Abstract

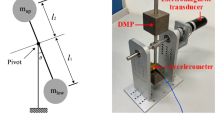

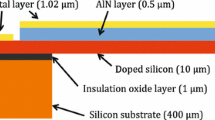

Tuned mass dampers (TMDs) are one of the most widely used devices to mitigate vibrations in structures. Usually, in conventional TMDs, viscous dampers convert the energy of vibration into heat. A new type of TMDs, called regenerative TMDs, has been developed. Energy transducers either are coupled to traditional TMDs or replace the dampers. Instead of being dissipated as heat, energy of vibration is now converted into electricity. This paper describes a regenerative TMD using piezoelectricity regenerative components as energy transducers. This piezoelectric energy-harvesting TMD (PETMD) is designed to mitigate vertical vibration as with conventional TMDs, while harvesting energy as a power resource for immediate use or storage. The system design and general design strategy of the PETMD are described, outlining the manner in which the vibration control performs its functions efficiently. The piezoelectric regenerative component is then configured and optimized by finite element analysis to maximize the power generation capacity. Finally, a small prototype is constructed to confirm the results from analysis. An energy of 80 μW was harvested from the prototype when excited by harmonic forces of about 2 N at 5 Hz and coupled to a resistor of 9.9 kΩ.

Similar content being viewed by others

References

Xiang P, Nishitani A. Seismic vibration control of building structures with multiple tuned mass damper floors integrated. Earthqu Eng Struct D, 2014, 43: 909–925

Ni T, Zuo L, Kareem A. Assessment of energy potential and vibration mitigation of regenerative tuned mass dampers on wind excited tall buildings. In: ASME 2011 International Design Engineering Technical Conferences and Computers. Volume 1: 23rd Biennial Conference on Mechanical Vibration and Noise, Parts A and B. Washington, DC, 2011. 333–342

Mak K H, Mc William S, Popov A A, et al. Performance of a cantilever piezoelectric energy harvester impacting a bump stop. J Sound Vibr, 2011, 330: 6184–6202

Dutoit N E, Wardle B L, Kim S G. Design considerations for MEMS-scale piezoelectric mechanical vibration energy harvesters. Integr Ferroelectr, 2005, 71: 121–160

Priya S, Inman D J. Energy Harvesting Technologies. New York: Springer, 2009

Erturk A, Inman D J. An experimentally validated bimorph cantilever model for piezoelectric energy harvesting from base excitations. Smart Mater Struct, 2009, 18: 025009

Rafique S, Bonello P, Shuttleworth R. Experimental validation of a novel smart electromechanical tuned mass damper beam device. J Sound Vibr, 2013, 332: 4912–4926

Tang X, Zuo L. Simulation and experiment validation of simultaneous vibration control and energy harvesting from buildings using Tuned Mass Dampers. In: Proceedings of the 2011 Congress on American Control Conference. IEEE, 2011. 3134–3139

Tang X, Zuo L. Enhanced vibration energy harvesting using dualmass systems. J Sound Vibr, 2011, 330: 5199–5209

Zhou W, Penamalli G R, Zuo L. Multi-mode vibration energy harvester and tuned mass damper using double-beam structure. In: ASME 2011 International Mechanical Engineering Congress and Exposition. Volume 7: Dynamic Systems and Control; Mechatronics and Intelligent Machines, Parts A and B. Denver, 2011. 269–276

Rafique S, Bonello P, Shuttleworth R. Experimental validation of a novel smart electromechanical tuned mass damper beam device. J Sound Vibr, 2013, 332: 4912–4926

Ouled Chtiba M, Choura S, Nayfeh A H, et al. Vibration confinement and energy harvesting in flexible structures using collocated absorbers and piezoelectric devices. J Sound Vibr, 2010, 329: 261–276

Scruggs J T. Multi-objective optimization of regenerative damping systems in vibrating structures. In: Proceedings of the 2007 Congress on American Control Conference. IEEE, 2007. 2672–2677

Harne R L. Theoretical investigations of energy harvesting efficiency from structural vibrations using piezoelectric and electromagnetic oscillators. J Acoust Soc Am, 2012, 132: 162

Sodano H A, Inman D J, Park G. A review of power harvesting from vibration using piezoelectric materials. Shock Vib Digest, 2004, 36: 197–206

Chan H L W, Unsworth J. Simple model for piezoelectric ceramics/polymer 1–3 composites used in ultrasonic transducer applications. In: IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control. IEEE, 1989, 36: 434–441

Jaffe H, Berlincourt D A. Piezoelectric transducer materials. Proc IEEE, 1965, 53: 1372–1386

Rao S S, Yap F F. Mechanical Vibrations. New York: Addison-Wesley, 1956

Lesieutre G A, Ottman G K, Hofmann H F. Damping as a result of piezoelectric energy harvesting. J Sound Vibr, 2004, 269: 991–1001

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, P., Zhang, D., Nie, X. et al. Development of piezoelectric energy-harvesting tuned mass damper. Sci. China Technol. Sci. 60, 467–478 (2017). https://doi.org/10.1007/s11431-016-0280-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-0280-5