Abstract

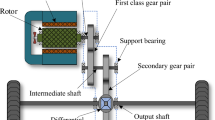

The disturbance torque generated via solar array drive assembly (SADA) can significantly degrade the key performance of satellite. The discussed SADA is composed of a two-phase hybrid stepping motor and a set of two-stage straight gear reducer. Firstly, the vibration equation of the two-phase hybrid stepping motor is established via simplifying and linearizing the electromagnetic torque. Secondly, based on the vibration equation established, the disturbance torque model of SADA is created via force analysis and force system simplification. Thirdly, for precisely ground measuring the disturbance torque aroused by SADA, a measurement system, including a strain micro-vibrations measurement platform (SMMP) and a set of gravity unloading device (GUD), is designed. Fourthly, the proposed disturbance torque model is validated by measuring and simulating the disturbance torque produced via SADA driving rigid load through GUD. The results indicate that, the proposed disturbance torque model holds the ability to describe the disturbance torque caused by SADA with high precision. Finally, the disturbance torque emitted by SADA driving a flexible load, designed to simulate solar array, is modeled and simulated via using fixed-interface mode synthesis method (FIMSM). All the conclusions drawn from this article do have a meaningful help for studying the disturbance torque produced by SADA driving solar array on orbit.

Similar content being viewed by others

References

Zhou W, Li D. Experimental research on a vibration isolation platform for momentum wheel assembly. J Sound Vibr, 2013, 332: 1157–1171

Luo Q, Li D, Zhou W, et al. Dynamic modelling and observation of micro-vibrations generated by a Single Gimbal Control Moment Gyro. J Sound Vibr, 2013, 332: 4496–4516

Zhang P F, Cheng W, Zhao Y. Measure of reaction wheels disturbance considering coupling effect (in Chinese). J Beijing Univ Aeron Astron, 2011, 37: 948–952

Zhang P F, Cheng W, Wang H, et al. Disturbance modeling and parameters identification of reaction wheel assembly on spacecraft (in Chinese). J Beijing Univ Aeron Astron, 2010, 36: 879–882

Anish N, Krishnan D, Moorthi S, et al. FPGA based microstepping scheme for stepper motor in Space-Based Solar Power Systems. In: Proceedings of the 7th IEEE International Conference on Industrial and Information Systems. Chennai, India: IEEE, 2012. 339–343

Chen J, Cheng W, Han W. Analysis and simulation of stepper motor disturbance considering structural coupling. In: Proceedings of the 2013 International Conference on Mechanical Engineering and Instrumentation. Brisbane, Australia: ICMEI, 2014. 103–108

Chen J, Cheng W, Wang Y. Modeling and simulation of solar array drive assembly disturbance driving a flexible load. In: Proceedings of the 2014 International Conference on Aerospace and Mechanical Engineering. Bangkok, Thailand: ICAME, 2014. 67–73

Yang T Y, Wang H, Xu F. Micro-stepping drive method study of twophase step motors. Micromotor Servo Tech, 2007, 40: 69–71

Zhu S Y, Xie Y, Lei Y J. Characteristic analysis of disturbance aroused by solar array tracking drive. J Natl Univ Def Technol, 2014, 36: 27–33

Woodard S E, Gell D A, Lay R R. Measured spacecraft dynamic effects on atmospheric science instruments. IEEE Trans Geosci Remote Sens, 1998, 36: 359–367

Woodard S E. Upper atmosphere research satellite in-flight dynamics study: Lessons learned. J Spacecraft Rockets, 2000, 37: 794–800

Cui G G. The satellite modeling and analysis of dynamic characteristic of drive system of solar array. Dissertation of Masteral Degree. Harbin: Engineering of Harbin Institute of Technology, 2006

Chen Y M. Application of shape memory alloys to control the vibration of solar panels. Mech Eng Autom, 2010: 173–175

Chen J P, Cheng W, Li M. Low-frequency compensation method of piezoelectric force sensor and experimental verification. J Vib Meas Diag, 2016, 36: 325–328

Xia L. The primary research on low-frequency resonate of step-motor and it’s damping methods (in Chinese). J Shenyang Univ Technol, 1994, 16: 73–78

Bodson M, Sato J S, Silver S R. Spontaneous speed reversals in stepper motors. IEEE Trans Contr Syst Technol, 2006, 14: 369–373

Yang Y, Cheng W, Wu S, et al. Experiment and simulation of electromagnetic stiffness for stepper motor. In: Proceedings of the International Conference on Applied Mechanics and Mechanical Engineering. Changsha: ICAMME, 2010. 1567–1573

Si Z H, Liu Y W, Li K. Research on modeling and driver design of solar array drive assembly. Aerosp Contrd Appl, 2010, 36: 13–19

Elsodany N M, Rezeka S F, Maharem N A. Adaptive PID control of a stepper motor driving a flexible rotor. Alexandria Eng J, 2011, 50: 127–136

Zhu S Y, Lei Y J, Wu X F. Influence analysis on dynamic characteristic parameters of solar array drive system. J Vib Eng, 2015, 28: 183–189

Kapun A, Hace A, Jezernik K. Identification of stepping motor parameters. In: Proceedings of the International Conference on Computer as a Tool. Warsaw, Poland: ICCT, 2007. 1856–1863

Acarnley P. Stepping Motors: a guide to theory and practice. 4th Ed. London, UK: The Institution of Engineering and Technology, 2007

Chen J P, Cheng W, Xia M Y. An ultra-low frequency micro-vibration testing platform based on strain-resistance effect. J Vib Shock, 2014, 33: 77–81

Gao F, Qi C K, Ren A Y, et al. Hardware-in-the-loop simulation for the contact dynamic process of flying objects in space. Sci China Tech Sci, 2016, 59: 1167–1175

Xing Y F, Li M. Engineering Vibration Foundation (in Chinese). Beijing: Beihang University Press, 2011

Hurty W C. Dynamic analysis of structural systems using component modes. AIAA J, 1965, 3: 678–685

Bampton M C C, Craig Jr R R. Coupling of substructures for dynamic analyses. AIAA J, 1968, 6: 1313–1319

Wang M, Zheng G T. An improved fixed-interface modal synthesis method. J Astrona, 2012, 33: 291–297

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Cheng, W. & Li, M. Modeling, measurement and simulation of the disturbance torque generated via solar array drive assembly. Sci. China Technol. Sci. 61, 587–603 (2018). https://doi.org/10.1007/s11431-017-9048-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-017-9048-1