Abstract

Purpose

This study analyses the environmental impacts referring to dairy products and to the operation of a dairy. The study aims to better understand different process stages in a dairy operation. This analysis can be used to improve the flows of energy, water, and materials in the dairy operation. The results are also used to suggest an improved allocation model for assigning the impacts of operation to single dairy products.

Methods

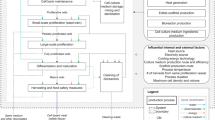

The analysis is based on a detailed, product-specific model calculation for the use of energy, water, and chemicals for more than 40 subprocesses of a dairy operation. This model has been used to elaborate the life cycle inventory for a detailed life cycle assessment study. The environmental impacts are analyzed from cradle to gate including and excluding the raw milk input. The environmental impacts are assessed with the midpoint indicators suggested by the International Reference Life Cycle Data System. Finally, results of this study are compared with an allocation model recommended for life cycle assessment (LCA) studies on milk products.

Results and discussion

The analysis of the model dairy shows that raw milk production has the main impact in all categories. Consumer packaging has the second biggest impact in many categories. The detailed dairy processing model allows the assignment of inputs and outputs for each subprocess to single dairy products and thus avoids allocation largely. The analysis of inputs to different dairy products per kilogram shows that ultra-high-temperature (UHT)-processed milk uses more chemicals for cleaning compared to the other products. Cream uses more electricity and heat compared to UHT milk and to yogurt.

Conclusions

A detailed discussion shows the overlaps and differences found for the allocation of inputs to the milk processing to final dairy products. Allocation models for different types of inputs are partly confirmed by the detailed theoretical model used for this LCA. The allocation of chemicals, steam, and electricity to single products can be improved based on the detailed dairy model developed in this study.

Similar content being viewed by others

Notes

Raw milk is separated into cream, 40% fat with a content of milk solids of 0.45 (weight per weight) and pasteurized skim milk, 0.05% fat with a content of milk solids of 0.09.

The model for operation includes water and wastewater treatment, energy, wastes, packages incl. their disposal, infrastructure, and the transport of raw milk.

For Tetra Brik, the water use stems from paper production, for the polystyrene packaging of the yogurt, the cooling water used for thermoforming has the main impact.

This is due to the allocation behind the milk powder that is conducted based on milk solid content.

Feitz, Andrew. Personal communication via e-mail on 14.4.2016.

Feitz, Andrew. Personal communication via e-mail on 14.4.2016.

References

ecoinvent Centre (2010) ecoinvent data v2.2, ecoinvent reports No. 1–25. Swiss Centre for Life Cycle Inventories, Duebendorf, Switzerland

ESU (2017) The ESU database 2017. ESU-services Ltd., Schaffhausen

European Commission, Joint Research Centre, Institute for Environment and Sustainability (2010) International reference life cycle data system (ILCD) handbook—specific guide for life cycle inventory data sets. Publication office of the European Union, Luxembourg

Feitz AJ, Lundie S, Dennien G, Morain M, Jones M (2007) Generation of an industry-specific physico-chemical allocation matrix. Application in the dairy industry and implications for system analysis. Int J LCA 12:109–117

Flysjö A, Thrane M, Hermansen JE (2014) Method to assess the carbon footprint at product level in the dairy industry. Int Dairy J 34:86–92. https://doi.org/10.1016/j.idairyj.2013.07.016

IDF (2010) A common carbon footprint approach for dairy. The IDF guide to standard lifecycle assessment methodology for the dairy sector. Bulletin of the International Dairy Federation 445/2010

IDF (2015) A common carbon footprint approach for dairy. The IDF guide to standard lifecycle assessment methodology for the dairy sector. Bulletin of the International Dairy Federation 479/2015

Jungbluth N, Keller R (2016) Milk processing—life cycle assessment of a detailed dairy model and recommendations for the allocation to single products (presentation slides). In: Holden N (ed) The 10th International Conference on Life Cycle Assessment of Food (LCA Food 2016), Dublin, Irland, 19th – 21st October 2016. University College Dublin (UCD)

Jungbluth N, Keller R, Doublet G (2014) Goal and scope definition for the life cycle assessment vol Deliverable 7.1. SUSMILK - Re-design of the dairy industry for sustainable milk processing. Project funded by the European Commission within the 7th Framework Programme. Project number n°613589. ESU-services Ltd., Zurich

Jungbluth N, Keller R, Doublet G, König A, Eggenberger S (2016a) Report on life cycle assessment, economic assessment, potential employment effects and exergy-based analysis: part I—LCA vol Deliverable 7.3. SUSMILK: Re-design of the dairy industry for sustainable milk processing. Project funded by the European Commission within the 7th Framework Programme. Project number n°613589

Jungbluth N, Keller R, König A, Eggenberger S (2016b) Life cycle inventory analysis vol Deliverable D7.2. (confidential) SUSMILK: Re-design of the dairy industry for sustainable milk processing. Project funded by the European Commission within the 7th Framework Programme. Project number n°613589. ESU-services Ltd.

Jungbluth N, Meili C, Keller R, Eggenberger S, König A, Doublet G, Flury K, Büsser S, Stucki M, Schori S, Itten R, Leuenberger M, Steiner R (2017) Life cycle inventory database on demand: EcoSpold LCI database of ESU-services. ESU-services Ltd., Schaffhausen retrieved from: www.esuservices.ch/data/data-on-demand/

Keller R, Jungbluth N, Eggenberger S (2016) Milk processing—life cycle assessment of a detailed dairy model and recommendations for the allocation to single products (paper). In: Holden N (ed) The 10th International Conference on Life Cycle Assessment of Food (LCA Food 2016), Dublin, Irland, 19th – 21st October 2016. University College Dublin (UCD)

Maga D, Font Brucart M (2016) Report on data assessment and material and energy balances vol Deliverable 1.2. SUSMILK - Re-design of the dairy industry for sustainable milk processing. Project funded by the European Commission within the 7th Framework Programme. Project number n°613589. Fraunhofer UMSICHT, Oberhausen

Maga D, Font Brucat M, Glasner C (2014) Report on dairy technology vol Deliverable 1.1. SUSMILK - Re-design of the dairy industry for sustainable milk processing. Project funded by the European Commission within the 7th Framework Programme. Project number n°613589. Fraunhofer UMSICHT, Oberhausen

Acknowledgements

The SUSMILK project is an FP7 project that is funded in the call KBBE.2013.2.5-02: “Saving water and energy for resource-efficient food processing” within the Theme 2: “Food, agriculture and fisheries, and biotechnology” of the European Union’s Seventh Framework Programme for research, technological development, and demonstration. The project started 1st November 2013 and lasts for 3 years. Twenty-one partners (7 from research and development, 4 from industry, 5 dairies, 5 for assessment and dissemination tasks; thereof 8 small and medium companies) from 9 different countries work together in SUSMILK. For further information, please visit the project website: www.susmilk.com.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Greg Thoma

Rights and permissions

About this article

Cite this article

Jungbluth, N., Keller, R. & Meili, C. Life cycle assessment of a detailed dairy processing model and recommendations for the allocation to single products. Int J Life Cycle Assess 23, 1806–1813 (2018). https://doi.org/10.1007/s11367-017-1392-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1392-x