Abstract

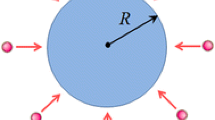

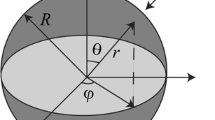

Application of silicon in high capacity electrodes of lithium ion battery suffers from stress effects and, in turn, affects voltage performance of battery. This paper established a reaction-diffusion-stress coupled model and investigated the stress induced voltage hysteresis with consideration of diffusion induced stress, surface effects and interparticle compression. It was found stress and stress induced voltage hysteresis depended on particle size. In big particles, diffusion induced stress is dominant and leads to significant hysteresis in both stress and voltage, indicating energy dissipation due to stress effects. In small particles, e.g., radius of dozens nanometers, diffusion induced stress was negligible while surface effects played dominant role, leading to nearly vanished voltage hysteresis shifting away from equilibrium potential. According to calculation, particle sizes around 100 nm are appropriate choice for electrode design as both diffusion induced stress and surface effects are insignificant. Finally, interparticle compression pushed the stress hysteresis to compressive side and led to early termination of lithiation at cut-off voltage. Denser electrode would enhance this effect. It indicated that there must be a limit of mixing ratio of silicon because higher interparticle compressive stress due to more introduced silicon would impede the battery from fully charged.

Similar content being viewed by others

References

Konishi H, Hirano T, Takamatsu D, et al. Origin of hysteresis between charge and discharge processes in lithium-rich layer-structured cathode material for lithium-ion battery. J Power Sources, 2015, 298: 144–149

Shi S Q, Gao J, Liu Y, et al. Multi-scale computation methods: Their applications in lithium-ion battery research and development. Chin Phys B, 2016, 25: 018212

Yang L, Chen H S, Jiang H, et al. Failure mechanisms of 2D silicon film anodes: In situ observations and simulations on crack evolution. Chem Commun, 2018, 54: 3997–4000

McDowell M T, Ryu I, Lee S W, et al. Studying the kinetics of crystalline silicon nanoparticle lithiation with in situ transmission electron microscopy. Adv Mater, 2012, 24: 6034–6041

Liu X H, Fan F, Yang H, et al. Self-limiting lithiation in silicon nanowires. ACS Nano, 2013, 7: 1495–1503

Gu M, Yang H, Perea D E, et al. Bending-induced symmetry breaking of lithiation in Germanium nanowires. Nano Lett, 2014, 14: 4622–4627

Kim S, Choi S J, Zhao K, et al. Electrochemically driven mechanical energy harvesting. Nat Commun, 2016, 7: 10146

Piper D M, Yersak T A, Lee S H. Effect of compressive stress on electrochemical performance of silicon anodes. J Electrochem Soc, 2013, 160: A77–A81

Sethuraman V A, Chon M J, Shimshak M, et al. In situ measurements of stress evolution in silicon thin films during electrochemical lithiation and delithiation. J Power Sources, 2010, 195: 5062–5066

Bower A F, Guduru P R, Sethuraman V A. A finite strain model of stress, diffusion, plastic flow, and electrochemical reactions in a lithium-ion half-cell. J Mech Phys Solids, 2011, 59: 804–828

Sethuraman V A, Srinivasan V, Bower A F, et al. In situ measurements of stress-potential coupling in lithiated silicon. J Electrochem Soc, 2010, 157: A1253

Lu B, Song Y, Zhang Q, et al. Voltage hysteresis of lithium ion batteries caused by mechanical stress. Phys Chem Chem Phys, 2016, 18: 4721–4727

Song Y C, Soh A K, Zhang J Q. On stress-induced voltage hysteresis in lithium ion batteries: Impacts of material property, charge rate and particle size. J Mater Sci, 2016, 51: 9902–9911

Magasinski A, Dixon P, Hertzberg B, et al. High-performance lithiumion anodes using a hierarchical bottom-up approach. Nat Mater, 2010, 9: 353–358

Rocha-Penha L, Bettiol H, Barbieri M A, et al. Author correction: Myeloperoxidase is not a good biomarker for preeclampsia prediction. Sci Rep, 2018, 8: 4396

Cheng Y T, Verbrugge M W. The influence of surface mechanics on diffusion induced stresses within spherical nanoparticles. J Appl Phys, 2008, 104: 083521

Hao F, Gao X, Fang D. Diffusion-induced stresses of electrode nanomaterials in lithium-ion battery: The effects of surface stress. J Appl Phys, 2012, 112: 103507

Sethuraman V A, Srinivasan V, Newman J. Analysis of electrochemical lithiation and delithiation kinetics in silicon. J Electrochem Soc, 2013, 160: A394–A403

Sharma P, Ganti S, Bhate N. Effect of surfaces on the size-dependent elastic state of nano-inhomogeneities. Appl Phys Lett, 2003, 82: 535–537

Luo L, Zhao P, Yang H, et al. Surface coating constraint induced self-discharging of silicon nanoparticles as anodes for lithium ion batteries. Nano Lett, 2015, 15: 7016–7022

Bucci G, Swamy T, Bishop S, et al. The effect of stress on battery-electrode capacity. J Electrochem Soc, 2017, 164: A645–A654

Roberts A P, Garboczi E J. Elastic properties of model porous ceramics. J Am Ceramic Soc, 2000, 83: 3041–3048

Yang B, He Y P, Irsa J, et al. Effects of composition-dependent modulus, finite concentration and boundary constraint on Li-ion diffusion and stresses in a bilayer Cu-coated Si nano-anode. J Power Sources, 2012, 204: 168–176

Gwak Y, Moon J, Cho M. Multi-scale analysis of an electrochemical model including coupled diffusion, stress, and nonideal solution in a silicon thin film anode. J Power Sources, 2016, 307: 856–865

Ding N, Xu J, Yao Y X, et al. Determination of the diffusion coefficient of lithium ions in nano-Si. Solid State Ion, 2009, 180: 222–225

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, C., Li, H., Song, Y. et al. On stress-induced voltage hysteresis in lithium ion batteries: Impacts of surface effects and interparticle compression. Sci. China Technol. Sci. 62, 1357–1364 (2019). https://doi.org/10.1007/s11431-018-9491-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9491-6