Abstract

Municipal sludge, composed of numerous types of organic matter with a gel structure, has high water content, low permeability coefficient, and poor mechanical properties. Fenton oxidation-assisted vacuum preloading method for municipal sludge treatment was proposed. First, the municipal sludge was oxidized and treated with Fenton’s reagent; then, drainage consolidation was performed on the sludge with the vacuum preloading method. The optimal dosage of Fenton’s reagent for municipal sludge was determined. Comparative experiments of the one-dimensional consolidation of municipal sludge treated with Fenton’s reagent and the drainage consolidation by Fenton oxidation-assisted vacuum preloading were conducted. The results reveal that the specific resistance of municipal sludge decreases upon Fenton oxidation by approximately 98.6% at the optimal dosage of 22%, sludge water content decreases from 82.14 to 66.67%, volume reduces by ~ 40%, and unconfined compressive strength increases to 55 kPa.

Similar content being viewed by others

Introduction

Municipal sludge is one of the biggest disposal products of urban sewage treatment (Li and Wang 2016). Previously, direct landfill disposal was used as the traditional method in China. However, this method was strictly controlled because of the shortage of arable land resources and storage capacity (Feng et al. 2013). Normally, the water content of municipal sludge treated by China’s sewage disposal plant is approximately 80–85%. If the in situ treatment can reduce the water content to 60–70%, the volume of municipal sludge can be decreased by approximately 50% (Zhou et al. 2014). This can improve the storage capacity of landfills effectively. Hence, in situ dewatering of municipal sludge is one of the most important methods for solving the abovementioned immediate problems (Lin et al. 2014).

Municipal sludge has the following three distinct characteristics (O’Kelly 2006; Thapa et al. 2009; Ruiz et al. 2010; Feng et al. 2013): (1) It contains approximately 50–70% of organic matter with a gel structure, high water content, small permeability coefficient (10−10–10−7 cm/s), and poor drainage consolidation features. (2) It has gel-like floc structures formed by extracellular polymer substances (EPSs) and microbial cells, whose EPS contains a large amount of hydrophilic substances such as protein, polysaccharide, and humic acid formed by hydroxyl and carboxyl groups. They interact with water molecules through polar bonds, which bind most of the water in the sludge and make the water discharge by the traditional vacuum preloading method difficult. (3) The organics in the municipal sludge are flexible structures, and the pores can be easily compressed under an external load. Hence, the permeability coefficient may decrease drastically and the drainage channel of the filter membranes may get clogged seriously, which then may lead to a drainage consolidation failure.

Frame filter press and vacuum preloading are two commonly used methods for municipal sludge dewatering after treatment at a sewage disposal plant. The frame filter press method cannot be used for in situ municipal sludge disposal without large-scale excavation and transportation, which causes secondary pollution. Vacuum preloading is one of the efficient technologies used for in situ dewatering of municipal sludge (Chai et al. 2005, 2013; Wu et al. 2015, 2017). However, the in situ dewatering effect is limited because of the special characteristics of municipal sludge. To overcome the drain plug and long consolidation time problems, reagents (such as Fenton’s reagent and polyacrylamide) are added to municipal sludge before the vacuum preloading treatment (Lu et al. 2001; Dewil et al. 2005; Zhu et al. 2012; Lin et al. 2014; Guezennec et al. 2015; Lee et al. 2015; Lentz 2015; Amudha et al. 2016; Ealias et al. 2016). Thus, the organic matters in the sludge can be disintegrated, more free water can be released, and the consolidation properties can be improved. Fenton’s reagent is a strong oxidant formed by the reaction of Fe2+ and H2O2 (Ribeiro et al. 2016). The hydroxyl radical produced by the reaction can cause the oxidation and recombination of the polar groups in the EPS. Fenton’s reagent can also play a role in the degradation of reduced odor substances and bleaching deodorization (Neyens and Baeyens 2003).

Hence, the effect of Fenton’s reagent on the specific resistance, consolidation characteristics, and vacuum drainage characteristics of municipal sludge had been studied. First, the optimal usage of Fenton’s reagent for municipal sludge in Shanghai, China, was analyzed. Then, the consolidation characteristics of municipal sludge with Fenton’s reagent were tested using the one-dimensional consolidation test. Finally, Fenton oxidation-assisted vacuum preloading model tests were performed on the municipal sludge. The water content, drainage rate, consolidation coefficient, unconfined compressive strength, and the existence form of bound water were examined during the test and after the test.

Materials and methods

Municipal slurry and Fenton’s reagent materials

Municipal sludge samples were obtained from a sewage disposal plant located in Shanghai, China. The particle size was measured with the Mastersizer 2000 laser particle size analyzer, as it did not require a drying process and protected the organic matter of the sludge. The results reveal that less than 5.0% of the samples have a particle size of less than 0.005 mm and approximately 42.8% of the samples have a particle size ranging from 0.005 to 0.075 mm. The properties of the municipal sludge material are presented in Table 1. The soil was classified as organic silt (OH) according to the Unified Soil Classification System (USCS).

Three reagents, namely ferrous sulfate (FeSO4), hydrogen peroxide (H2O2), and dilute sulfuric acid (H2SO4) solutions, were used for oxidizing the municipal sludge. The dosage of the reagents was determined by the mass ratio of the dry basis sludge.

Experimental methods

Vacuum filtration test

The specific resistance of the sludge is an important indicator of the sludge dewatering performance. Sludge is dehydrated relative easily with a small specific resistance value. It is divided into easy (< 5.0 × 1012 m/kg), moderate (0.5–1.0 × 1013 m/kg), and poor (> 1.0 × 1013 m/kg) grades. The values of the specific resistance can be measured using the Buchner funnel vacuum filtration test (Imc et al. 2001); a schematic representation of the device is shown in Fig. 1.

The specific resistance can be calculated as follows:

where r denotes the specific resistance of the sludge (m/kg), P represents the applied pressure (N/m2), A indicates the bottom area of the Buchner funnel (m2), b refers to the slope of the straight line in the filter equation t/v = bv + a, t denotes the filtration time (s), v indicates the filtrate volume (m3), μ represents the liquid viscosity (Pa s), and C refers to the dry weight of the filter cake, which is trapped in the filter medium, per unit volume of the filtrate (kg/m3).

The pH values, the addition of Fe2+, and the addition of H2O2 are the three main factors that affect the dewatering performance of municipal sludge (Neyens and Baeyens 2003; Neyens et al. 2004). To analyze the comprehensive influence of these three factors, the three-factor and four-level orthogonal test methods were adopted, where the pH value of the sludge was adjusted first, and then, the addition of Fe2+ and H2O2 was changed respectively. The specific resistance was used as the index to evaluate the sludge dehydration performance. Based on the orthogonal design thoughts, an L16(43) orthogonal table was used, and the influential factors are listed in Table 2.

One-dimensional consolidation test

The test equipment includes a beaker, a ring knife, a GJZ-2 middle pressure consolidation instrument, and a balance. To analyze the consolidation characteristics of the municipal sludge influenced by Fenton’s reagent, one-dimensional consolidation tests on municipal sludge were performed. According to the optimal proportion (the addition ratio of Fe2+ versus H2O2 is 1:1.75) of Fenton’s reagent added in the orthogonal test, four different dosages (0, 8, 14, and 22%) were used. The sludge conditioning method was the same as that of the specific resistance test. The reagent was first mixed with the municipal sludge and then pulled into the consolidation device. As the water content of the sludge was high, pulp could be taken with an overlarge primary load. Hence, a primary loading value of 3.125 kPa was used, and then, a multiplier was used to increase the load step by step to 400 kPa. The municipal sludge exhibited swelling because of the large amount of organics and bound water (Neyens et al. 2004). The slow drainage consolidation rate made it difficult to consolidate and stabilize the sludge in 24 h at each level load. Hence, 48 h was used as the loading time in this study.

Vacuum preloading model test

According to the optimal proportion of Fenton’s reagent added in the orthogonal test, three different dosages were used. The appending proportion of Fenton’s reagent was 8, 14, and 22% of the dry basis. A blank test (without the reagent) and a test with another reagent (FeCl3 solution) added were also conducted for the comparative analysis. Further, 4 kg of the municipal sludge and 1100 mL of the solution or water were used for all the five model tests.

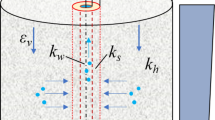

The model test apparatus consisted of a vacuum system (contains pump, pipe, and gauge, etc.), gas–liquid separation bottles, scale, model tank, sealed cover, draining layer, and drain pipe (as shown in Fig. 2). The model tank was made of a cylindrical Plexiglas barrel and a sealing cover. The height of the Plexiglas barrel was 500 mm, and the inner diameter was 180 mm. The sealing cover was a 20-mm-thick hard plate, convenient for settlement measurement. The sealing center was drilled and connected with the vacuum pump through the pipe. Both the top and the bottom of the model box were covered with geotextile and sand cushion as the draining layers. During the vacuum preloading, we ensured that the vacuum pressure in the gas–liquid separator was between 78 and 86 kPa, and pumping was stopped when the drainage rate was less than 10 mL/h for 3 h. The hydraulic discharge and the settlement were measured during the vacuum preloading. After the vacuum preloading, the water content and the unconfined compressive strength of the sludge were measured. (Nanjing Institute of Hydraulic Engineering Geotechnical Research Institute 2003; Taylor 1948).

Test results and discussion

Vacuum filtration test results

The orthogonal test plan and test results are presented in Table 3, and the variance test results are tabulated in Table 4. The results show that the significance is as follows: R(H2O2) > R(pH) > R(Fe2+). Factor C (H2O2) affects the specific resistance obviously, Factor B (Fe2+) affected the specific resistance non-obviously, and the influence of Factor A (pH) is in the middle. According to the Fenton’s reagent chemical reaction principle (Neyens 2003), the amount of H2O2 added is closely related to the amount of the strongly oxidized hydroxyl radicals generated by the chemical reaction. The larger is the number of hydroxyl radicals generated, the higher is the amount of organic matter involved in the reaction, which could release the bound water of the organics. The pH value determined the state of Fe2+ in the reaction. It could exist as Fe2+ under acidic conditions, reacting with H2O2 to form hydroxyl radicals, and the Fe3+ generated is transformed into Fe2+ to react with H2O2 to form the hydroxyl radicals again. Although the effect of Fe2+ on the chemical reaction is not significant, the amount of Fe2+ determined the number of hydroxyl radicals, which affects the oxidation effect of Fenton’s reagent on the sludge. Hence, the optimal amount of the reagent is A1B3C4 (the addition ratio of Fe2+ versus H2O2 is 1:1.75) and the specific resistance value is 2.38 × 1012 m/kg. Compared with the specific resistance of the original sludge (169.2 × 1012 m/kg), it is reduced by almost 98.6%.

To analyze the effect of the total amount of the reagent on the specific resistance of the sludge, the optimal scheme A1B3C4 was chosen and the total amount of the addition (in which the ratio of Fe2+ versus H2O2 was 1:1.75) was varied as 0, 4, 8, 14, and 22%. Figure 3 shows the relation between the specific resistance and the addition. It shows that the specific resistance of the sludge decreases with an increase in the total amount of Fenton’s reagent. The specific resistance of the sludge in the case of the addition of 22% Fenton’s reagent is only 2.29 × 1012 m/kg, accounting for 1.35% of the original sludge, i.e., 169.1 × 1012 m/kg. The sludge dewatering performance improves significantly and achieves the standard of easy dehydration. Further, the specific resistance of sludge with 10% (Lo et al. 2001) and 20% (this study) FeCl3 solution is also measured, and the specific resistance is 1.00 × 1013m/kg and 7.51 × 1012 m/kg, respectively. It is almost 2–3 times that of the sludge with Fenton’s reagent.

One-dimensional consolidation test results

The relation between the consolidation coefficient of the conditioned sludge and the load is shown in Fig. 4. The figure shows that the consolidation coefficient of the sludge gradually decreased with the increasing load, and the variation range is wide. The consolidation coefficient of the sludge with the same reagent addition is more than 10−4 cm2/s under the first stage of the load and close to 10−6 cm2/s under the last level of the load. Besides, the consolidation coefficient of the sludge increased with an increase in the reagent dosage, and the consolidation speed is accelerated. A previous one-dimensional consolidation test revealed that the consolidation coefficient of the original sludge is between 10−6 and 10−5 cm2/s (O’Kelly 2006; Feng et al. 2013). The abovementioned figure visibly indicates that the consolidation coefficient of the sludge is considerably increased by the conditioning with Fenton’s reagent. In particular, at the low load level, the consolidation coefficient is approximately 10−4–10−3 cm2/s, and the increase amplitude is about 100 times; hence, the consolidation speed is considerably accelerated.

Vacuum preloading model test results

Water discharge and drainage rate

The relation between the water discharge and the time is shown in Fig. 5. The figures show that the water discharge of the sludge samples with Fenton’s reagent (8, 14, and 22%) is greater than those of the original sludge, especially with 22 and 14% addition. The changes of the drainage rate and the vacuum pressure with time are shown in Fig. 6. It can be seen that the drainage rate is relatively quick at the beginning of the vacuum preloading time in 8–10 h. During the vacuum preloading, the drainage rate fluctuates because of the fluctuation of the vacuum pressure, but the overall trend is a decline. These results indicate that the permeability of the sludge could be improved by the addition of Fenton’s reagent. And the drainage rates are lagging behind vacuum loads, which is in line with the consolidation pore pressure dissipated law. The consolidation time is shortened, consistent with the results of the consolidation test.

Water content

Relation between water content of the sludge and the location after the test is plotted in Fig. 7. As is described in Section 2.2.3, 1100 mL of a solution or water is added for each model test. Hence, all sludge samples have a higher primary water content than the original sludge. The abovementioned figure shows that the water content of the sludge decreases upon the combination with Fenton’s reagent.

The water content close to the top and the bottom parts decreases obviously as compared to that in the middle of the sludge sample with 8% or 0 Fenton’s reagent. As a mass of pores is occupied by the bound water, with low permeability, which is difficult to discharge by vacuum preloading, the considerable amount of organic matter in the sludge easily plugged the pores and the drainage channels by deformation, and thus, the low-permeability layers in the upper and bottom sides are formed (Zhan et al. 2016), seriously affecting the drainage rate under vacuum preloading. The results also show that the final water content of the sludge conditioned with 14 and 22% Fenton’s reagent is the lowest, the average water content decreases to approximately 66.67%, and the total water content is uniform, which indicates that the number of effective pores increases after conditioning with 14 and 22% Fenton’s reagent, and a considerable amount of the bound water is transformed into free water. In general, the permeability coefficient of the sludge is increased and the pore clogging is reduced during the drainage process.

Settlement and consolidation prediction

Relation between the settlement of the sludge surface and time is plotted in Fig. 8. The variation of the sludge surface settlement is basically analogous with the water discharge. This figure shows that the compressive deformation of the sludge treated by 14 and 22% Fenton’s reagent increased significantly. The settlement values of each sludge surface (with 0, 8, 14, and 22% Fenton’s reagent) are 6.8, 18.8, 58.3, and 61.4% of the initial height of the sludge sample, respectively.

Based on the final settlement and sedimentation curves, the consolidation degree versus time plot could be obtained (as shown in Fig. 9). This plot shows that the consolidation degree of the sludge changes with the vacuum preloading time with “S”-type curves. The average consolidation degree of the sludge with 14 and 22% Fenton’s reagent reaches 80.1 and 87.4%, respectively. Combined with the results shown in Fig. 5, we find that the water content in the model with 14 and 22% Fenton’s reagent is uniform along the vertical distribution. Low-permeability layers are not formed on the top and bottom surfaces. The drainage channel is very smooth during the consolidation process, which results in a large consolidation coefficient, short consolidation time, and a high degree of consolidation at the end of the test. When no Fenton’s reagent is used in the vacuum preloading test, the permeability coefficient is low in the upper and bottom surfaces of the sludge sample because of the vacuum loading, which decreased the average consolidation coefficient of the sludge sample and prolonged the drainage consolidation time. Hence, the sludge far from the drainage boundary has a high water content and the drainage consolidation effect is poor.

According to the consolidation degree shown in Fig. 7, the average consolidation coefficient during the vacuum preloading in each model can be calculated. The average consolidation coefficient of the sludge (with 0, 8, 14, and 22% Fenton’s reagents) is 6.13 × 10−6 cm2/s, 2.34 × 10−5 cm2/s, 5.31 × 10−4 cm2/s, and 9.09 × 10−4 cm2/s, respectively. The average consolidation coefficient of the sludge increases with an increase in the usage of Fenton’s reagent. This finding indicates that the sludge permeability coefficient increases and the drainage consolidation speed is accelerated. Further, according to the calculated average consolidation coefficient, to achieve a consolidation degree of 87.4%, similar to that of the sludge with 22% Fenton’s reagent, the time required for the sludge without Fenton’s reagent is almost 2945 h.

The specific resistance of the sludge is closely related to the consolidation coefficient (Zhan et al. 2016). The consolidation coefficient is an important index reflecting the sludge consolidation rate. Sludge with a relatively small specific resistance will easily dehydrate. The relationship between the specific resistance and the average consolidation coefficient of the sludge is shown in Fig. 10. The figure shows that the consolidation coefficient decreased with an increase in the specific resistance of the sludge. This implies a deterioration of the dehydrated performance and of the consolidation behavior of the drainage.

Unconfined compressive strength

The unconfined compressive strength of the sludge after the vacuum preloading was measured under normal temperature and humidity; the results are presented in Table 5. Each sludge sample was tested twice, and the average value was considered the final result. Table 5 shows that all samples with 14 and 22% Fenton’s reagent oxidation-assisted vacuum preloading treatment had an unconfined compressive strength of more than 55 kPa, which meets the standard requirement (i.e., 50 kPa) of the municipal landfills in China (Ministry of Housing and Urban-Rural Department of the People’s Republic of China 2012). This finding also shows that the unconfined compressive strength will be improved with an increase in age, and with an increase in the usage of Fenton’s reagent.

Conclusions

The municipal sludge volume was reduced by using Fenton’s reagent oxidation-assisted vacuum preloading treatment. The specific resistance of municipal sludge was reduced by oxidation with Fenton’s reagent by approximately 98.6% at an optimal dosage of 22%. The consolidation coefficient at a low load level was 10−4–10−3 cm2/s; it increased with an increase in the addition of Fenton’s reagent. Under the vacuum preloading model test conditions, after Fenton’s reagent (concentration 14 and 22%) oxidation-assisted vacuum preloading treatment of the sludge, the water content reduced from 82.14 to 66.67%, volume reduced by approximately 40%, and unconfined compressive strength was > 55 kPa.

References

Amudha V, Kavitha S, Fernandez C et al (2016) Effect of deflocculation on the efficiency of sludge reduction by Fenton process. Environ Sci Pollut Res :1–11

Chai JC, Carter JP, Hayashi S (2005) Ground deformation induced by vacuum consolidation. J Geotech Geoenviron Eng 131:1552–1561

Chai JC, Ong CY, Carter JP et al (2013) Lateral displacement under combined vacuum pressure and embankment loading. Geotechnique 63:842–856

Dewil R, Baeyens J, Neyens E (2005) Fenton peroxidation improves the drying performance of waste activated sludge. J Hazard Mater 117:161–170

Ealias AM, Jose JV, Saravanakumar MP (2016) Biosynthesised magnetic iron nanoparticles for sludge dewatering via Fenton process. Environ Sci Pollut Res 23:1–15

Feng Y, Luo XY, Lin WA et al (2013) Geotechnical properties measurement of sewage sludge at a disposal site. Rock Soil Mech 34:115–122 (in Chinese)

Guezennec AG, Michel C, Bru K et al (2015) Transfer and degradation of polyacrylamide-based flocculants in hydrosystems: a review. Environ Sci Pollut Res Int 22:6390–6406

Imc L, Lai KC, Chen GH (2001) Salinity effect on mechanical dewatering of sludge with and without chemical conditioning. Environ Sci Technol 35:4691–4696

Lee SS, Shah HS, Awad YM, Kumar S, Ok YS (2015) Synergy effects of biochar and polyacrylamide on plants growth and soil erosion control. Environ Earth Sci 74:2463–2473

Lentz RD (2015) Polyacrylamide and biopolymer effects on flocculation, aggregate stability, and water seepage in a silt loam. Geoderma 241-242:289–294

Li F-H, Wang A-P (2016) Interaction effects of polyacrylamide application and slope gradient on potassium and nitrogen losses under simulated rainfall. Catena 136:162–174

Lin WA, Zhan XJ, Zhan TL et al (2014) Effect of FeCl3-conditioning on consolidation property of sewage sludge and vacuum preloading test with integrated PVDs at the Changan landfill, China. Geotext Geomembr 42:181–190

Lu MC, Lin CJ, Liao CH et al (2001) Influence of pH on the dewatering of activated sludge by Fenton’s reagent. Wat Sci Technol 44:327–332

Ministry of Housing and Urban-Rural Department of the People’s Republic of China (2012) The technical guidelines of sludge treatment in urban sewage treatment plant (trial). China Construction Industry Press, pp:54–65 (in Chinese)

Nanjing Institute of Hydraulic Engineering Geotechnical Research Institute (2003) Geotechnical test technology manual. People’s Transportation Press, Nanjing (in Chinese)

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98:33–50

Neyens E, Baeyens J, Dewil R, Heyder BD (2004) Advanced sludge treatment affects extracellular polymeric substances to improve activated sludge dewatering. J Hazard Mater 106:83–92

O’Kelly BC (2006) Geotechnical properties of municipal sewage sludge. Geotech Geol Eng 24:833–850

Ribeiro MC, Starling MC, Leão MM et al (2016) Textile wastewater reuse after additional treatment by Fenton’s reagent. Environ Sci Pollut Res Int 24:1–11

Ruiz T, Kaosol T, Wisniewski C (2010) Dewatering of urban residual sludges: filterability and hydro-textural characteristics of conditioned sludge. Sep Purif Technol 72:275–281

Taylor DW (1948) Fundamentals of soil mechanics. John Wiley & Sons

Thapa KB, Qi Y, Clayton SA, Hoadley AFA (2009) Lignite aided dewatering of digested sewage sludge. Water Res 43:623–634

Wu YJ, Kong GQ, Lu YT, Sun DA (2015) Ground deformation induced by vacuum loading-unloading. Environ Earth Sci 75:1–8

Wu YJ, Xu F, Yuan M, Sun DA (2017) Experimental study on vacuum preloading with flocculation for solid-liquid separation in waste slurry. Geomech Eng 13:319–331

Zhan LT, Zhang P, Zhan X, Lin W (2016) Experimental study on inhibition effect of chemical conditioning on low permeability sewage sludge layer under conditions of vacuum preloading. J Southeast Univ 46:7–13 (in Chinese)

Zhou Z, Qiao WM, Xing C et al (2014) Sludge reduction and performance analysis of a modified sludge reduction process. Water Sci Technol 69:934–940

Zhu H, Sun HY, Wang FH, Zou J, Fan JT (2012) Preparation of chitosan-based flocculant for high density waste drilling mud solid-liquid separation. J Appl Polym Sci 125(4):2646–2651

Funding

The research was financially supported by the National Natural Science Foundation of China (41772303) and Shanghai Natural Science Foundation, China (17ZR1410100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vítor Pais Vilar

Rights and permissions

About this article

Cite this article

Wu, Y., Lin, Z., Kong, G. et al. Treatment of municipal sludge by Fenton oxidation combined vacuum preloading. Environ Sci Pollut Res 25, 15990–15997 (2018). https://doi.org/10.1007/s11356-018-1736-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-1736-5