Abstract

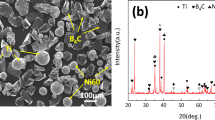

Using plasma build-up welding technology, Ni60, WC, Cr3C2, and TiC composite powders were clad on the surface of the substrate in a certain proportion according to the metallurgical bonding method to increase the bond strength between the coating and the substrate. Scanning electron microscopy and energy dispersive spectroscopy were used to observe the microstructure of the surfacing layer and the chemical composition of the sample. The hardness and wear resistance of the surfacing layer were tested and analyzed by the HV-1000 hardness tester and the impact wear device. The results showed that in the microstructure, fishbone, spider-web, and floral-like structures appeared in the surfacing layer. When the micro-hardness was tested, the depth of the indentation reflected the hardness of the surfacing layer. When analyzing wear resistance, the amount of wear increases with time.

Similar content being viewed by others

References

Liu YF, Mu JS, Xu XY, et al. Microstructure and Dry–sliding Wear Properties of TiC–reinforced Composite Coating Prepared by Plasma–transferred Arc Weld–surfacing Process[J]. Materials Science & Engineering A, 2007, 458(1–2): 366–370

Yuan J, Ma C, Yang S, et al. Improving the Wear Resistance of HVOF Sprayed WC–Co Coatings by Adding Submicron–sized WC Particles at the Splats’ Interfaces[J]. Surface & Coatings Technology, 2016, 285: 17–23

Huang S, Sun D, Wang W. Microstructures and Properties of Ni Based Composite Coatings Prepared by Plasma Spray Welding with Mixed Powders[J]. International Journal of Refractory Metals & Hard Materials, 2015, 52: 36–43

Bag A, Ray KK, Dwarkadasa ES. Influence of Martensite Content and Morphology on the Toughness and Fatigue Behavior of High–martensite Dual–phase Steels. Metall Mater Trans 1999, 30(A): 1 193–1 202

Stolarski T A, Tobe S. The Effect of Spraying Distance on Wear Resistance of Molybdenum Coatings[J]. Wear, 2001, 249(12): 1 096–1 102

Sudha C, Shankar P, Rao RVS, et al. Microchemical and Microstructural Studies in a PTA Weld Overlay of Ni–Cr–Si–B alloy on AISI304L Stainless Steel[J]. Surface & Coatings Technology, 2008, 202(10): 2 103–2 112

Chen D, Liu D, Liu Y, et al. Microstructure and Fretting Wear Resistance of γ/TiC Composite Coating in Situ Fabricated by Plasma Transferred Arc Cladding[J]. Surface & Coatings Technology, 2014, 239(239): 28–33

Zeng Z, Wang L, Chen L, et al. The Correlation between the Hardness and Tribological Behaviour of Electroplated Chromium Coatings Sliding Against Ceramic and Steel Counterparts[J]. Surface & Coatings Technology, 2006, 201(6): 2 282–2 288

Efremenko VG, Shimizu K, Noguchi T, et al. Impact–Abrasive–Corrosion Wear of Fe–based Alloys: Influence of Microstructure and Chemical Composition Upon Wear Resistance[J]. Wear, 2013, 305 (1–2): 155–165

Qi X, Zhu S, Ding H, et al. Microstructure and Wear Behaviors of WC–12%Co Coating Deposited on Ductile Iron by Electric Contact Surface Strengthening[J]. Applied Surface Science, 2013, 282(10): 672–679

Çelik ON. Microstructure and Wear Properties of WC Particle Reinforced Composite Coating on Ti6Al4V Alloy Produced by the Plasma Transferred Arc Method[J]. Applied Surface Science, 2013, 274(274): 334–340

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Scientific Research Foundation of Sha ndong University of Science and Technology for Recruited Talents (No.2014RCJJ041) and the National Natural Science Foundation of China(51774199)

Rights and permissions

About this article

Cite this article

Zhu, J., Yu, H. & Zhang, L. Preparation and Characterization of Ni60-Cr3C2-WC/TiC Plasma Welding Surfacing Layer. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 1402–1406 (2018). https://doi.org/10.1007/s11595-018-1982-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1982-x