Abstract

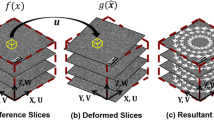

Due to challenges in generating high-quality 3D speckle patterns for Digital Volume Correlation (DVC) strain measurements, DVC experiments often utilize the intrinsic texture and contrast of composite microstructures. One common deficiency of these natural speckle patterns is their poor durability under large deformations, which can lead to decorrelation and inaccurate strain measurements. Using syntactic foams as a model material, the effects of speckle pattern degradation on the accuracy of DVC displacement and strain measurements are assessed with both experimentally-acquired and numerically-generated images. It is shown that measurement error can be classified into two regimes as a function of the percentage of markers that have disappeared from the speckle pattern. For minor levels of damage beneath a critical level of damage, displacement and strain error remained near the noise floor of less than 0.05 voxels and 100 με, respectively; above this level, error rapidly increased to unacceptable levels above 0.2 voxels and 10,000 με. This transition occurred after 30%–40% of the speckles disappeared, depending on characteristics of the speckle pattern and its degradation mechanisms. These results suggest that accurate DVC measurements can be obtained in many types of fragile materials despite severe damage to the speckle pattern.

Similar content being viewed by others

References

Sutton MA, Wolters W, Peters WH et al (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1:133–139. https://doi.org/10.1016/0262-8856(83)90064-1

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: Three-dimensional strain mapping using X-ray tomography. Exp Mech 39:217–226. https://doi.org/10.1007/BF02323555

Sutton MA, Orteu J-J, Schreier HW (2009) Image Correlation for Shape, Motion and Deformation Measurements. Springer US, Boston

Dong YL, Pan B (2017) A Review of Speckle Pattern Fabrication and Assessment for Digital Image Correlation. Exp Mech 57:1161–1181. https://doi.org/10.1007/s11340-017-0283-1

Bay BK (2008) Methods and applications of digital volume correlation. J Strain Anal Eng Des 43:745–760. https://doi.org/10.1243/03093247JSA436

Croom BP, Xu P, Lahoda EJ et al (2017) Quantifying the three-dimensional damage and stress redistribution mechanisms of braided SiC/SiC composites by in situ volumetric digital image correlation. Scr Mater 130:238–241. https://doi.org/10.1016/j.scriptamat.2016.12.021

Saucedo-Mora L, Lowe T, Zhao S et al (2016) In situ observation of mechanical damage within a SiC-SiC ceramic matrix composite. J Nucl Mater 481:13–23. https://doi.org/10.1016/j.jnucmat.2016.09.007

Saucedo-Mora L, Mostafavi M, Khoshkhou D et al (2016) Observation and simulation of indentation damage in a SiC-SiCfibre ceramic matrix composite. Finite Elem Anal Des 110:11–19. https://doi.org/10.1016/j.finel.2015.11.003

Mazars V, Caty O, Couégnat G et al (2017) Damage investigation and modeling of 3D woven ceramic matrix composites from X-ray tomography in-situ tensile tests. Acta Mater 140:130–139. https://doi.org/10.1016/j.actamat.2017.08.034

Bouterf A, Maire E, Roux S et al (2018) Analysis of compaction in brittle foam with multiscale indentation tests. Mech Mater 118:22–30. https://doi.org/10.1016/j.mechmat.2017.12.004

Barhli SM, Saucedo-Mora L, Jordan MSL et al (2017) Synchrotron X-ray characterization of crack strain fields in polygranular graphite. Carbon N Y 124:357–371. https://doi.org/10.1016/J.CARBON.2017.08.075

Hild F, Bouterf A, Roux S (2015) Damage measurements via DIC. Int J Fract 191:77–105. https://doi.org/10.1007/s10704-015-0004-7

Valle V, Bokam P, Germaneau A, Hedan S (2018) New Development of Digital Volume Correlation for the Study of Fractured Materials. Exp Mech:1–15. https://doi.org/10.1007/s11340-018-0415-2

Rannou J, Limodin N, Réthoré J et al (2010) Three dimensional experimental and numerical multiscale analysis of a fatigue crack. Comput Methods Appl Mech Eng 199:1307–1325. https://doi.org/10.1016/J.CMA.2009.09.013

Roux S, Hild F, Viot P, Bernard D (2008) Three-dimensional image correlation from X-ray computed tomography of solid foam. Compos Part A Appl Sci Manuf 39:1253–1265. https://doi.org/10.1016/j.compositesa.2007.11.011

Bouterf A, Roux S, Hild F et al (2014) Digital volume correlation applied to X-ray tomography images from spherical indentation tests on lightweight gypsum. Strain 50:444–453. https://doi.org/10.1111/str12101

Pierron F, McDonald SA, Hollis D et al (2013) Comparison of the mechanical behaviour of standard and auxetic foams by x-ray computed tomography and digital volume correlation. Strain 49:467–482. https://doi.org/10.1111/str.12053

Verhulp E, van Rietbergen B, Huiskes R (2004) A three-dimensional digital image correlation technique for strain measurements in microstructures. J Biomech 37:1313–1320. https://doi.org/10.1016/j.jbiomech.2003.12.036

Forsberg F, Siviour CR (2009) 3D deformation and strain analysis in compacted sugar using x-ray microtomography and digital volume correlation. Meas Sci Technol 20:095703. https://doi.org/10.1088/0957-0233/20/9/095703

Bornert M, Lenoir N, Bésuelle P et al (2010) Discrete and continuum analysis of localised deformation in sand using X-ray μCT and volumetric digital image correlation. Géotechnique 60:315–322. https://doi.org/10.1680/geot.2010.60.5.315

Croom BP, Jin H, Mills B et al (2019) Damage mechanisms in elastomeric foam composites: Multiscale X-ray computed tomography and finite element analyses. Compos Sci Technol 169:195–202. https://doi.org/10.1016/j.compscitech.2018.11.025

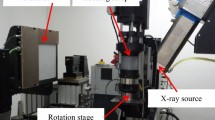

Croom B, Wang W-M, Li J, Li X (2016) Unveiling 3D Deformations in Polymer Composites by Coupled Micro X-Ray Computed Tomography and Volumetric Digital Image Correlation. Exp Mech 56:999–1016. https://doi.org/10.1007/s11340-016-0140-7

Patterson BM, Escobedo-Diaz JP, Dennis-Koller D, Cerreta E (2012) Dimensional quantification of embedded voids or objects in three dimensions using X-ray tomography. Microsc Microanal 18:390–398. https://doi.org/10.1017/S1431927611012554

Patterson BM, Cordes NL, Henderson K et al (2016) In situ X-ray synchrotron tomographic imaging during the compression of hyper-elastic polymeric materials. J Mater Sci 51:171–187. https://doi.org/10.1007/s10853-015-9355-8

Gupta N, Kishore WE, Sankaran S (2001) Studies on compressive failure features in syntactic foam material. J Mater Sci 36:4485–4491. https://doi.org/10.1023/A:1017986820603

Yu M, Zhu P, Ma Y (2013) Effects of particle clustering on the tensile properties and failure mechanisms of hollow spheres filled syntactic foams: A numerical investigation by microstructure based modeling. Mater Des 47:80–89. https://doi.org/10.1016/j.matdes.2012.12.004

Croom BP, Jin H, Carroll J et al (2018) Particle clustering effects on damage mechanisms in syntactic foams. Submitted

Adrien J, Maire E, Gimenez N, Sauvant-Moynot V (2007) Experimental study of the compression behaviour of syntactic foams by in situ X-ray tomography. Acta Mater 55:1667–1679. https://doi.org/10.1016/j.actamat.2006.10.027

Limodin N, Réthoré J, Adrien J et al (2011) Analysis and Artifact Correction for Volume Correlation Measurements Using Tomographic Images from a Laboratory X-ray Source. Exp Mech 51:959–970. https://doi.org/10.1007/s11340-010-9397-4

Mazzoleni P, Matta F, Zappa E et al (2015) Gaussian pre-filtering for uncertainty minimization in digital image correlation using numerically-designed speckle patterns. Opt Lasers Eng 66:19–33. https://doi.org/10.1016/j.optlaseng.2014.08.004

Lachambre J, Maire E, Adrien J, Choqueuse D (2013) In situ observation of syntactic foams under hydrostatic pressure using X-ray tomography. Acta Mater 61:4035–4043. https://doi.org/10.1016/j.actamat.2013.03.017

Gupta N (2007) A functionally graded syntactic foam material for high energy absorption under compression. Mater Lett 61:979–982. https://doi.org/10.1016/j.matlet.2006.06.033

Pan B, Xie H, Wang Z et al (2008) Study on subset size selection in digital image correlation for speckle patterns. Opt Express 16:7037. https://doi.org/10.1364/OE.16.007037

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20:062001. https://doi.org/10.1088/0957-0233/20/6/062001

Landauer AK, Patel M, Henann DL, Franck C (2018) A q-Factor-Based Digital Image Correlation Algorithm (qDIC) for Resolving Finite Deformations with Degenerate Speckle Patterns. Exp Mech 58:815–830. https://doi.org/10.1007/s11340-018-0377-4

Pan B, Dafang W, Yong X (2012) Incremental calculation for large deformation measurement using reliability-guided digital image correlation. Opt Lasers Eng 50:586–592. https://doi.org/10.1016/j.optlaseng.2011.05.005

Hu Z, Luo H, Bardenhagen SG et al (2015) Internal Deformation Measurement of Polymer Bonded Sugar in Compression by Digital Volume Correlation of In-situ Tomography. Exp Mech 55:289–300. https://doi.org/10.1007/s11340-014-9856-4

Tagliavia G, Porfiri M, Gupta N (2011) Analysis of particle-to-particle elastic interactions in syntactic foams. Mech Mater 43:952–968. https://doi.org/10.1016/j.mechmat.2011.08.008

Acknowledgements

This research is supported by Sandia National Laboratories and the National Science Foundation (NSF) Graduate Research Fellowship Program (DGE-1842490). Sandia National Laboratories is a multimission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC., a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA-0003525. This paper describes objective technical results and analysis. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the U.S. Department of Energy or the United States Government.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Croom, B., Jin, H., Mills, B. et al. Effect of Fragile Speckle Patterns on Accuracy of Digital Volume Correlation. Exp Mech 59, 991–1005 (2019). https://doi.org/10.1007/s11340-019-00512-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00512-4