565, pp. 382–91.

S. Hollner, B. Fournier, J. Le Pendu, T. Cozzika, I. Tournié, J.-C. Brachet, and A. Pineau: J. Nucl. Mater., 2010, vol. 405, pp. 101–08.

D.V.V. Satyanarayana, G. Malakondaiah, C. Phaniraj, and D.S. Sarma: Mater. Sci. Technol., 2009, vol. 25 (8), pp. 953–59.

C. Phaniraj, M. Nandagopal, S.L. Mannan, and P. Rodriguez: Acta Metall. Mater., 1991, vol. 39 (7), pp. 1651–56.

T.C. Totemeier, H. Tian, and J.A. Simpson: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1519–25.

Sakthivel T, Shruti P, Parameswaran P, Rao GVSN, Laha K, and Rao TS (2016): Trans. Ind. Inst. Met., 1:23

Irina Fedorova, Alla Kipelova, Andrey Belyakov, and Rustam Kaibyshev: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 128–35.

T. Sakthivel, S. P. Selvi, and K. Laha: Mater. Sci. Eng. A, 2015, vol. 640, pp. 61–71.

P.G. McVetty: Mech. Eng., 1934, vol. 56, p. 149.

F. Garofalo: Fundamentals of Creep and Creep Rupture in Metals, Macmillan, New York, NY, 1965.

J.B. Conway: Numerical Methods for Creep and Rupture Analysis, Gordon & Breach, New York, NY, 1968.

J.B. Conway and M.J. Mullikin: Trans. TMS-AIME, 1966, 242, p. 1496.

W.J. Evans and B. Wilshire: Trans. TMS-AIME, 1968, 242, p. 2514.

G.A. Webster, A.P.D. Cox, and J.E. Dorn: Met. Sci. J., 1969, vol. 3, p. 221.

P.W. Davies, W.J. Evans, K.R. Williams, and B. Wilshire: Scripta Metall., 1969, vol. 3, pp. 671–74.

P.W. Davies and K.R. Williams: Acta Metall., 1969, vol. 17, pp. 897–903.

F. Dobes and J. Cadek: Kov. Mater., 1981, vol. 19, p. 31.

Acknowledgments

The authors wish to thank Dr. A. K. Bhaduri, Director, Indira Gandhi Centre for Atomic Research, Kalpakkam, for his keen interest in the work and encouragement. The authors acknowledge the Board of Research in Nuclear Sciences (BRNS), Department of Atomic Energy (DAE), Government of India, for providing financial support (Project No. 36(2)/14/42/2014-BRNS) to carry out this work. The authors also acknowledge Dr. N. Srinivasan, Head, Metal Working Group, DMRL, Hyderabad, for extending the hot-rolling facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 7, 2017.

Rights and permissions

About this article

Cite this article

Shruti, P., Sakthivel, T., Rao, G.V.S.N. et al. The Role of Thermomechanical Processing in Creep Deformation Behavior of Modified 9Cr-1Mo Steel. Metall Mater Trans A 50, 4582–4593 (2019). https://doi.org/10.1007/s11661-019-05364-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05364-0