Abstract

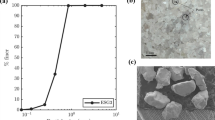

The systematic study of the particulate dirt characteristics on heat exchanging surface can provide theoretical guidance for defouling. In this paper, four main compositions of particulate dirt in the treated city sewage (i.e., CaCO3, MgO, CaSO4 and SiO2) are selected as the research objects. The effects of different working conditions, characteristics of particles on the growth rules of particulate dirt and the synergistic fouling by different particles are researched by thermal resistance method experimentally, while the microstructures of the dirt are observed by Scanning Electron Microscope (SEM). The asymptotic values of both dirt thermal resistance and the scaling rate decrease with the increasing of working fluid velocity, while the two asymptotic values increase with the increasing particle size and particle concentration. Although the working fluid import temperature shows a weaker influence on the thermal resistance, but the increase of working fluid import temperature can retard the fouling rate. Among the stable values of the thermal resistances of four types of fouling, SiO2 is the largest and MgO is the smallest. The synergistic fouling by different types of particles results in the denser structure of mixed fouling.

Similar content being viewed by others

References

Chamra L.M., Webb R.L., Modeling liquid-side particulate fouling in enhanced tubes. International Journal of Heat & Mass Transfer, 1994, 37(4): 571–579.

Wei L., Shi W., Jiang X., et al., Analysis on internal solid-liquid two-phase flow in the impellers of sewage pump. Procedia Engineering, 2012, 31(1): 170–175.

Piglione M.C., Fontana D., Vanni M., Simulation of particle deposition in human central airways. European Journal of Mechanics - B/Fluids, 2012, 31(1): 91–101.

Kuruneru S.T.W., Sauret E., Vafai K., et al., Analysis of particle-laden fluid flows, tortuosity and particle-fluid behaviour in metal foam heat exchangers. Chemical Engineering Science, 2017, 172: 677–687.

Kasper R., Turnow J., Kornev N., Numerical modeling and simulation of particulate fouling of structured heat transfer surfaces using a multiphase Euler-Lagrange approach. International Journal of Heat & Mass Transfer, 2017, 115: 932–945.

Bennett C.A., A theory describing sedimentation particulate fouling thresholds inside heat exchanger tubes. Heat Transfer Engineering, 2016, 37(5): 468–474.

Kuruneru S.T.W., Sauret E., Vafai K., et al., Analysis of particle-laden fluid flows, tortuosity and particle-fluid behaviour in metal foam heat exchangers. Chemical Engineering Science, 2017, 172: 677–687.

Shen C., Wang Y., Gao R., et al., An improved modeling method of water-side fouling in enhanced tubes of condensers in application of cooling water tower. Journal of Thermal Science, 2019, 28(1): 30–39.

Shen C., Wang Y., Zhao Z., et al., Decoupling analysis on the variations of liquid velocity and heat flux in the test of fouling thermal resistance. International Journal of Heat & Mass Transfer, 2018, 123: 227–238.

Shen C., Wang L., Ford S.E., et al., A novel fouling measurement system: Part I. design evaluation and description. International Journal of Heat & Mass Transfer, 2017, 110: 940–949.

Shen C., Wang L., Ford S.E., et al., A novel fouling measurement system: Part II. Commissioning. International Journal of Heat & Mass Transfer, 2017, 110: 950–961.

Shen C., Cirone C., Wang X., Uncertainty analysis: Design of a fouling test device for the liquid-to-refrigerant heat exchangers. Applied Thermal Engineering, 2015, 85: 148–159.

Lee E., Jeon J., Kang H., et al., Thermal resistance in corrugated plate heat exchangers under crystallization fouling of calcium sulfate (CaSO4). International Journal of Heat & Mass Transfer, 2014, 78(11): 908–916.

Mesticou Z., Kacem M., Dubujet P., Influence of ionic strength and flow rate on silt particle deposition and release in saturated porous medium: experiment and modeling. Transport in Porous Media, 2014, 103(1): 1–24.

Mayer M., Bucko J., Benzinger W., et al., Crystallization fouling in experimental micro heat exchangers-optical and thermal investigations. Experimental Heat Transfer, 2013, 26(5): 487–502.

Xu Z.M., Wang J.T., Wang Y.H., Effect of temperature on paticulate fouling characteristics of nanometer magnesia. Journal of Thermal Science and Technology, 2016, 15(1): 52–58. (in Chinese)

Zhang Y.L., Sun M., Liu Z.D., et al., Nanoparticles and microparticles fouling surface characteristics and their equivalent relationship. Chemical Industry and Engineering Progress, 2015, 34(1): 266–272. (in Chinese)

Li H.X., Li G.Q., Li W., Analysis of particle fouling in tube. Journal of Zhejiang University (Science Engineering), 2012, 46(9): 1671–1677. (in Chinese)

Nikkhah V., Sarafraz M.M., Hormozi F., et al., Particulate fouling of CuO–water nanofluid at isothermal diffusive condition inside the conventional heat exchangerexperimental and modeling. Experimental Thermal & Fluid Science, 2015, 60: 83–95.

Wang M., Mondal S., Griffiths I.M., The role of fouling in optimizing direct-flow filtration module design. Chemical Engineering Science, 2017, 163: 215–222.

Sun Y., Zhang Y., Barker D., et al., Experimental evaluation of air-side particulate fouling performance of heat exchangers. Ashrae Transactions, 2012, 45(6): 118–126.

Mayer M., Bucko J., Benzinger W., et al., The impact of crystallization fouling on a microscale heat exchanger. Experimental Thermal & Fluid Science, 2012, 40(7): 126–131.

Wang X.D., Liu P., Wang L., et al., Analysis characteristics of dissolved organic matters in the secondary effluent of municipal waste water. Chinese Journal of Environmental Engineering, 2014, 8(6): 2186–2190. (in Chinese)

Xu Z.M., Zhang M.X., Zhang Y.L., et al., Numerical simulation of fouling characteristics of micro-particles. Chemical Engineering & Machinery, 2015, 42(6): 828–834. (in Chinese)

Zubair S.M., Qureshi B.A., A probabilistic fouling and cost model for plate-and-frame heat exchangers. International Journal of Energy Research, 2010, 30(1): 1–17.

Wang Z.Y., Liu Z.M., Xia X.T., Measurement error and uncertainty evaluation. Science Press, Beijing, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Q., Zhang, Z., Yao, E. et al. Experimental Study of the Particulate Dirt Characteristics on Pipe Heat Transfer Surface. J. Therm. Sci. 28, 1054–1064 (2019). https://doi.org/10.1007/s11630-019-1183-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-019-1183-8