Abstract

Purpose

The objectives of this study were to establish an allocation model for the energy consumption of pyro-metallurgical system based on the physical relationship between the input and output, apply the established model to nickel production in China and compare the difference between the allocation results derived from the established model and the traditional models.

Methods

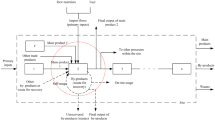

The basic methodological idea of this study is that the energy input of a multi-output pyro-metallurgical process should be allocated according to how the energy input is consumed in the process. The energy consumption of pyro-metallurgical system was decomposed into different categories (e.g. energy absorption of chemical reaction and energy loss), and these categories were classified into two groups, i.e. the categories of energy consumption dependent on the product ratio (PRDE) and the categories of energy consumption independent on the product ratio (PRIE); then, the allocation basis for each category of energy consumption was determined through the physical relationship between the energy input and metal output. The allocation for the energy consumption of nickel production in China was carried out; the system boundary includes two sub-systems (i.e. Ni–Cu coproduction system and Ni refining system), and the energy consumption of the coproduction system should be allocated; the basic data required by the allocation model and the compilation of LCI were mainly obtained from literature.

Results and discussion

The energy consumption of the processes of mining, drying, converting and floating-grinding belongs to PRIE following the principle of mass-based allocation, and the corresponding allocation factors are 64, 64, 69 and 69 %, respectively. The categories of energy consumption involved in the smelting process (the key process for demonstrating the allocation model) include both PRIE and PRDE, and the aggregated allocation factor was calculated as 56 %. The allocation result derived from the established model is lower than the results derived from the mass-based model and the market value-based model, because that, through the desulphurization reactions that occurred in the smelting process, the chemical states of copper and nickel are transformed from copper pyrite (CuFeS2) and nicopyrite ((Fe,Ni)9S8) into cuprous sulphide (Cu2S) and nickel sulphide (Ni3S2), and copper compound releases more sulphur atoms than nickel compound. When analyzing a single pyro-metallurgical process, the result of allocation is sensitive to basis selection; however, when comparing two or more pyro-metallurgical processes, the comparison result of allocation is relatively insensitive to basis selection.

Conclusions

The energy input of pyro-metallurgical system is consumed in different physical-chemical ways; the decomposition of energy consumption is significant for choosing allocation bases; the basis of mass can only be used for the allocation of PRIE, and choosing the same allocation basis for different cases without a systematic analysis will be inappropriate. The requirement of some nontraditional extra inventory data is the major limitation of the established model. This study mainly focused on how nickel production system consumes the energy input, and the energy consumption patterns of other production systems should be taken into account in future studies.

Similar content being viewed by others

References

Althaus H, Classen M (2005) Life cycle inventories of metals and methodological aspects of inventorying material resources in ecoinvent. Int J Life Cycle Assess 10(1):43–49

Chen C, Haber G, Bouzidi Y, Jullien A, Ventura A (2010) LCA allocation procedure used as an incitative method for waste recycling: an application to mineral additions in concrete. Resour Conserv Recycl 54(12):1231–1240

China Nonferrous Metals Industry Association (2013) The yearbook of nonferrous metals industry of China. Organization of the yearbook of nonferrous metals industry of China, Beijing (in Chinese)

Classen M, Althaus H, Blaser S, Scharnhorst W, Tuchschmid M, Jungbluth N, Emmenegger M (2007) Life cycle inventories of metals. Final report ecoinvent data v2.0. Swiss Centre for Life Cycle Inventories

Curran M (2007) Studying the effect on system preference by varying coproduct allocation in creating life-cycle inventory. Environ Sci Technol 41(20):7145–7151

Curran M (2008) Development of life cycle assessment methodology: a focus on co-product allocation. Erasmus University Rotterdam, Doctoral Dissertation

Domínguez A, Valero A, Valero A (2013) Exergy accounting applied to metallurgical system: the case of nickel processing. Energy 62(1):37–45

Eckelman M (2010) Facility-level energy and greenhouse gas life-cycle assessment of the global nickel industry. Resour Conserv Recycl 54(4):256–266

Feitz A, Lundie S, Dennien G, Morain M, Jones M (2007) Generation of an industry-specific physico-chemical allocation matrix-application in the dairy industry and implications for systems analysis. Int J Life Cycle Assess 12(2):109–117

Frischknecht R (2000) Allocation in life cycle inventory analysis for joint production. Int J Life Cycle Assess 5(2):85–95

General Research Institute for Nonferrous Metals (2007) The design handbook of the metallurgy of heavy nonferrous metals. Metallurgical Industry Press, Beijing

Guinée J et al (2002) Handbook on life cycle assessment: operational guide to the ISO standards. Int J Life Cycle Assess 7(5):311–313

Heijungs R, Frischknecht R (1998) A special view on the nature of the allocation problem. Int J Life Cycle Assess 3(5):321–332

ISO (2006) ISO 14044: environmental management-life cycle assessment-requirements and guidelines. The International Organization for Standardization (ISO), Geneva

Jiang J, Xu J, Hou S, Liu Y, Dai J (2005) LCA study on electrolytic nickel and copper produced by coexistence ore. Acta Sci Circumst 25(11):1570–1574

Jung J, Assen N, Bardow A (2013) An uncertainty assessment framework for LCA-based environmental process design. Comput Aided Chem Eng 32:937–942

Jung J, Assen N, Bardow A (2014) Sensitivity coefficient-based uncertainty analysis for multi-functionality in LCA. Int J Life Cycle Assess 19(3):661–676

Jungmeier G, Werner F, Jarnehammar A, Hohenthal C, Richter K (2002) Allocation in LCA of wood-based products-experiences of cost action E9. Int J Life Cycle Assess 7(5):290–294

Li Q, Guo X, Xiao S, Huang K, Zhang D (2003) Life cycle inventory analysis of CO2 and SO2 emission of imperial smelting process for Pb-Zn smelter. J Cent South Univ Technol 10(2):108–113

Li C, Chen Y, Huang X, Yu H (2012) The development of the processing technology of nickel minerals. Multi Purp Util Miner Resour 6:8–21 (in Chinese)

Lin L, Voet E, Huppes G, Udo de Haes H (2009) Allocation issues in LCA methodology: a case study of corn stover-based fuel ethanol. Int J Life Cycle Assess 14(6):529–539

Memary R, Giurco D, Mudd G, Mason L (2012) Life cycle assessment: a time-series analysis of copper. J Clean Prod 33:97–108

Ministry of Industry and Information Technology of China (2012) Methods of determination and calculation of heat balance in metallurgical furnaces for heavy non-ferrous metals (nickel flash smelting furnace)

Pelletier N, Tyedmers P (2010) Life cycle assessment of frozen tilapia fillets from Indonesian lake-based and pond-based intensive aquaculture systems. J Ind Ecol 14(3):467–481

Pelletier N, Ardente F, Brandao M, Camillis C, Pennington D (2015) Rationales for and limitations of preferred solutions for multi-functionality problems in LCA: is increased consistency possible. Int J Life Cycle Assess 20(1):74–86

Sayagh S, Ventura A, Hoang T, Francois D, Jullien A (2010) Sensitivity of the LCA allocation procedure for BFS recycled into pavement structures. Resour Conserv Recycl 54(6):348–358

Svanes E, Vold M, Hanssen O (2011) Effect of different allocation methods on LCA results of products from wild-caught fish and on the use of such results. Int J Life Cycle Assess 16(6):512–521

Swart P, Dewulf J, Biernaux A (2014) Resource demand for the production of different cathode materials for lithium ion batteries. J Clean Prod 84:391–399

Wang M, Lee H, Molburg J (2004) Allocation of energy use in petroleum refineries to petroleum products—implications for life-cycle energy use and emission inventory of petroleum transportation fuels. Int J Life Cycle Assess 9(1):34–44

Weidema B, Schmidt J (2010) Avoiding allocation in life cycle assessment revisited. J Ind Ecol 14(2):192

Xiao X, Xiao S, Guo X, Huang K, Yamamoto R (2003) LCA case study of zinc hydro and pyro-metallurgical process in China. Int J Life Cycle Assess 8(3):151–155

Ye D, Hu J (2002) Practical handbook of the thermodynamic data of inorganic compounds. Metallurgical Industry Press, Beijing (in Chinese)

Yellishetty M, Ranjith P, Tharumarajah A, Bhosale S (2009) Life cycle assessment in the minerals and metals sector: a critical review of selected issues and challenges. Int J Life Cycle Assess 14(3):257–267

Acknowledgments

This work was financially supported by the National Basic Research Program of China (973 Program, No. 2012CB720405) and the Beijing Natural Science Foundation (No. 2164056). We express our sincere appreciation to the anonymous reviewers for their valuable comments and advices.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Adisa Azapagic

Rights and permissions

About this article

Cite this article

Sun, B., Liu, Y., Nie, Z. et al. Physical parameter-based allocation for the energy consumption of pyro-metallurgical system—a case study on nickel production in China. Int J Life Cycle Assess 22, 199–212 (2017). https://doi.org/10.1007/s11367-016-1144-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-016-1144-3