Abstract

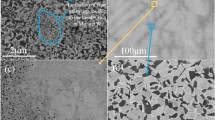

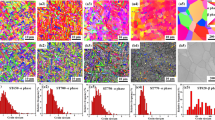

Gradient materials have been reported to have superior strength–ductility combinations. In this study, gradient α″ martensite were introduced along the radial direction of cylindrical Ti-10V-2Al-3Fe (Ti-1023) samples by torsional straining, which simultaneously improved strength and ductility. The torsional strain gradient produced martensite gradient with increasing density and decreasing thickness from center to surface. α″ martensite had parallel and V-shaped morphology, which not only divided coarse β grains into finer β blocks but also blocked dislocation slip. In addition, dislocation slip in the α″ martensite and β blocks led to grain refinement. The formation of geometrically necessary dislocation (GNDs) and the increasing shear stress required for martensitic transformation contributed to high strain hardening. An optimal gradient distribution exists in torsion-processed samples for the optimal mechanical properties.

Similar content being viewed by others

References

K. Lu, Sci, 2014, vol. 345, pp. 1455-1456.

X. Wu, P. Jiang, L. Chen, F. Yuan, Y.T. Zhu, P Natl Acad Sci, 2014, vol. 111, pp. 7197-7201.

R. Thevamaran, O. Lawal, S. Yazdi, S.-J. Jeon, J.-H. Lee, E.L. Thomas, Sci, 2016, vol. 354, pp. 312-316.

I. Ovid’ko, R. Valiev, Y. Zhu, Prog Mater Sci, 94: 462 (2018)

X. Bian, F. Yuan, Y. Zhu, X. Wu, Mater Res Lett, 2017, 5, 501-507.

X. Wu, Y. Zhu, Mater Res Lett, 2017, vol. 5, pp. 527-532.

X. Wu, P. Jiang, L. Chen, J. Zhang, F. Yuan, Y. Zhu, Mater Res Lett, 2014, vol. 2, pp. 185-191.

M. Yang, Y. Pan, F. Yuan, Y. Zhu, X. Wu, Mater Res Lett, 2016, vol. 4, pp. 145-151.

A. Chen, J. Liu, H. Wang, J. Lu, Y.M. Wang, Mater Sci Eng: A,2016, vol. 667, pp. 179-188.

X. Liu, H. Zhang, K. Lu, Sci, 2013, vol. 342, pp. 337-340.

H. Wang, N. Tao, K. Lu, Scripta Mater, 2013, vol. 68, pp. 22-27.

Z. Ma, J. Liu, G. Wang, H. Wang, Y. Wei, H. Gao, Sci Rep, 2016, vol. 6, pp. 22156.

A. Chen, H. Ruan, J. Wang, H. Chan, Q. Wang, Q. Li, J. Lu, Acta Mater, 2011, vol. 59, pp. 3697-3709.

Y. Wei, Y. Li, L. Zhu, Y. Liu, X. Lei, G. Wang, Y. Wu, Z. Mi, J. Liu, H. Wang, Nat Commun, 2014, vol. 5, pp 3580.

L. Lu, X. Chen, X. Huang, K. Lu, Sci, 2009, vol. 323, pp. 607-610.

H. Wang, N. Tao, K. Lu, Acta Mater, 2012, vol. 60, pp. 4027-4040.

C. Shao, P. Zhang, Y. Zhu, Z. Zhang, Y. Tian, Z. Zhang, Acta Mater, 2017, vol. 145, pp.413-428.

Y. Kulkarni, R.J. Asaro, D. Farkas, Scripta Mater, 2009, vol. 60, pp. 532-535.

J. Moering, X. Ma, G. Chen, P. Miao, G. Li, G. Qian, S. Mathaudhu, Y. Zhu, Scripta Mater, 2015, vol. 108, pp.100-103.

A. Bhattacharjee, V. Varma, S. Kamat, A. Gogia, S. Bhargava, Metall Mater Trans A, 2006, vol. 37, pp. 1423-1433.

A. Zafari, K. Xia, Mater Sci Eng: A, 2018, vol. 724, pp. 75-79.

D. Qin, Y. Lu, D. Guo, L. Zheng, Q. Liu, L. Zhou, Mater Sci Eng: A, 2013, vol. 587, pp. 100-109.

Z. Wyatt, S. Ankem, J Mater Sci, 2010, vol. 45, pp. 5022-5031.

W. Xu, K. Kim, J. Das, M. Calin, J. Eckert, Scripta Mater, 2006, vol. 54, pp. 1943-1948.

A. Paradkar, S. Kamat, A. Gogia, B. Kashyap, Metall Mater Trans A, 2008, vol. 39, pp. 551-558.

C. Li, X. Wu, J. Chen, S. van der Zwaag, Mater Sci Eng: A,2011, vol. 528, pp. 5854-5860.

F. Sun, J. Zhang, M. Marteleur, C. Brozek, E. Rauch, M. Veron, P. Vermaut, P. Jacques, F. Prima, Scripta Mater, 2015, vol. 94, pp. 17-20

S. Sadeghpour, S. Abbasi, M. Morakabati, A. Kisko, L. Karjalainen, D. Porter, Scripta Mater, 2018, vol.145, pp. 104-108.

X. Ma, F. Li, J. Cao, J. Li, Z. Sun, G. Zhu, S. Zhou, Mater Sci Eng: A, 2018, vol. 710, pp. 1-9.

P. Barriobero-Vila, J. Gussone, K. Kelm, J. Haubrich, A. Stark, N. Schell, G. Requena, Mater Sci Eng: A, 2018, vol. 717, pp. 134-143.

T. Yao, K. Du, H. Wang, Z. Huang, C. Li, L. Li, Y. Hao, R. Yang, H. Ye, Acta Mater, 2017, vol. 133, pp. 21-29.

T. Fang, W. Li, N. Tao, K. Lu, Sci, 2011, 331, 1200177.

X. Ma, F. Li, J. Cao, J. Li, H. Chen, C. Zhao, Mater Design, 2017, vol. 114, pp. 271-281.

N. Guo, X. Li, M. Xiao, R. Xin, L. Chai, B. Song, H. Yu, L. Li, Adv Eng Mater, 2016, vol. 18, pp. 1738-1746.

C. Wang, F. Li, J. Li, J. Dong, F. Xue, Mater Sci Eng: A, 2014, vol. 598, pp. 7-14.

L. Sun, K. Muszka, B. Wynne, E. Palmiere, Palmiere, Acta Mater, 2014, vol.66, pp. 132-149.

N. Guo, Z. Zhang, Q. Dong, H. Yu, B. Song, L. Chai, C. Liu, Z. Yao, M.R. Daymond, Mater Design, 2018, vol. 143, pp.150-159.

X. Ma, F. Li, J. Cao, Z. Sun, Q. Wan, J. Li, Z. Yuan, J Alloy Compd, 2017, vol. 703, pp. 298-308.

Y. Estrin, A. Vinogradov, Acta mater, 2013, vol. 61, pp. 782-817.

R. Pippan, F. Wetscher, M. Hafok, A. Vorhauer, I. Sabirov, Adv Eng Mater, 2006, vol. 8, pp. 1046-1056.

W. Chen, Q. Sun, L. Xiao, J. Sun, Metall Mater Trans A, 2012, vol. 43, pp. 316-326.

X. Ma, F. Li, X. Fang, Z. Li, Z. Sun, J. Hou, J. Cao, J Alloy Compd, 2019, vol. 784, pp.111-116.

W. Xu, X. Wu, M. Calin, M. Stoica, J. Eckert, K. Xia, Scripta Mater, 60, 1012-1015 (2009)

T. Duerig, J. Albrecht, D. Richter, P. Fischer, Acta Metall, 1982, vol. 30, pp. 2161-2172.

Y. Chai, H. Kim, H. Hosoda, S. Miyazaki, Acta Mater, 2009, vol. 57, pp. 4054-4064.

M. Kružík, A. Mielke, T. Roubíček, Meccanica, 2005, vol. 40, pp. 389-418.

A. Zafari, X. Wei, W. Xu, K. Xia, Acta Mater, 2015, vol. 97, pp. 146-155.

W. Xu, K. Kim, J. Das, M. Calin, B. Rellinghaus, J. Eckert, Appl Phys Lett, 2006, vol. 89, pp.031906.

S. Sadeghpour, S. Abbasi, M. Morakabati, J Alloy Compd, 2015, vol. 650, pp.22-29.

T. Grosdidier, M.-J. Philippe, Mater Sci Eng: A, 2000, vol. 291, pp. 218-223.

D. Ping, Y. Yamabe-Mitarai, C. Cui, F. Yin, M. Choudhry, Appl Phys Lett, 2008, vol. 93, pp. 151911.

C. Wei, Y. Shanshan, L. Ruolei, S. Qiaoyan, X. Lin, S. Jun, Rare Metal Mat Eng, 2015, vol. 44, pp. 1601-1606.

Y. Ren, F. Wang, S. Wang, C. Tan, X. Yu, J. Jiang, H. Cai, Mater Sci Eng: A, 2013, vol. 562, pp. 137-143.

Acknowledgments

This work was supported by the China Scholarship Council (No. 201706290055, awarded to Xinkai Ma for two-year abroad study at the North Carolina State University); the National Natural Science Foundation of China (Grant Nos. 51275414, 51605387); the Fundamental Research Funds for the Central Universities with Grant No. 3102015BJ (II) ZS007; the Research Fund of the State Key Laboratory of Solidification Processing (NWPU), China (Grant No.130-QP-2015); and the Seed Foundation of Innovation and Creation for Graduate Students in Northwestern Polytechnical University (No. Z2018076).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 27, 2018.

Rights and permissions

About this article

Cite this article

Ma, X., Li, F., Sun, Z. et al. Achieving Gradient Martensite Structure and Enhanced Mechanical Properties in a Metastable β Titanium Alloy. Metall Mater Trans A 50, 2126–2138 (2019). https://doi.org/10.1007/s11661-019-05157-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05157-5