Abstract

Background

Accelerated development of advanced metals and alloys requires validated relationships between the high throughput indentation measurements and standardized tensile test protocols.

Objective

The main objective of this paper is to critically evaluate the quantitative relationships between the yield strengths measured in standard tensile tests and the indentation yield strengths obtained from the recently developed spherical indentation stress-strain protocols for a broad range of steels with varying properties and microstructures. The tensile yield strengths for the tested steels varied from 300 to 1400 MPa, providing the broadest experimental evaluation to date for the spherical indentation stress-strain protocols.

Methods

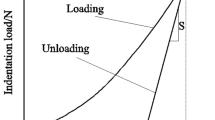

Standardized tension tests, standardized hardness measurements, and the recently developed spherical microindentation stress-strain protocols were employed on all the steels included in this study. The indentation stress-strain protocols provide a suitably normalized characterization of the material’s intrinsic mechanical response, when compared to standardized hardness measurements.

Results

It was found that the yield strengths estimated using the spherical indentation stress-strain protocols were within a 10% error. Furthermore, it was found that the tensile strengths estimated from the conventional hardness measurements exhibited higher error compared to those estimated from the spherical indentation stress-strain protocols.

Conclusions

Spherical indentation stress-strain protocols were able to predict tensile yield strengths. The role of sample thickness on the indentation measurements was specifically investigated and quantified, resulting in specific recommendation for the minimum sample size for the indentation measurements.

Similar content being viewed by others

References

Dwivedi A, Wyrobek TJ, Warren OL, Hattrick-Simpers J, Famodu OO, Takeuchi I (2008) High-throughput screening of shape memory alloy thin-film spreads using nanoindentation. J Appl Phys 104(7):073501

Gong X, Mohan S, Mendoza M, Gray A, Collins P, Kalidindi SR (2017) High throughput assays for additively manufactured Ti-Ni alloys based on compositional gradients and spherical indentation. Integrating Mater Manuf Innov 6(3):218–228

Thienhaus S, Naujoks D, Pfetzing-Micklich J, König D, Ludwig A (2014) Rapid identification of areas of interest in thin film materials libraries by combining electrical, optical, X-ray diffraction, and mechanical high-throughput measurements: a case study for the system Ni–Al. ACS Comb Sci 16(12):686–694

Khosravani A, Cecen A, Kalidindi SR (2017) Development of high throughput assays for establishing process-structure-property linkages in multiphase polycrystalline metals: application to dual-phase steels. Acta Mater 123:55–69

Meier MAR, Schubert US (2004) Combinatorial polymer research and high-throughput experimentation: powerful tools for the discovery and evaluation of new materials. J Mater Chem 14(22):3289–3299

Tsai P, Flores KM (2016) High-throughput discovery and characterization of multicomponent bulk metallic glass alloys. Acta Mater 120:426–434

Tweedie CA et al (2005) Combinatorial material mechanics: High-throughput polymer synthesis and nanomechanical screening. Adv Mat 17(21):2599

Sormana JL, Chattopadhyay S, Meredith JC (2005) High-throughput mechanical characterization of free-standing polymer films. Rev Sci Instrum 76(6):9

Hintsala ED, Hangen U, Stauffer DD (2018) High-throughput Nanoindentation for statistical and spatial property determination. Jom 70(4):494–503

Knoll H et al (2017) Combinatorial alloy design by laser additive manufacturing. Steel Res Int 88(8):11

Weaver JS, Kalidindi SR (2016) Mechanical characterization of Ti-6Al-4V titanium alloy at multiple length scales using spherical indentation stress-strain measurements. Mater Des 111:463–472

Weaver JS, Priddy MW, McDowell DL, Kalidindi SR (2016) On capturing the grain-scale elastic and plastic anisotropy of alpha-Ti with spherical nanoindentation and electron back-scattered diffraction. Acta Mater 117:23–34

Pathak S, Kalidindi SR, Mara NA (2015) Investigations of orientation and length scale effects on micromechanical responses in polycrystalline zirconium using spherical nanoindentation. SMM 113:241–245

Pathak S, Stojakovic D, Kalidindi SR (2009) Measurement of the local mechanical properties in polycrystalline samples using spherical nanoindentation and orientation imaging microscopy. Acta Mater 57(10):3020–3028

Vachhani SJ, Doherty RD, Kalidindi SR (2016) Studies of grain boundary regions in deformed polycrystalline aluminum using spherical nanoindentation. Int J Plast 81:87–101

Vachhani SJ, Kalidindi SR (2015) Grain-scale measurement of slip resistances in aluminum polycrystals using spherical nanoindentation. Acta Mater 90:27–36

Ohmura T, Tsuzaki K, Yin F (2005) Nanoindentation-induced deformation behavior in the vicinity of single grain boundary of interstitial-free steel. Mater Trans 46(9):2026–2029

Soer WA, Aifantis KE, De Hosson JTM (2005) Incipient plasticity during nanoindentation at grain boundaries in body-centered cubic metals. Acta Mater 53(17):4665–4676

Eliash T, Kazakevich M, Semenov VN, Rabkin E (2008) Nanohardness of molybdenum in the vicinity of grain boundaries and triple junctions. Acta Mater 56(19):5640–5652

Wo P, Ngan A (2004) Investigation of slip transmission behavior across grain boundaries in polycrystalline Ni 3 Al using nanoindentation. J Mater Res 19(1):189–201

Soifer YM, Verdyan A, Kazakevich M, Rabkin E (2002) Nanohardness of copper in the vicinity of grain boundaries. Scr Mater 47(12):799–804

Yang B, Vehoff H (2007) Dependence of nanohardness upon indentation size and grain size–a local examination of the interaction between dislocations and grain boundaries. Acta Mater 55(3):849–856

Pathak S, Michler J, Wasmer K, Kalidindi SR (2012) Studying grain boundary regions in polycrystalline materials using spherical nano-indentation and orientation imaging microscopy. J Mater Sci 47(2):815–823

Kalidindi SR, Mohan S, Rossi A (2017) Mechanical characterization of Mesoscale interfaces using indentation techniques. JOM 69(1):22–29

Hodzic A, Kim JK, Stachurski ZH (2001) Nano-indentation and nano-scratch of polymer/glass interfaces. II: model of interphases in water aged composite materials. Polymer 42(13):5701–5710

Kim J-K, Sham M-L, Wu J (2001) Nanoscale characterisation of interphase in silane treated glass fibre composites. Compos A: Appl Sci Manuf 32(5):607–618

Göken M, Kempf M, Bordenet M, Vehoff H (1999) Nanomechanical characterizations of metals and thin films. Surf Interface Anal 27(5–6):302–306

ASTM (2017) E384–17, standard test method for microindentation hardness of materials. ASTM International, West Conshohocken, PA www.astm.org

ASTM (2017) E92–17, standard test methods for Vickers hardness and Knoop hardness of metallic materials. ASTM International, West Conshohocken, PA www.astm.org

ASTM (2018) E10–18, standard test method for Brinell hardness of metallic materials. ASTM International, West Conshohocken, PA www.astm.org

Cahoon JR, Broughton WH, Kutzak AR (1971) The determination of yield strength from hardness measurements. Metall Trans 2(7):1979–1983

Zhang P, Li SX, Zhang ZF (2011) General relationship between strength and hardness. Mater Sci Eng A 529:62–73

Tiryakioğlu M, Robinson JS, Salazar-Guapuriche MA, Zhao YY, Eason PD (2015) Hardness–strength relationships in the aluminum alloy 7010. Mater Sci Eng A 631:196–200

Zhang HW, Subhash G, Jing XN, Kecskes LJ, Dowding RJ (2006) Evaluation of hardness–yield strength relationships for bulk metallic glasses. Philos Mag Lett 86(5):333–345

ASTM (2020) A370–20, standard test methods and definitions for mechanical testing of steel products. ASTM International, West Conshohocken, PA www.astm.org

Meyer E (1908) Contribution to the knowledge of hardness and hardness testing. Zeitschrift Des Vereines Deutscher Ingenieure 52:645–654

Tabor, D. (1951) The hardness of metals, ed. O.U. Press. N Y

Hill R et al (1947) The theory of wedge indentation of ductile materials. Proceed Royal Soc London. Series A. Math Phys Sci 188(1013):273–289

Ishlinsky, A.I., The three-dimensional plasticity problem and Brinell hardness test. J. Appl. Math. Mech. (USSR), 1944. 8(3): p. 201–244

Johnson KL (1970) The correlation of indentation experiments. J Mech Phys Solids 18(2):115–126

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Taljat B, Zacharia T, Kosel F (1998) New analytical procedure to determine stress-strain curve from spherical indentation data. Int J Solids Struct 35(33):4411–4426

Beghini M, Bertini L, Fontanari V (2006) Evaluation of the stress–strain curve of metallic materials by spherical indentation. Int J Solids Struct 43(7):2441–2459

Bhattacharya AK, Nix WD (1988) Finite element simulation of indentation experiments. Int J Solids Struct 24(9):881–891

Park YJ, Pharr GM (2004) Nanoindentation with spherical indenters: finite element studies of deformation in the elastic–plastic transition regime. Thin Solid Films 447-448:246–250

Pavlina EJ, Van Tyne CJ (2008) Correlation of yield strength and tensile strength with hardness for steels. J Mater Eng Perform 17(6):888–893

Matsuoka S (2004) Relationship between 02% proof stress and Vickers hardness of work-hardened low carbon austenitic stainless steel, 316SS. Nippon Kikai Gakkai Ronbunshu, A Hen 70(698):1535–1541

Takakuwa O, Kawaragi Y, Soyama H (2013) Estimation of the Yield Stress of Stainless Steel from the Vickers Hardness Taking Account of the Residual Stress. J Surf Eng Mater Adv Technol 03(04):7

Rudnitsky VA, Kren AP, Lantsman GA (2019) Determining yield strength of metals by microindentation with a spherical tip. Russ J Nondestruct Test 55(2):162–168

Nix WD, Gao H (1998) Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids 46(3):411–425

Fleck NA, Muller GM, Ashby MF, Hutchinson JW (1994) Strain gradient plasticity: theory and experiment. Acta Metall Mater 42(2):475–487

Demir E, Raabe D, Zaafarani N, Zaefferer S (2009) Investigation of the indentation size effect through the measurement of the geometrically necessary dislocations beneath small indents of different depths using EBSD tomography. Acta Mater 57(2):559–569

Kim J-Y, Kang SK, Greer JR, Kwon D (2008) Evaluating plastic flow properties by characterizing indentation size effect using a sharp indenter. Acta Mater 56(14):3338–3343

Budiarsa IN (2013) Indentation size effect (ISE) of Vickers hardness in steels: correlation with H/E. Appl Mech Mater 391:23–28

Farges G, Degout D (1989) Interpretation of the indentation size effect in vickers microhardness measurements-absolute hardness of materials. Thin Solid Films 181(1):365–374

Qian L, Li M, Zhou Z, Yang H, Shi X (2005) Comparison of nano-indentation hardness to microhardness. Surf Coat Technol 195(2):264–271

Ohmura T, Tsuzaki K, Matsuoka S (2001) Nanohardness measurement of high-purity Fe–C martensite. Scr Mater 45(8):889–894

Nguyen N-V, Pham T-H, Kim S-E (2018) Characterization of strain rate effects on the plastic properties of structural steel using nanoindentation. Constr Build Mater 163:305–314

Benzing JT, Poling WA, Pierce DT, Bentley J, Findley KO, Raabe D, Wittig JE (2018) Effects of strain rate on mechanical properties and deformation behavior of an austenitic Fe-25Mn-3Al-3Si TWIP-TRIP steel. Mater Sci Eng A 711:78–92

Hu Z, Lynne K, Delfanian F (2015) Characterization of materials' elasticity and yield strength through micro−/nano-indentation testing with a cylindrical flat-tip indenter. J Mater Res 30(4):578–591

Hu Z, Lynne KJ, Markondapatnaikuni SP, Delfanian F (2013) Material elastic–plastic property characterization by nanoindentation testing coupled with computer modeling. Mater Sci Eng A 587:268–282

Das G, Ghosh S, Sahay SK, Ranganath VR, Vaze KK (2004) Influence of pre-straining on mechanical properties of HSLA steel by using ball indentation technique. Z Met 95(12):1120–1127

Hamada AS, Haggag FM, Porter DA (2012) Non-destructive determination of the yield strength and flow properties of high-manganese twinning-induced plasticity steel. Mater Sci Eng A 558:766–770

Nayebi A, el Abdi R, Bartier O, Mauvoisin G (2002) New procedure to determine steel mechanical parameters from the spherical indentation technique. Mech Mater 34(4):243–254

Ma Y et al (2013) Plastic characterization of metals by combining nanoindentation test and finite element simulation. Trans Nonferrous Metals Soc China 23(8):2368–2373

Pamnani R, Karthik V, Jayakumar T, Vasudevan M, Sakthivel T (2016) Evaluation of mechanical properties across micro alloyed HSLA steel weld joints using automated ball indentation. Mater Sci Eng A 651:214–223

Ghosh S, Pal TK, Mukherjee S, Das G, Ghosh S (2008) Comparative study of heat-affected zone with weld and base material after post-weld heat treatment of HSLA steel using ball indentation technique. J Mater Sci 43(16):5474–5482

Murty KL, Miraglia PQ, Mathew MD, Shah VN, Haggag FM (1999) Characterization of gradients in mechanical properties of SA-533B steel welds using ball indentation. Int J Press Vessel Pip 76(6):361–369

Kalidindi SR, Pathak S (2008) Determination of the effective zero-point and the extraction of spherical nanoindentation stress-strain curves. Acta Mater 56(14):3523–3532

Pathak S, Shaffer J, Kalidindi S (2009) Determination of an effective zero-point and extraction of indentation stress–strain curves without the continuous stiffness measurement signal. Scr Mater 60(6):439–442

Iskakov A, Yabansu YC, Rajagopalan S, Kapustina A, Kalidindi SR (2018) Application of spherical indentation and the materials knowledge system framework to establishing microstructure-yield strength linkages from carbon steel scoops excised from high-temperature exposed components. Acta Mater 144:758–767

Weaver JS et al (2016) High throughput exploration of process- property linkages in Al-6061 using instrumented spherical microindentation and microstructurally graded samples. Integrating Mat Manuf Innov:1–20

Patel DK, Surya R (2016) Kalidindi, Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models. Acta Mater 112:295–302

Haggag, F.M., et al. (1990) The use of automated ball indentation testing to measure flow properties and estimate fracture toughness in metallic materials, in Applications of Automation Technology to Fatigue and Fracture Testing, N.A. A. Braun, and F. Smith, Editor. 1989: (West Conshohocken, PA: ASTM International), 188–208.

ISO 6892-1 (2016) Metallic materials- Tensile testing-part 1: Method of test at room temperature. p. 1–78

Pathak S, Stojakovic D, Doherty R, Kalidindi SR (2009) Importance of surface preparation on the nano-indentation stress-strain curves measured in metals. J Mater Res 24:1142–1155

Pathak S, Kalidindi SR (2015) Spherical nanoindentation stress-strain curves. Mat Sci Eng R: Reports 91:1–36

Hertz, H., Miscellaneous papers. 1896: Macmillan

Marcinkowski M, Szirmae A, FISHER R (1964) Effect of 500degreesc aging on deformation behavior of iron-chromium alloy. Trans Metallurgical Soc AIME 230(4):676

Speich G, Warlimont H (1968) Yield strength and transformation substructure of low-carbon martensite. J Iron Steel Inst 206(4):385–392

Donohue BR, Ambrus A, Kalidindi SR (2012) Critical evaluation of the indentation data analyses methods for the extraction of isotropic uniaxial mechanical properties using finite element models. Acta Mater 60(9):3943–3952

Acknowledgements

SM, NM, and SK acknowledge funding from ONR N00014-18-1-2879.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohan, S., Millan-Espitia, N., Yao, M. et al. Critical Evaluation of Spherical Indentation Stress-Strain Protocols for the Estimation of the Yield Strengths of Steels. Exp Mech 61, 641–652 (2021). https://doi.org/10.1007/s11340-021-00689-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00689-7