Abstract

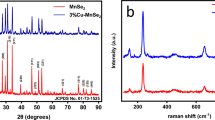

Various synthesis methods have been developed to synthesize mixed metal oxide cathode materials, whereas the scale-up production is hindered by issues of complicated processes, high cost, and inhomogeneity of the prepared materials. Herein, a facile, low-cost, and scalable synthesis route using M2(OH)2(C8H4O4)-class metal-organic frameworks (PTA-based MOFs) as precursors has been explored to synthesize LiNi0.5Mn1.5O4 materials with homogeneity and high crystallinity. Bimetallic PTA-based MOFs were first prepared by the reaction of metal acetates and PTA in the aqueous solution at room temperature. After thermal treatment of PTA-based MOFs, bimetal oxides (Ni-Mn-O) with the inherited morphology of porous nanoplates consisting of 20–30-nm nanoparticles were obtained. The LiNi0.5Mn1.5O4 materials prepared by calcination of Ni-Mn-O with lithium salts exhibit excellent rate capability and cycling performance, delivering a specific capacity of 115.9 mAh g−1 at 20 C and retaining 83.8% after 500 cycles. This work opens a new way for fabrication of PTA-based MOFs and mixed metal oxides as cathode materials for lithium-ion batteries.

Similar content being viewed by others

References

Cai Y, Huang SZ, She FS et al (2016) Facile synthesis of well-shaped spinel LiNi0.5Mn1.5O4 nanoparticles as cathode materials for lithium ion batteries. RSC Adv 6(4):2785–2792. doi:10.1039/c5ra21723g

Yi TF, Xie Y, Zhu YR et al (2012) High rate micron-sized niobium-doped LiMn1.5Ni0.5O4 as ultra high power positive-electrode material for lithium-ion batteries. J Power Sources 211:59–65. doi:10.1016/j.jpowsour. 2012.03.095

Cho HM, Chen MV, MacRae AC et al (2015) Effect of surface modification on nano-structured LiMn1.5Ni0.5O4 spinel materials. ACS Appl Mater. Interfaces 7(30):16231–16239. doi:10.1021/acsami.5b01392

Wang HL, Tan TA, Yang P et al (2011) High-rate performances of the Ru-doped spinel LiNi0.5Mn1.5O4: effects of doping and particle size. J Phys Chem C 115(13):6102–6110. doi:10.1021/jp110746w

Liu GQ, Wen L, Wang X et al (2011) Effect of the impurity LixNi1−xO on the electrochemical properties of 5V cathode material LiMn1.5Ni0.5O4. J Alloys Compd 509(38):9377–9381. doi:10.1016/j.jallcom. 2011.07.045

Zhong GB, Wang YY, Yu YQ et al (2012) Electrochemical investigations of the LiNi0.45M0.10Mn1.45O4 (M=Fe, Co, Cr) 5V cathode materials for lithium ion batteries. J Power Sources 205:385–393. doi:10.1016/j.jpowsour. 2011.12.037

Sun P, Ma Y, Zhai T et al (2016) High performance LiMn1.5Ni0.5O4 cathode by Al-coating and Al3+-doping through a physical vapor deposition method. Electrochim Acta 191:237–246. doi:10.1016/j.electacta. 2016.01.087

Xu J, Xia Q, Chen F et al (2016) Facilely solving cathode/electrolyte interfacial issue for high-voltage lithium ion batteries by constructing an effective solid electrolyte interface film. Electrochim Acta 191:687–694. doi:10.1016/j.electacta. 2016.01.138

Wang Y, Yang G, Yang Z et al (2013) High power and capacity of LiMn1.5Ni0.5O4 thin films cathodes prepared by pulsed laser deposition. Electrochim Acta 102:416–422. doi:10.1016/j.electacta. 2013.04.018

Chen ZX, Qiu S, Cao YL et al (2012) Surface-oriented and nanoflake-stacked LiMn1.5Ni0.5O4 spinel for high-rate and long-cycle-life lithium ion batteries. J Mater Chem 22(34):17768–17772. doi:10.1039/c2jm33338d

Choi SH, Hong YJ, Kang YC (2013) Yolk-shelled cathode materials with extremely high electrochemical performances prepared by spray pyrolysis. Nano 5(17):7867–7871. doi:10.1039/c3nr01675g

Cabana J, Casas-Cabanas M, Omenya FO et al (2012) Composition-structure relationships in the Li-ion battery electrode material LiNi0.5Mn1.5O4. Chem Mater 24:2952–2964. doi:10.1021/cm301148d

Song J, Shin DW, Lu Y et al (2012) Role of oxygen vacancies on the performance of LiNi0.5–xMn1.5+xO4 (x= 0, 0.05, and 0.08) spinel cathodes for lithium-ion batteries. Chem Mater 24(15):3101–3109. doi:10.1021/cm301825h

Feng XY, Shen C, Fang X et al (2011) Synthesis of LiMn1.5Ni0.5O4 by solid-state reaction with improved electrochemical performance. J Alloys Compd 509(8):3623–3626. doi:10.1016/j.jallcom. 2010.12.116

Lin Y, Yang Y, Yu R et al (2014) Enhanced electrochemical performances of LiMn1.5Ni0.5O4 by surface modification with superconducting YBa2Cu3O7. J Power Sources 259:188–194. doi:10.1016/j.jpowsour. 2014.02.093

Hao X, Austin MH, Bartlett BM (2012) Two-step hydrothermal synthesis of submicron Li1+xNi0.5Mn1.5O4−δ for lithium-ion battery cathodes (x = 0.02, δ = 0.12). Dalton Trans 41(26):8067–8076. doi:10.1039/c2dt30351e

Sun Y, Yang Y, Zhao X et al (2011) Synthesis and electrochemical characterization of LiMn1.5Ni0.5O4 by one-step precipitation method with ammonium carbonate as precipitating agent. Electrochim Acta 56(17):5934–5939. doi:10.1016/j.electacta. 2011.04.113

Yang S, Chen J, Liu Y et al (2014) Preparing LiMn1.5Ni0.5O4 nanoplates with superior properties in lithium-ion batteries using bimetal-organic coordination-polymers as precursors. J Mater Chem A 2(24):9322–9330. doi:10.1039/c4ta01147c

Wang DP, Belharouak I, Koenig GM et al (2011) Growth mechanism of Ni0.3Mn0.7CO3 precursor for high capacity Li-ion battery cathodes. J Mater Chem 21(25):9290. doi:10.1039/c1jm11077b

Saha D, Wei Z, Deng S (2009) Hydrogen adsorption equilibrium and kinetics in metal–organic framework (MOF-5) synthesized with DEF approach. Sep Purif Technol 64(3):280–287. doi:10.1016/j.seppur. 2008.10.022

Ke FS, Wu YS, Deng H (2015) Metal-organic frameworks for lithium ion batteries and supercapacitors. J Solid State Chem 223:109–121. doi:10.1016/j.jssc. 2014.07.008

Nguyen HGT, Schweitzer NM, Chang CY et al (2014) Vanadium-node-functionalized UiO-66: a thermally stable MOF-supported catalyst for the gas-phase oxidative dehydrogenation of cyclohexene. ACS Catal 4(8):2496–2500. doi:10.1021/cs5001448

Sun X, Mura M, Jonkman HT et al (2012) Fabrication of a complex two-dimensional adenine–perylene-3, 4, 9, 10-tetracarboxylic dianhydride chiral nanoarchitecture through molecular self-assembly. J Phys Chem C 116(3):2493–2499. doi:10.1021/jp2095054

Hu L, Chen Q (2014) Hollow/porous nanostructures derived from nanoscale metal-organic frameworks towards high performance anodes for lithium-ion batteries. Nano 6(3):1236–1257. doi:10.1039/c3nr05192g

Zhang Z, Chen Y, He S et al (2014) Hierarchical Zn/Ni-MOF-2 nanosheet-assembled hollow nanocubes for multicomponent catalytic reactions. Angew Chem Int Ed Engl 53(46):12517–12521. doi:10.1002/anie.201406484

Wu RB, Qian XK, Zhou K et al (2014) Porous spinel ZnxCo3-xO4 hollow polyhedra templated for high-rate lithium-ion batteries. ACS Nano 8(6):6297–6303

Wang L, Zhang H, Mou C et al (2015) Dicarboxylate CaC8H4O4 as a high-performance anode for Li-ion batteries. Nano Res 8(2):523–532. doi:10.1007/s12274-014-0666-x

Gou L, Hao LM, Shi YX et al (2014) One-pot synthesis of a metal–organic framework as an anode for Li-ion batteries with improved capacity and cycling stability. J Solid State Chem 210(1):121–124. doi:10.1016/j.jssc. 2013.11.014

Geng B, Zhan F, Fang C et al (2008) A facile coordination compound precursor route to controlled synthesis of Co3O4 nanostructures and their room-temperature gas sensing properties. J Mater Chem 18(41):4977. doi:10.1039/b805378b

Zhu J, Gao Q (2009) Mesoporous MCo2O4 (M=Cu, Mn and Ni) spinels: structural replication, characterization and catalytic application in CO oxidation. Microporous Mesoporous Mater 124(1–3):144–152. doi:10.1016/j.micromeso. 2009.05.003

Lu H, Zhu S (2013) Interfacial synthesis of free-standing metal-organic framework membranes. Eur J Inorg Chem:1294–1300. doi:10.1002/ejic.201201009

Zhang K, Han X, Hu Z et al (2015) Nanostructured Mn-based oxides for electrochemical energy storage and conversion. Chem Soc Rev 44(3):699–728. doi:10.1039/c4cs00218k

Lu ZH, Dahn JR (2002) Understanding the anomalous capacity of Li/Li [NixLi(1/3−2x/3)Mn(2/3−x/3)]O2 cells using in situ X-ray diffraction and electrochemical studies. J Electrochem Soc 149(7):A815–A822. doi:10.1149/1.1480014

Sibille R, Mesbah A, Mazet T et al (2012) Magnetic measurements and neutron diffraction study of the layered hybrid compounds Mn (C8H4O4)(H2O)2 and Mn2(OH)2(C8H4O4). J Solid State Chem 186:134–141. doi:10.1016/j.jssc. 2011.12.009

Wang Z, Liu Y, Gao C et al (2015) A porous Co (OH)2 material derived from a MOF template and its superior energy storage performance for supercapacitors. J Mater Chem A 3(41):20658–20663. doi:10.1039/c5ta04663g

He S, Li Z, Wang J et al (2016) MOF-derived NixCo1−x (OH)2 composite microspheres for high-performance supercapacitors. RSC Adv 6(55):49478–49486. doi:10.1039/c6ra03992h

Mesbah A, Malaman B, Mazet T et al (2010) Location of metallic elements in (Co1−xFex)2(OH)2(C8H4O4): use of MAD, neutron diffraction and 57Fe Mössbauer spectroscopy. Cryst Eng Comm 12(10):3126–3131. doi:10.1039/b926144c

Williams GR, Crowder J, Burley JC et al (2012) The selective intercalation of organic carboxylates and sulfonates into hydroxy double salts. J Mater Chem 22(27):13600–13611. doi:10.1039/c2jm32257a

Miles DO, Jiang D, Burrows AD et al (2013) Conformal transformation of [Co (bdc)(DMF)] (Co-MOF-71, bdc = 1, 4-benzenedicarboxylate, DMF = NN-dimethylformamide) into porous electrochemically active cobalt hydroxide. Electrochem Commun 27:9–13. doi:10.1016/j.elecom. 2012.10.039

Diring S, Furukawa S, Takashima Y et al (2010) Controlled multiscale synthesis of porous coordination polymer in nano/micro regimes. Chem Mater 22:4531–4538. doi:10.1021/cm101778g

Oh JM, Hwang SH, Choy JH (2002) The effect of synthetic conditions on tailoring the size of hydrotalcite particles. Solid State Ionics 151:285–291

Wang J, Yu YY, Wu BH et al (2015) A homogeneous intergrown material of LiMn2O4 and LiNi0.5Mn1.5O4 as a cathode material for lithium-ion batteries. J Mater Chem A 3(5):2353–2360. doi:10.1039/c4ta05311g

Guzel F, Yakut H, Topal G (2008) Determination of kinetic and equilibrium parameters of the batch adsorption of Mn (II), Co (II), Ni (II) and Cu (II) from aqueous solution by black carrot (Daucus carota L.) residues. J Hazard Mater 153(3):1275–1287. doi:10.1016/j.jhazmat. 2007.09.087

Amdouni N, Zaghib K, Gendron F et al (2006) Structure and insertion properties of disordered and ordered LiNi0.5Mn1.5O4 spinels prepared by wet chemistry. Ionics 12(2):117–126. doi:10.1007/s11581-006-0021-7

Dong L, Chu Y, Sun W (2008) Controllable synthesis of nickel hydroxide and porous nickel oxide nanostructures with different morphologies. Chemistry 14(16):5064–5072. doi:10.1002/chem.200701627

Chong J, Xun SD, Song XY et al (2013) Surface stabilized LiNi0.5Mn1.5O4 cathode materials with high-rate capability and long cycle life for lithium ion batteries. Nano Energy 2(2):283–293. doi:10.1016/j.nanoen. 2012.09.013

Gu X, Li X, Xu L et al (2012) Synthesis of spinel LiNixMn2-xO4 (x=0, 0.1, 0.16) and their high rate charge-discharge performances. Int J Electrochem Sci 7:2504–2512

Fang H, Li L, Li G (2007) A low-temperature reaction route to high rate and high capacity LiNi0.5Mn1.5O4. J Power Sources 167(1):223–227. doi:10.1016/j.jpowsour. 2007.02.015

Raja MW, Mahanty S, Basu RN (2009) Multi-faceted highly crystalline LiMn2O4 and LiNi0.5Mn1.5O4 cathodes synthesized by a novel carbon exo-templating method. Solid State Ionics 180(23–25):1261–1266. doi:10.1016/j.ssi. 2009.06.016

Hirayama M, Ido H, Kim K et al (2010) Dynamic structural changes at LiMn2O4 electrolyte interface during lithium battery reaction. J Am Chem Soc 132(43):15268. doi:10.1021/ja105389t

Xiao Y, Xiang W, Zhang J et al (2016) Synthesis of spinel LiNi0.5Mn1.5O4 as advanced cathode via a modified oxalate co-precipitation method. Ionics 22(8):1361–1368. doi:10.1007/s11581-016-1659-4

Pan J, Deng J, Yao Q et al (2015) Novel LiNi0.5Mn1.5O4 porous microellipsoids as high-performance cathode materials for lithium ion batteries. J Power Sources 288:353–358. doi:10.1016/j.jpowsour. 2015.04.133

Zhang X, Cheng F, Yang J et al (2013) LiNi0.5Mn1.5O4 porous nanorods as high-rate and long-life cathodes for Li-ion batteries. Nano Lett 13(6):2822–2825. doi:10.1021/nl401072x

Qian YX, Deng YF, Shi ZC et al (2013) Sub-micrometer-sized LiNi0.5Mn1.5O4 spheres as high rate cathode materials for long-life lithium ion batteries. Electrochem Commun 27:92–95. doi:10.1016/j.elecom. 2012.11.004

Zhu X, Li X, Zhu Y et al (2014) Porous LiNi0.5Mn1.5O4 microspheres with different pore conditions: preparation and application as cathode materials for lithium-ion batteries. J Power Sources 261:93–100. doi:10.1016/j.jpowsour. 2014.03.047

Kunduraci M, Al-Sharab JF, Amatucci GG (2006) High-power nanostructured LiMn2-xNixO4 high-voltage lithium-ion battery electrode materials: electrochemical impact of electronic conductivity and morphology. Chem Mater 18:3585–3592. doi:10.1021/cm060729s

Acknowledgements

This work was supported by the National High Technology Research and Development Program of China (Grant No. 2013AA050901).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 1475 kb)

Rights and permissions

About this article

Cite this article

Yang, S., Ren, W. & Chen, J. Facile synthesis of spinel LiNi0.5Mn1.5O4 cathode materials using M2(OH)2(C8H4O4)-class metal-organic frameworks. Ionics 23, 2969–2980 (2017). https://doi.org/10.1007/s11581-017-2102-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2102-1