Abstract

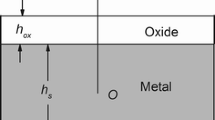

The metal materials are susceptible to be oxidized when they are exposed to the complex and harsh environments, especially at the elevated temperature. The development of corresponding chemo-mechanical coupling theory is indispensable in theoretically and numerically predicting the material properties reduction and failures due to the oxidation. In this paper, we review the historical sketch of the coupling theory of chemical reactions and mechanics in the high-temperature oxidation of metal materials. The oxidation results in the stress generation while the generated stress in turn affects the chemical reaction rate and the diffusion process of the reactants. It is therefore a complex chemo-mechanical coupling problem. This review begins with the discussion of the diffusion-controlled oxidation, and then discusses the stress-dependent diffussion during the oxidation and the oxide growth induced stress, and ends with the discussion of interaction between chemical reactions and stress. This review of chemo-mechanical coupling literature is not exhaustive; we review much of the fundamental literature and draw comparisons of coupling theory development in the filed of metal oxidation.

Similar content being viewed by others

References

Bedworth R, Pilling N. The oxidation of metals at high temperatures. J Inst Met, 1923, 29: 529–582

Young E W A. The oxygen partial pressure dependence of the defect structure of chromium(III) oxide. J Electrochem Soc, 1987, 134: 2257–2260

Atkinson A. Transport processes during the growth of oxide films at elevated temperature. Rev Mod Phys, 1985, 57: 437–470

Atkinson A, Taylor R I. The diffusion of 63Ni along grain boundaries in nickel oxide. Philos Mag A, 1981, 43: 979–998

Tsai S C, Huntz A M, Dolin C. Growth mechanism of Cr2O3 scales: Oxygen and chromium diffusion, oxidation kinetics and effect of yttrium. Mater Sci Eng-A, 1996, 212: 6–13

Rhines F N, Wolf J S. The role of oxide microstructure and growth stresses in the high-temperature scaling of nickel. Metal Trans, 1970, 1: 1701–1710

Sequeira C A C, Amaral L. Role of Kirkendall effect in diffusion processes in solids. Trans Nonferrous Met Soc China, 2014, 24: 1–11

Kofstad P. Nonstoichiometry, Electrical Conductivity and Diffusion in Binary Metal Oxides. New York: Wiley, 1972

O’Keeffe M, Moore W J. Diffusion of oxygen in single crystals of nickel oxide. J Phys Chem, 1961, 65: 1438–1439

Wagner C. Contribution to the theory of formation of oxidation films. Z Phys Chem. B, 1933, 21: 25

Tammann G. Über Anlauffarben von metallen. Z Anorg Allg Chem, 1920, 111: 78–89

Li J C M, Oriani R A, Darken L S. The thermodynamics of stressed solids. Z für Physikalische Chem, 1966, 49: 271–290

Koehler J S. Diffusion of lattice defects in a stress field. Phys Rev, 1969, 181: 1015–1019

Johnson H. Defect transport in heterogeneous stress fields. Scripta Metall, 1970, 4: 771–775

Philibert J. Diffusion and stresses. Defect Diffusion Forum, 1996, 129–130: 3–8

Aziz M J. Pressure and stress effects on diffusion in Si. Defect Diffusion Forum, 1997, 153–155: 1–10

Olmsted D L, Phillips R, Curtin W A. Modelling diffusion in crystals under high internal stress gradients. Model Simul Mater Sci Eng, 2004, 12: 781–797

Li J C M, Nolfi Jr. F V, Johnson C A. Diffusional equilibrium of substitutional atoms in a stressed solid. Acta Metall, 1971, 19: 749–752

Larché F C, Cahn J W. Overview no. 41 the interactions of composition and stress in crystalline solids. Acta Metall, 1985, 33: 331–357

Larché F, Cahn J W. A linear theory of thermochemical equilibrium of solids under stress. Acta Metall, 1973, 21: 1051–1063

Callen H B. Thermodynamics. New York: Wiley, 1960

Denton A R, Ashcroft N W. Vegard’s law. Phys Rev A, 1991, 43: 3161–3164

Larché F, Cahn J W. A nonlinear theory of thermochemical equilibrium of solids under stress. Acta Metall, 1978, 26: 53–60

Johnson W C, Schmalzried H. Phenomenological thermodynamic treatment of elastically stressed ionic crystals. J Am Ceramic Soc, 1993, 76: 1713–1719

Johnson W C. Thermodynamic equilibria in two-phase, elastically stressed ionic crystals. J Am Ceramic Soc, 1994, 77: 1581–1591

Johnson W C, Huh J Y. Thermodynamics of stress-induced interstitial redistribution in body-centered cubic metals. Metall Mat Trans A, 2003, 34: 2819–2825

Krishnamurthy R, Srolovitz D J. A general solution for two-dimensional stress distributions in thin films. J Appl Mech, 2004, 71: 691–696

Krishnamurthy R, Sheldon B W. Stresses due to oxygen potential gradients in non-stoichiometric oxides. Acta Mater, 2004, 52: 1807–1822

Dimos D, Wolfenstine J, Kohlstedt D L. Kinetic demixing and decomposition of multicomponent oxides due to a nonhydrostatic stress. Acta Metall, 1988, 36: 1543–1552

Greenberg M, Wachtel E, Lubomirsky I, et al. Elasticity of solids with a large concentration of point defects. Adv Funct Mater, 2006, 16: 48–52

Haase R. Thermodynamics of Irreversible Processes. Reading MA: Addison-Wesley, 1969

Wu C H. The role of Eshelby stress in composition-generated and stress-assisted diffusion. J Mech Phys Solids, 2001, 49: 1771–1794

Evans U R. The mechanism of oxidation and tarnishing. Trans Electrochem Soc, 1947, 91: 547–572

Stringer J. Stress generation and relief in growingoxide films. Corrosion Sci, 1970, 10: 513–543

Schütze M. Protective Oxide Scales and Their Breakdown. Chichester: John & Wiley Sons, 1997

Bradhurst D H, Heuer P M. The influence of oxide stress on the breakaway oxidation of zircaloy-2. J Nucl Mater, 1970, 37: 35–47

Ueno T. Stresses in bi-layered NiO scales. Trans JIM, 1974, 15: 167–172

Mitchell T E, Voss D A, Butler E P. The observation of stress effects during the high temperature oxidation of iron. J Mater Sci, 1982, 17: 1825–1833

Forest C, Davidson J H. Some observations on the effects of sulfur and active elements on the oxidation of Fe-Cr-Al alloys. Oxid Met, 1995, 43: 479–490

Evans H E, Huntz A M. Methods of measuring oxidation growth stresses. Mater at High Temp, 1994, 12: 111–117

Lipkin D M, Clarke D R. Measurement of the stress in oxide scales formed by oxidation of alumina-forming alloys. Oxid Met, 1996, 45: 267–280

Li M, Li T, Gao W, et al. Determination of oxide growth stress by a novel deflection method. Oxidation Met, 1999, 51: 333–351

Huntz A M. Stresses in NiO, Cr2O3 and Al2O3 oxide scales. Mater Sci Eng-A, 1995, 201: 211–228

Li M, Qian Y, Xin L. Volume ratio of an oxide to the metal (in Chinese). Corros Sci Prot Tech, 1999, 11: 284–289

Speight M V, Harris J E. The generation of stresses in oxide films growing by cation diffusion. Acta Metall, 1978, 26: 1043–1045

Evans H E. The role of oxide grain boundaries in the development of growth stresses during oxidation. Corrosion Sci, 1983, 23: 495–506

Srolovitz D J, Ramanarayanan T A. An elastic analysis of growth stresses during oxidation. Oxid Met, 1984, 22: 133–146

Tolpygo V K, Dryden J R, Clarke D R. Determination of the growth stress and strain in α-Al2O3 scales during the oxidation of Fe-22Cr-4.8Al-0.3Y alloy. Acta Mater, 1998, 46: 927–937

Tolpygo V K, Clarke D R. Competition between stress generation and relaxation during oxidation of an Fe-Cr-Al-Y alloy. Oxidation Met, 1998, 49: 187–212

Clarke D R. The lateral growth strain accompanying the formation of a thermally grown oxide. Acta Mater, 2003, 51: 1393–1407

Maharjan S, Zhang X C, Wang Z D. Analytical modeling of stress and strain of symmetrically oxidized metal. J Appl Phys, 2012, 112: 033514

Zhang Y, Zhang X, Tu S T, et al. Analytical modeling on stress assisted oxidation and its effect on creep response of metals. Oxid Met, 2014, 82: 311–330

Maharjan S, Zhang X C, Xuan F Z, et al. Residual stresses within oxide layers due to lateral growth strain and creep strain: Analytical modeling. J Appl Phys, 2011, 110: 063511

Dong X, Feng X, Hwang K C. Oxidation stress evolution and relaxation of oxide film/metal substrate system. J Appl Phys, 2012, 112: 023502

Grosseau-Poussard J L, Panicaud B, Ben Afia S. Modelling of stresses evolution in growing thermal oxides on metals. A methodology to identify the corresponding mechanical parameters. Comput Mater Sci, 2013, 71: 47–55

Panicaud B, Grosseau-Poussard J L, Dinhut J F. On the growth strain origin and stress evolution prediction during oxidation of metals. Appl Surf Sci, 2006, 252: 5700–5713

Maharjan S, Zhang X, Wang Z. Effect of oxide growth strain in residual stresses for the deflection test of single surface oxidation of alloys. Oxid Met, 2012, 77: 93–106

Dong X, Fang X, Feng X, et al. Diffusion and stress coupling effect during oxidation at high temperature. J Am Ceram Soc, 2013, 96: 44–46

Panicaud B, Grosseau-Poussard J L, Retraint D, et al. On the mechanical effects of a nanocrystallisation treatment for ZrO2 oxide films growing on a zirconium alloy. Corrosion Sci, 2013, 68: 263–274

Panicaud B, Grosseau-Poussard J L, Kemdehoundja M, et al. Mechanical features optimization for α-Cr2O3 oxide films growing on alloy NiCr30. Comp Mater Sci, 2009, 46: 42–48

Panicaud B, Grosseau-Poussard J L, Girault P, et al. Comparison of growth stress measurements with modelling in thin iron oxide films. Appl Surf Sci, 2006, 252: 8414–8420

Panicaud B, Grosseau-Poussard J L, Dinhut J F. General approach on the growth strain versus viscoplastic relaxation during oxidation of metals. Comput Mater Sci, 2008, 42: 286–294

Zhang G, Wang H, Shen S. A chemomechanical coupling model for stress analysis of oxide scale growing between ceramic coating and substrate. Acta Mech, 2017, 228: 3173–3183

Suo Y, Zhang Z, Yang X. Residual stress analysis with stress-dependent growth rate and creep deformation during oxidation. J Mater Res, 2016, 31: 2384–2391

Huntz A M, Calvarin Amiri G, Evans H E, et al. Comparison of oxidation-growth stresses in NiO film measured by deflection and calculated using creep analysis or finite-element modeling. Oxidation Met, 2002, 57: 499–521

Favergeon J, Montesin T, Bertrand G. Mechano-chemical aspects of high temperature oxidation: A mesoscopic model applied to zirconium alloys. Oxid Met, 2005, 64: 253–279

Parise M, Sicardy O, Cailletaud G. Modelling of the mechanical behavior of the metal-oxide system during Zr alloy oxidation. J Nucl Mater, 1998, 256: 35–46

Salles-Desvignes I, Montesin T, Valot C, et al. Near-coincidence lattice method for the determination of epitaxy strains during oxidation of metals. Acta Mater, 2000, 48: 1505–1515

Dong X, Fang X, Feng X, et al. Oxidation at high temperature under three-point bending considering stress-diffusion coupling effects. Oxid Met, 2016, 86: 125–133

Qi H Y, Liang X B, Li S L, et al. High-temperature oxidation behavior of DZ125 Ni-based superalloy under tensile stress. Rare Met, 2016, 13

Swaminathan N, Qu J, Sun Y. An electrochemomechanical theory of defects in ionic solids. I. Theory. Philos Mag, 2007, 87: 1705–1721

Li J C M. Chemical potential for diffusion in a stressed solid. Scripta Metall, 1981, 15: 21–28

Larcht’e F C, Cahn J. The effect of self-stress on diffusion in solids. Acta Metall, 1982, 30: 1835–1845

Larche F C, Cahn J W. The interactions of composition and stress in crystalline solids. J Res Natl Bur Stan, 1984, 89: 467–500

Sallès-Desvignes I, Bertrand G, Montesin T, et al. Coupling between diffusion, stress field and chemical reaction in a metal-gas oxidation. Solid State Phenom, 2000, 72: 9–16

Yang F, Liu B, Fang D. Modeling of growth stress gradient effect on the oxidation rate at high temperature. J Zhejiang Univ Sci A, 2010, 11: 789–793

Yue M, Dong X, Fang X, et al. Effect of interface reaction and diffusion on stress-oxidation coupling at high temperature. J Appl Phys, 2018, 123: 155301

Krishnamurthy R, Srolovitz D J. Stress distributions in growing oxide films. Acta Mater, 2003, 51: 2171–2190

Krishnamurthy R, Srolovitz D J. Stress distributions in growing polycrystalline oxide films. Acta Mater, 2004, 52: 3761–3780

Zhou H, Qu J, Cherkaoui M. Stress-oxidation interaction in selective oxidation of Cr-Fe alloys. Mech Mater, 2010, 42: 63–71

Zhou H, Qu J, Cherkaoui M. Finite element analysis of oxidation induced metal depletion at oxide-metal interface. Comput Mater Sci, 2010, 48: 842–847

Zhou H, Cherkaoui M. A finite element analysis of the reactive element effect in oxidation of chromia-forming alloys. Philos Mag, 2010, 90: 3401–3420

Loeffel K, Anand L. A chemo-thermo-mechanically coupled theory for elastic-viscoplastic deformation, diffusion, and volumetric swelling due to a chemical reaction. Int J Plast, 2011, 27: 1409–1431

Hu S, Shen S. Non-equilibrium thermodynamics and variational principles for fully coupled thermal-mechanical-chemical processes. Acta Mech, 2013, 224: 2895–2910

Craig S L. A tour of force. Nature, 2012, 487: 176–177

Liu W, Yu W, Shen S. Chemomechanical analysis for interfacial reactions between γ-TiAl alloy and glass-ceramic coating in micro/nano scale. J Am Ceram Soc, 2018, 101: 5675–5683

Yu P, Shen S. A fully coupled theory and variational principle for thermal-electrical-chemical-mechanical processes. J Appl Mech, 2014, 81: 111005

Suo Y, Shen S. General approach on chemistry and stress coupling effects during oxidation. J Appl Phys, 2013, 114: 164905

Wang H, Suo Y, Shen S. Reaction-diffusion-stress coupling effect in inelastic oxide scale during oxidation. Oxid Met, 2015, 83: 507–519

Wang H, Shen S. A chemomechanical model for stress evolution and distribution in the viscoplastic oxide scale during oxidation. J Appl Mech, 2016, 83: 051008

Chen J, Wang H, Yu P, et al. A finite element implementation of a fully coupled mechanical—Chemical theory. Int J Appl Mech, 2017, 9: 1750040

Chen J, Yu P, Wang H, et al. An ABAQUS implementation of electrochemomechanical theory for mixed ionic electronic conductors. Solid State Ion, 2018, 319: 34–45

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Yu, W. & Shen, S. Chemo-mechanical coupling effect in the high-temperature oxidation of metal materials: A review. Sci. China Technol. Sci. 62, 1246–1254 (2019). https://doi.org/10.1007/s11431-018-9500-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9500-y