Abstract

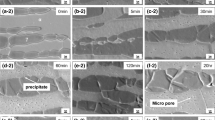

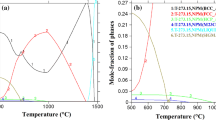

UNS S32003 materials were aged at temperatures in the range of 873 K to 1173 K (600 °C to 900 °C) for 30 minutes and 2 hours. Nitrides were found to precipitate along the ferrite/austenite phase boundaries and within the ferrite phase. The precipitation kinetics was the fastest at 1073 K (800 °C), at which temperature the Cr-depleted zones were observed to be in the vicinity of the precipitates. Precipitation and resultant Cr-depleted zone led to the highest pitting susceptibility of the UNS S32003, aged at 1073 K (800 °C), when tested in 0.6 mol/L NaCl solution. To observe the precipitation evolution, the UNS S32003 specimens were aged at 973 K (700 °C) for different time periods for up to 120 hours. Within aging time up to 24 hours at 973 K (700 °C), only nitrides precipitates were observed and an intermetallic phase was observed after 120 hours of aging along with an increase in the percentage of precipitates. Pitting potential dropped with increasing aging time and metastable pitting rate increased with longer aging time period, both indicating a negative effect of aging on pitting corrosion resistance of the lean duplex stainless steel UNS S32003.

Similar content being viewed by others

References

A. Bhattacharya and P. M. Singh, J. Fail. Anal. Prev. 2007, vol. 7, pp. 371-377.

V. Muthupandi, P. Srinivasan, S. K. Seshadri, S. Sundaresan, Mater. Sci. Eng. A 2003, 358, 9-16.

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa and H. Maza, Materials Characterization 2008, vol. 59, pp. 447-53.

N Leif, Welding in the World 2012, 56, 65-76.

L. Zhang, W. Zhang, Y. Jiang, B. Deng, D. Sun and J. Li, Electrochim. Acta 2009, vol. 54, pp. 5387-92.

Y. Yang, H. Tan, Z. Zhang, Z. Wang, Y. Jiang, L. Jiang and J. Li, CORROSION 2012, vol. 69, pp. 167-73.

L. He and P.M. Singh, In CORROSION 2017, (NACE International: New Orleans, Louisiana, USA, 2017), p 8.

D. C. dos Santos and R. Magnabosco, Metall. Mater. Trans. A 2016, vol. 47, pp. 1554-65.

J. Michalska and M. Sozańska, Mater. Charact. 2006, vol. 56, pp. 355-62.

I. Calliari, M. Pellizzari, M. Zanellato and E. Ramous, J. Mater. Sci. 2011, vol. 46, p. 6916.

H. Sieurin, R. Sandström, Mater. Sci. Eng. A 2007, 444, 271-76.

A. Bhattacharya and P. M. Singh, Metall. Mater. Trans. A 2009, vol. 40, pp. 1388-99.

M. E. Wilms, V. J. Gadgil, J. M. Krougman and F. P. Ijsseling, Corros. Sci. 1994, vol. 36, pp. 871-81.

C. J. Park, V. S. Rao and H. S. Kwon, CORROSION 2005, vol. 61, pp. 76-83.

J.-Y. Maetz, S. Cazottes, C. Verdu and X. Kleber, Metall. Mater. Trans. A 2016, vol. 47, pp. 239-53.

M. Naghizadeh and M. H. Moayed, Corrosion Science 2015, vol. 94, pp. 179-89.

Z. Wei, J. Laizhu, H. Jincheng and S. Hongmei, Materials Characterization 2009, vol. 60, pp. 50-55.

Z. Zhang, H. Zhao, H. Zhang, Z. Yu, J. Hu, L. He and J. Li, Corros. Sci. 2015, vol. 93, pp. 120-25.

L. Zhang, Y. Jiang, B. Deng, W. Zhang, J. Xu and J. Li, Materials Characterization 2009, vol. 60, pp. 1522-28.

K. Ravindranath and S. N. Malhotra, Corros. Sci. 1995, vol. 37, pp. 121-32.

B. Deng, Z. Wang, Y. Jiang, T. Sun, J. Xu and J. Li, Corrosion Science 2009, vol. 51, pp. 2969-75.

B. Deng, Z. Wang, Y. Jiang, H. Wang, J. Gao and J. Li, Electrochim. Acta 2009, vol. 54, pp. 2790-94.

A. Bhattacharya and P. M. Singh, CORROSION 2008, vol. 64, pp. 532-40.

L. Pezzato, M. Lago, K. Brunelli, M. Breda and I. Calliari, J. Mater. Eng. Perform. 2018, vol. 27, pp. 3859-68.

I. Calliari, M. Dabalà, E. Ramous and G. Straffelini, Mater. Sci. Forum 2009, vol. 604-605, pp. 419-26.

T. H. Chen, K. L. Weng and J. R. Yang, Mater. Sci. Eng. A 2002, 338, 259-70.

E. A. Melo and R. Magnabosco, Metall. Mater. Trans. A 2017, vol. 48, pp. 5273-84.

Acknowledgments

Author (Liang He) would like to thank the Renewable Bioproducts Institute at Georgia Tech for the PSE graduate student fellowship. The authors would also like to acknowledge the member companies of the Renewable Bioproducts Institute at Georgia Institute of Technology for a partial financial support for this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 23, 2018.

Rights and permissions

About this article

Cite this article

He, L., Wirian, L. & Singh, P.M. Effects of Isothermal Aging on the Microstructure Evolution and Pitting Corrosion Resistance of Lean Duplex Stainless Steel UNS S32003. Metall Mater Trans A 50, 2103–2113 (2019). https://doi.org/10.1007/s11661-019-05189-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05189-x