Abstract

Aiming at addressing serious pollution in the No. 30106 fully mechanized coal mining face of Shiquan Coal Mine during coal cutting process, the spraying device between hydraulic supports was improved through the combination of experimental analysis, numerical simulation, and field measurement, and a novel wind-assisted centralized spraying dedusting device was developed. The newly developed device could make the formed spraying field more concentrated on the dust-producing source around the coal shearer’s drum, and thus significantly enhanced the spraying performance. According to numerical simulation results, the spraying performance reached the optimum at a hydraulic pressure of 8 MPa for the spraying device and an air pressure of 1 MPa for the pneumatic motor; under these optimal conditions, the droplet concentration in the spraying field around the coal cutter drum was as high as 24.85 g/m3, and the formed high-concentration spraying field could basically cover the whole section in the spraying field from coal wall to the support pillar. Field measured results revealed that, at a hydraulic pressure of 8 MPa and an air pressure of 1 MPa, the dust suppression rate around coal cutter driver reached up to 87.96%, suggesting that the developed wind-assisted centralized spraying dedusting device had remarkable dust suppression performance and could effectively improve the operating environment in the fully mechanized mining face.

In this paper, we have designed a novel wind-assisted centralized spraying dedusting device and studied the optimal spray parameters. Firstly, the nozzles were selected according to the multi-factor experimental platform for measuring the spraying field’s atomization characteristics. Secondly, we had a numerical simulation of the fully mechanized mining face. And the third, we tested the effect of dust removal.

Similar content being viewed by others

References

Bhaskar R (1988) Experimental studies of dust dispersion in mine airways. Min Eng 40:191–195

Cai P, Nie W, Hua Y, Wei WL, Jin H (2018) Diffusion and pollution of multi-source dusts in a fully mechanized coal face. Process Saf Environ Prot 118:93–105

Charinpanitkul T, Tanthapanichakoon W (2011) Deterministic model of open-space dust removal system using water spray nozzle: effects of polydispersity of water droplet and dust particle. Sep Purif Technol 77:382–388

Chen LJ, Li PC, Liu GM, Cheng WM, Liu ZX (2018a) Development of cement dust suppression technology during shotcrete in mine of China-A review. J Loss Prev Process Ind 55:232–242

Chen LJ, Li PC, Liu GM, Cheng WM, Liu ZX (2018b) Development of cement dust suppression technology during shotcrete in mine of China-A review. J Loss Prev Process Ind 55:232–242

Chen DW, Nie W, Cai P, Liu ZQ (2018c) The diffusion of dust in a fully-mechanized mining face with a mining height of 7 m and the application of wet dust-collecting nets. J Clean Prod 205:463–476

Cheng WM, Nie W, Zhou G, Yu YB, Ma YY, Xue J (2012) Research and practice on fluctuation water injection technology at low permeability coal seam. Saf Sci 50(4):851–856

Cheng WM, Nie W, Zhou G et al (2013) Research on eddy air-curtain dust controlled flow field in hard rock mechanized driving face. J Networks 8:453–460

Cheng WM, Yu HM, Zhou G, Nie W (2016) The diffusion and pollution mechanisms of airborne dusts in fully-mechanized excavation face at mesoscopic scale based on CFD-DEM. Process Saf Environ Prot 104:240–253

Cheng WM, Hu XM, Xie J, Zhao YY (2017) An intelligent gel designed to control the spontaneous combustion of coal: fire prevention and extinguishing properties. Fuel 210:826–835

Faschingleitner J, Höflinger W (2011) Evaluation of primary and secondary fugitive dust suppression methods using enclosed water spraying systems at bulk solids handling. Adv Powder Technol 22:236–244

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory descriptions. In: Academic Press, New York

Han FW, Wang DM, Jiang JX, Zhu X (2016) A new design of foam spray nozzle used for precise dust control in underground coal mines. Int J Min Sci Technol 26:241–246

Hu ZX, Hu XM, Cheng WM, Zhao YY, Wu MY (2018) Performance optimization of one-component polyurethane healing agent for self-healing concrete. Constr Build Mater 179:151–159

Hua Y, Nie W, Cai P, Liu YH, Peng HT, Liu Q (2018a) Pattern characterization concerning spatial and temporal evolution of dust pollution associated with two typical ventilation methods at fully mechanized excavation faces in rock tunnels. Powder Technol 334:117–131

Hua Y, Nie W, Wei WL, Liu Q, Liu YH, Peng HT (2018b) Research on multi-radial swirling flow for optimal control of dust dispersion and pollution at a fully mechanized tunnelling face. Tunn Undergr Space Technol 79:293–303

Kelager M (2006) Lagrangian fluid dynamics using smoothed particle hydrodynamics. University of Copenhagen

Konorev MM, Nesterenko GF (2012) Present-day and promising ventilation and dust-and-gas suppression systems at open pit mines. J Min Sci 48:322–328

Li XC, Hu YF, Zhang W et al (2013) Study of dust suppression by atomized water from high-pressure sprays in mines. J Cent South Univ 44:862–866

Liu XS (2007) Choose and optimization of spraying system on support for dust-laying in fully-mechanized caving face. Shandong University of Science and Technology, Shandong

Liu YH, Nie W, Jin H, Ma H, Hua Y, Cai P, Wei WL (2017a) Solidifying dust suppressant based on modified chitosan and experimental study on its dust suppression performance. Adsorpt Sci Technol 36(1-2):640–654

Liu GM, Cheng WM, Chen LJ (2017b) Investigating and optimizing the mix proportion of pumping wet-mix shotcrete with polypropylene fiber. Constr Build Mater 150:14–23

Liu YH, Nie W, Mu YB, Zhang HH, Wang HK, Jin H, Liu ZQ (2018a) A synthesis and performance evaluation of a highly efficient ecological dust. Rsc Adv 8(21):11498–11508

Liu CQ, Nie W, Bao Q, Liu Q, Wei CH, Hua Y (2018b) The effects of the pressure outlet's position on the diffusion and pollution of dust in tunnel using a shield tunneling machine. Energ Buildings 176:232–245

Liu Q, Nie W, Hua Y, Peng HT, Liu ZQ (2018c) The effects of the installation position of a multi-radial swirling air-curtain generator on dust diffusion and pollution rules in a fully-mechanized excavation face: a case study. Powder Technol 329:371–385

Luo W, Liu RH, Cui HJ et al (2013) Numerical simulation study of airflow characteristics and dust concentration on mechanized heading face. Min Eng Res 28:18–22

Ni GH, Li Z, Xie HC (2018a) The mechanism and relief method of the coal seam water blocking effect (WBE) based on the surfactants. Powder Technol 323:60–68

Ni GH, Xie HC, Li Z (2018b) Improving the permeability of coal seam with pulsating hydraulic fracturing technique: a case study in Changping coal mine, China. Process Saf Environ 117:565–572

Nie W, Cheng WM, Zhou G et al (2015a) Formation mechanism of pressure air curtain and analysis of dust suppression’s effects in mechanized excavation face. J China Coal Soc 40:609–615

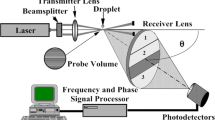

Nie W, Liu YH, Cheng WM et al (2015b) Dust removal technology of eject spraying between hydraulic supports on fully mechanized mining face. J Cent South Univ 46:4384–4390

Nie W, Ma X, Cheng WM, Liu Y, Xin L, Peng H, Wei W (2016a) A novel spraying/negative-pressure secondary dust suppression device used in fully mechanized mining face: a case study. Process Saf Environ Prot 103:126–135

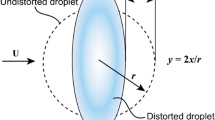

Nie W, Ma X, Liu YH et al (2016b) Experiment on the size of airflow disturbing dust removal droplet produced by high-pressure spray between supports. J China Univ Min Technol 45:670–676

Nie W, Peng HT, Jin H et al (2017a) The effect of spray pressure on atomization characteristics of external spray nozzle on coal mining machine. J China Univ Min Technol 46:41–47

Nie W, Liu YH, Wang H, Wei WL, Peng HT, Cai P, Hua Y, Jin H (2017b) The development and testing of external-spraying injection dedusting device for the heading machine in a fully-mechanized excavation face. Process Saf Environ Prot 109:716–731

Nie W, Wei WL, Ma X, Liu YH, Peng HT, Liu Q (2017c) The effects of ventilation parameters on the migration behaviors of head-on dusts in the heading face. Tunn Undergr Space Technol 70:400–408

Nie W, Wei WL, Cai P, Liu ZQ, Liu Q, Ma H, Liu HJ (2018) Simulation experiments on the controllability of dust diffusion by means of multi-radial vortex airflow. Adv Powder Technol 29(3):835–847

Prostański D (2013) Use of air-and-water spraying systems for improving dust control in mines. J Sustain Mini 12:29–34

Plumecocq W, Audouin L, Joret JP, Pretrel H (2017) Numerical method for determining water droplets size distributions of spray nozzles using a two-zone model. Nucl Eng Des 324:67–77

Poggi L A, Gaudio P, Rossi R, et al (2017) Non-invasive assessment of dust concentration and relative dustiness in a dust cloud mobilized by a controlled air inlet inside STARDUST-U facility. Reliab Eng Syst Saf 527-535

Qin YP, Zhang MM, Cui LJ et al (2011) Removal modes with the forced ventilation shunt in a fully mechanized workface. J Univ Sci Technol Beijing 33:790–794

Ren T, Wang ZW, Cooper G (2014) CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system. Tunn Undergr Space Technol 41:241–254

Serafin J, Bebcak A, Bernatik A, Lepik P, Mynarz M, Pitt M (2013) The influence of air flow on maximum explosion characteristics of dust-air mixtures. J Loss Prev Process Ind 26:209–214

Sun B, Cheng WM, Wang JY, Wang H (2018) Effects of turbulent airflow from coal cutting on pollution characteristics of coal dust in fully-mechanized mining face: a case study. J Clean Prod 201:308–324

Tessum MW, Raynor PC (2017) Effects of spray surfactant and particle charge on respirable coal dust capture. Safety and Health at Work 8:296–305

Wang XY (2008) Optimization of spray dust removal technology in fully mechanized mining face. Coal Engineering 50–52

Wang PF, Liu RH, Tang M et al (2015) Experimental study on atomization characteristics and dust suppression efficiency of high pressure spray in underground coal mine. J China Coal Soc 40:2124–2130

Wang HT, Wang DM, Tang Y, Qin B, Xin H (2014) Experimental investigation of the performance of a novel foam generator for dust suppression in underground coal mines. Adv Powder Technol 25:1053–1059

Wang QG, Wang DM, Wang HT (2016) Modeling the influence of dust-removing extraction Fan’s parameters on the dust control effects in the tunneling. Environ Manag Sustain Dev 5:18–19

Wang G, Wu MM, Wang R, Xu H, Song X (2017a) Height of the mining-induced fractured zone above a coal face. Eng Geol 216:140–152

Wang G, Li WX, Wang PF, Yang XX, Zhang ST (2017b) Deformation and gas flow characteristics of coal-like materials under triaxial stress conditions. Int J Rock Mech Min 91:72–80

Wang HT, Wang C, Wang DM (2017c) The influence of forced ventilation airflow on water spray for dust suppression on heading face in underground coal mine. Powder Technol 320:498–510

Yang CZ, Zhang YC, Ouyang ZJ et al (2012) Numerical modeling on fluid-solid coupling for the waterproof coal pillar design. J Cent South Univ 43:3704–3709

Yu HM, Cheng WM, Wu LR, Wang H, Xie Y (2017a) Mechanisms of dust diffuse pollution under forced-exhaust ventilation in fully-mechanized excavation faces by CFD-DEM. Powder Technol 317:31–47

Yu S, Yin B, Jia H, Yu J (2017b) Numerical research on micro diesel spray characteristics under ultra-high injection pressure by large Eddy simulation (LES). Int J Heat Fluid Flow 64:129–136

Yu HM, Cheng WM, Peng HT, et al (2018a) An investigation of the nozzle’s atomization dust suppression rules in a fully-mechanized excavation face based on the airflow-droplet-dust three-phase coupling model[J]. Adv Powder Technol 29(4)

Yu HM, Cheng WM, Xie Y, Peng HT (2018b) Micro-scale pollution mechanism of dust diffusion in a blasting driving face based on CFD-DEM coupled model. Environ Sci Pollut Res 25(22):21768–21788

Zhou G, Cheng WM, Chen LJ (2011) Research and practice on the key theory and Technology of Coal Mine Dust control. China Coal Industry Publishing House, Beijing

Zuo QM, Nie W, Cheng WM (2013) Research on nozzle arrangement optimization of hydraulic support in fully mechanized caving face. Ind Safe Environ Protect 39:1–3

Zhou G, Xu CC, Cheng WM, et al (2015) Effects of oxygen element and oxygen-containing functional groups on surface wettability of coal dust with various metamorphic degrees based on XPS experiment. J Anal Methods Chem

Zhou G, Zhang Q, Bai RN, Fan T, Wang G (2017) The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application. Process Saf Environ 106:117–128

Zhou G, Ma YL, Fan Y, Wang G (2018) Preparation and characteristics of a multifunctional dust suppressant with agglomeration and wettability performance used in coal mine. Chem Eng Res Des 132:729–742

Zhang JZ, Zhu TZ, Gao M, Li KK (2011) Parameter optimization and numerical simulation of dust-collecting and dedusting system with air curtain in heading face. Adv Mater Res 317-319:2073–2078

Zhang HH, Nie W, Wang HK, Bao Q, Jin H, Liu YH (2018a) Preparation and experimental dust suppression performance characterization of a novel guar gum-modification-based environmentally-friendly degradable dust suppressant. Powder Technol 339:314–325

Zhang Q, Hu XM, Wu MY, Zhao YY, Yu C (2018b) Effects of different catalysts on the structure and properties of polyurethane/water glass grouting materials. J Appl Polym Sci 135(27):46460

Funding

This work has been funded by the National Natural Science Foundation of China (NO. 51874191 and 51404147), the Focus on Research and Development Plan in Shandong Province (NO.2017GSF20111), the National Key R&D Program of China (2017YFC0805201), the China Postdoctoral Science Foundation (NO.2015M570601 and 2017T100503).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Highlights

• A novel wind-assisted centralized spraying dedusting device was designed.

• The droplet concentration distribution rules of a fully mechanized mining face were analyzed by numerical simulation.

• Field measurement showed that the spraying device achieved very good dusting effect.

Rights and permissions

About this article

Cite this article

Peng, H., Nie, W., Cai, P. et al. Development of a novel wind-assisted centralized spraying dedusting device for dust suppression in a fully mechanized mining face. Environ Sci Pollut Res 26, 3292–3307 (2019). https://doi.org/10.1007/s11356-018-3264-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3264-8