Abstract

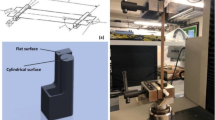

The skirt-to-shell junction weld on coke drums is susceptible to fatigue failure due to severe thermal cyclic stresses. One method to decrease junction stress is to add slots near the top of the skirt, thereby reducing the local stiffness close to the weld. The most common skirt slot design is thin relative to its circumferential spacing. A new slot design, which is significantly wider, is proposed. In this study, thermal-mechanical elastoplastic 3-D finite element models of coke drums are created to analyze the effect of different skirt designs on the stress/strain field near the shell-to-skirt junction weld, as well as any other critical stress locations in the overall skirt design. The results confirm that the inclusion of the conventional slot design effectively reduces stress in the junction weld. However, it has also been found that the critical stress location migrates from the shell-to-skirt junction weld to the slot ends. A method is used to estimate the fatigue life near the critical areas of each skirt slot design. It is found that wider skirt slots provide a significant improvement on fatigue life in the weld and slot area.

Similar content being viewed by others

References

American Petroleum Institute. 1996API Coke Drum Survey Final Report. 2003

Ramos A, Rios C C, Vargas J, et al. Mechanical integrity evaluation of delayed Coke drums. In: Proceedings of ASME 1997 Pressure Vessels and Piping Conference on Fitness for Adverse Environments in Petroleum and Power Equipment. 1997, 359: 291–298

Ramos A, Rios C C, Johnsen E, et al. Delayed coke drum assessment using field measurements & FEA. In: Proceedings of ASME/JSME 1998 Joint Pressure Vessels and Piping Conference on Analysis and Design of Composite, Process, and Power Piping and Vessels. 1998, 368: 231–237

Oka M, Ambarita H, Daimaruya M, et al. Initiation of bulges in a coke drum subjected to cyclic heating and cooling, also cyclic mechanical loads. Journal of Thermal Stresses, 2010, 33(10): 964–976

Yan Z, Zhang Y, Chen J, et al. Statistical method for the fatigue life estimation of coke drums. Engineering Failure Analysis, 2015, 48: 259–271

Penso J A, Lattarulo Y M, Seijas A J, et al. Understanding failure mechanisms to improve reliability of coke drum. In: Proceedings of ASME 1999 Pressure Vessels and Piping Conference on Operations, Applications, and Components. 1999, 395: 243–253

Xia Z, Ju F, Du Plessis P. Heat transfer and stress analysis of coke drum for a complete operating cycle. ASME Journal of Pressure Vessel Technology, 2010, 32(5): 051205

Nikic M. Optimal selection of delayed coke drum materials based on ASME Section II material property data. Thesis for the Master’s Degree. Edmonton: University of Alberta, 2013

Chen J. Experimental study of elastoplastic mechanical properties of coke drum materials. Thesis for the Master’s Degree. Edmonton: University of Alberta, 2010

Rahman H. Characterization of thermal-mechanical properties and optimal selection of coke drum materials. Thesis for the Master’s Degree. Edmonton: University of Alberta, 2015

Moss D R. Design of Vessel Supports. Pressure Vessel Design Manual: Illustrated Procedures for Solving Major Pressure Vessel Design Problems. Amsterdam: Gulf Professional Publishing, 2004, 185–296

Oka M, Ambarita H, Kawashima K, et al. Effect of hot feed injection time on thermal fatigue life of shell-to-skirt junction area of coke drums. In: Proceedings of ASME 2010 Pressure Vessels and Piping Conference. 2010, 7: 37–43

Stewart C W, Stryk A M, Presley L. Coke drum design. Petroleum Technology Quarterly. 2006. Retrieved from https://www.cbi.com/getattachment/1c85539c-2424-4b76-ba93-74445b8d6fb6/Coke-Drum-Design-Reliability-Through-Innovation.aspx, 2017–4-6

Lah R. US Patent, 7871500, 2011–01-18

Sasaki Y, Niimoto S. Study on skirt-to-shell attachment of coke drum by evaluation of fatigue strength of weld metal. In: Proceedings of ASME 2011 Pressure Vessel and Piping Conference. 2011, 3: 305–310

Sasaki Y, Niimoto S. US Patent, 8317981, 2012–11-27

Oka M, Ambarita H, Daimaruya M, et al. Study on the effects of switching temperature on the thermal fatigue life of the shell-to-skirt junction of coke drum. ASME Journal of Pressure Vessel Technology, 2011, 133(6): 061210

Cheng D H, Weil N A. The junction problem of solid-slotted cylindrical shells. ASME Journal of Applied Mechanics, 1960, 27 (2): 343–349

ASME Boiler and Pressure Vessel Code, Section II, Part D—Properties. New York: The American Society of Mechanical Engineers, 2007

ASME Boiler and Pressure Vessel Code, Section VIII, Division 2, Rules for Construction of Pressure Vessels. New York: The American Society of Mechanical Engineers, 2015

Acknowledgements

This work was supported by the Collaborative Research and Development (CRD) Grant of the National Science and Engineering Research Council (NSERC) of Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, E., Xia, Z. Optimal slot dimension for skirt support structure of coke drums. Front. Mech. Eng. 13, 554–562 (2018). https://doi.org/10.1007/s11465-018-0513-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-018-0513-y