Abstract

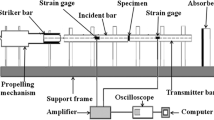

Limited methods exist for the characterization of interfacial properties in fiber reinforced composites under dynamic loading conditions since conventional techniques are designed for the measurement of a composite’s bulk properties rather than that of the fiber-matrix interface. Here, a novel experimental method is reported for the measurement of interfacial strength across various loading rates using a single fiber. The experimental apparatus uses a single fiber pullout approach along with a piezoelectric stack actuator to enable a single fixture to generate a wide range of controlled loading rates. The voltage-strain relationship is measured and the applied strain rate is controlled using resistors with varying magnitudes within a properly designed discharge circuit. The piezoelectric actuator is protected against backflow current surges using a silicon controlled rectifier, and against parasitic inductance through a toggle switch. It is shown that the proposed method accommodates single fiber specimens while providing similar performance to a Split-Hopkinson bar by reaching strain rates of up to 104 s−1, however with greater flexibility of loading rate. Single aramid fibers are tested at various strain rates and show expected interfacial shear strength independent of the embedded fiber length. The results indicate the potential of the proposed experimental method as a simple and fast technique to measure the fiber matrix interfacial properties through direct pullout at high strain rates.

Similar content being viewed by others

References

Chawla KK (2012) Composite materials: science and engineering. Springer, New York

Hao Y, Hao H (2013) Dynamic compressive behaviour of spiral steel fibre reinforced concrete in split Hopkinson pressure bar tests. Constr Build Mater 48:521–532. https://doi.org/10.1016/J.CONBUILDMAT.2013.07.022

Gay D, Hoa S, Tsai S (2002) Composite materials. CRC Press, Boca Raton

Gibson RF (2016) Principles of composite material mechanics. CRC Press, Boca Raton

Malakooti MH, Hwang H-S, Goulbourne NC, Sodano HA (2017) Role of ZnO nanowire arrays on the impact response of aramid fabrics. Compos Part B Eng 127:222–231. https://doi.org/10.1016/J.COMPOSITESB.2017.05.084

Bhatnagar A (2016) Lightweight ballistic composites: military and law-enforcement. Woodhead Publishing, Sawston

Sockalingam S, Chowdhury SC, Gillespie JW, Keefe M (2017) Recent advances in modeling and experiments of Kevlar ballistic fibrils, fibers, yarns and flexible woven textile fabrics – a review. Text Res J 87:984–1010. https://doi.org/10.1177/0040517516646039

Tam T, Bhatnagar A (2016) High-performance ballistic fibers and tapes. Light Ballist Compos:1–39. https://doi.org/10.1016/B978-0-08-100406-7.00001-5

Qin J, Zhang G, Zhou L et al (2017) Dynamic/quasi-static stab-resistance and mechanical properties of soft body armour composites constructed from Kevlar fabrics and shear thickening fluids. RSC Adv 7:39803–39813. https://doi.org/10.1039/C7RA07549A

Kim J-K, Mai YW (1998) Engineered interfaces in fiber reinforced composites. Elsevier Sciences, Amsterdam

Struszczyk M, Puszkarz A, Wilbik-Hałgas B et al (2014) The surface modification of ballistic textiles using plasma-assisted chemical vapor deposition (PACVD). Text Res J 84:2085–2093. https://doi.org/10.1177/0040517514528559

Li S, Han K, Rong H et al (2014) Surface modification of aramid fibers via ammonia-plasma treatment. J Appl Polym Sci 131. https://doi.org/10.1002/app.40250

Wang J, Chen P, Xiong X, et al (2017) Interface characteristic of aramid fiber reinforced poly(phthalazinone ether sulfone ketone) composite. https://doi.org/10.1002/sia.6224

Tehrani M, Boroujeni AY, Hartman TB et al (2013) Mechanical characterization and impact damage assessment of a woven carbon fiber reinforced carbon nanotube–epoxy composite. Compos Sci Technol 75:42–48. https://doi.org/10.1016/J.COMPSCITECH.2012.12.005

Hymas C, Lacey S, Rohrbach K, et al (2014) Novel PBA-grafted carbon nanotube soft body armor

Kolsky H (1949) An Investigation of the Mechanical Properties of Materials at very High Rates of Loading. Proc Phys Soc Sect B 62:676–700. https://doi.org/10.1088/0370-1301/62/11/302

Owens AT (2007) Development of a split hopkinson tension bar for testing stress-strain response of particulate composites under high rates of loading. Auburn University, Auburn

Kaiser MA, Wilson L, Saunders W (1998) Advancements in the Split Hopkinson Bar Test. Virginia Polytechnic Institute and State University, Blacksburg

Chen WW, Song B (2011) Split Hopkinson (Kolsky) bar : design, testing and applications. Springer, New York

Hosur M, Alexander J, Vaidya U, Jeelani S (2001) High strain rate compression response of carbon/epoxy laminate composites. Compos Struct 52:405–417. https://doi.org/10.1016/S0263-8223(01)00031-9

Caverzan A, Cadoni E, di Prisco M (2012) Tensile behaviour of high performance fibre-reinforced cementitious composites at high strain rates. Int J Impact Eng 45:28–38. https://doi.org/10.1016/J.IJIMPENG.2012.01.006

Zhu D, Mobasher B, Erni J et al (2012) Strain rate and gage length effects on tensile behavior of Kevlar 49 single yarn. Compos Part A Appl Sci Manuf 43:2021–2029. https://doi.org/10.1016/J.COMPOSITESA.2012.06.007

joo KD, El-Tawil S, Naaman AE (2009) Rate-dependent tensile behavior of high performance fiber reinforced cementitious composites. Mater Struct 42:399–414. https://doi.org/10.1617/s11527-008-9390-x

Herrera-Franco PJ, Drzal LT (1992) Comparison of methods for the measurement of fibre/matrix adhesion in composites. Composites 23:2–27. https://doi.org/10.1016/0010-4361(92)90282-Y

Piggott MR (1997) Why interface testing by single-fibre methods can be misleading. Compos Sci Technol 57:965–974. https://doi.org/10.1016/S0266-3538(97)00036-5

Mahmoud MA, Elafandy TH, Okail HO, Abdelrahman AA (2014) Interfacial shear behavior of composite flanged concrete beams. HBRC J 10:206–214. https://doi.org/10.1016/J.HBRCJ.2013.11.001

Kolitawong C (2011) High strain rate behavior of steel cord rubber composite for pneumatic tyre. In: 12th Japanese-European Symposium on Composite Materials. JSCM

Kerans RJ, Parthasarathy TA (1991) Theoretical Analysis of the Fiber Pullout and Pushout Tests. J Am Ceram Soc 74:1585–1596. https://doi.org/10.1111/j.1151-2916.1991.tb07144.x

Ehlert GJ, Sodano HA (2009) Zinc Oxide Nanowire Interphase for Enhanced Interfacial Strength in Lightweight Polymer Fiber Composites. ACS Appl Mater Interfaces 1:1827–1833. https://doi.org/10.1021/am900376t

Hodzic A, Stachurski ZH, kim JK (2001) An analysis of microdroplet test: Effects of specimen geometry, matrix type, fibre treatment and water ageing. Polym Polym Compos 9:499–508

Hodzic A, Kalyanasundaram S, Lowe A, Stachurski ZH (1998) The microdroplet test: experimental and finite element analysis of the dependance of failure mode on droplet shape. Compos Interfaces 6:375–389. https://doi.org/10.1163/156855498X00379

Kang S-K, Lee D-B, Choi N-S (2009) Fiber/epoxy interfacial shear strength measured by the microdroplet test. Compos Sci Technol 69:245–251. https://doi.org/10.1016/J.COMPSCITECH.2008.10.016

Patterson BA, Sodano HA (2016) Enhanced Interfacial Strength and UV Shielding of Aramid Fiber Composites through ZnO Nanoparticle Sizing. ACS Appl Mater Interfaces 8:33963–33971. https://doi.org/10.1021/acsami.6b07555

ten Busschen A, Selvadurai APS (1995) Mechanics of the Segmentation of an Embedded Fiber, Part I: Experimental Investigations. J Appl Mech 62:87. https://doi.org/10.1115/1.2895888

Gong XJ, Arthur JA, Penn LS (2001) Strain rate effect in the single-fiber-fragmentation test. Polym Compos 22:349–360. https://doi.org/10.1002/pc.10543

Ehlert GJ (2012) Development of a Zinc oxide nanowire interphase for enhanced structural composites. University of Florida, Gainesville

Li Z, Bi X, Lambros J, Geubelle PH (2002) Dynamic fiber debonding and frictional push-out in mode composite systems: Experimental observations. Exp Mech 42:417–425. https://doi.org/10.1007/BF02412147

DiFrancia C, Ward TC, Claus RO (1996) The single-fibre pull-out test. 1: Review and interpretation. Compos Part A Appl Sci Manuf 27:597–612. https://doi.org/10.1016/1359-835X(95)00069-E

Piggott MR (2012) Composite Interfaces The single-fibre pull-out method: its advantages, interpretation and experimental realization. Compos Interfaces 1:211–223. https://doi.org/10.1163/156855493X00086

Kelly A, Tyson WR (1965) Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J Mech Phys Solids 13:329–350. https://doi.org/10.1016/0022-5096(65)90035-9

Sørensen BF, Lilholt H (2016) Fiber pull-out test and single fiber fragmentation test - analysis and modelling. IOP Conf Ser Mater Sci Eng 139:012009. https://doi.org/10.1088/1757-899X/139/1/012009

Nasser J, Lin J, Sodano H (2018) High strength fiber reinforced composites with surface fibrilized aramid fibers. J Appl Phys 124:045305. https://doi.org/10.1063/1.5026987

Nasser J, Lin J, Steinke K, Sodano HA (2019) Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings. Compos Sci Technol 174:125–133. https://doi.org/10.1016/J.COMPSCITECH.2019.02.025

Patterson BA, Malakooti MH, Lin J et al (2018) Aramid nanofibers for multiscale fiber reinforcement of polymer composites. Compos Sci Technol 161:92–99. https://doi.org/10.1016/J.COMPSCITECH.2018.04.005

Malakooti MH, Patterson BA, Hwang H-S, Sodano HA (2016) Development of multifunctional fiber reinforced polymer composites through ZnO nanowire arrays. In: Goulbourne NC (ed). International Society for Optics and Photonics, p 98000L

Shannag MJ, Brincker R, Hansen W (1997) Pullout behavior of steel fibers from cement-based composites. Cem Concr Res 27:925–936. https://doi.org/10.1016/S0008-8846(97)00061-6

Davies IJ, Ogasawara T, Ishikawa T (2005) Distribution of fibre pullout length and interface shear strength within a single fibre bundle for an orthogonal 3-D woven Si-Ti-C-O fibre/Si-Ti-C-O matrix composite tested at 1100 • C in air. J Eur Ceram Soc 25:599–604. https://doi.org/10.1016/j.jeurceramsoc.2004.03.022

Pompo A, Stupak PR, Nicolais L, Marchese B (1996) Analysis of steel fibre pull-out from a cement matrix using video photography. Cem Concr Compos 18:3–8. https://doi.org/10.1016/0958-9465(95)00034-8

Mäder E, Gao S-L, Plonka R (2006) Static and dynamic properties of single and multi-fiber/epoxy composites modified by sizings. https://doi.org/10.1016/j.compscitech.2006.05.020

Mäder E, Grundke K, Jacobasch H-J, Wachinger G (1994) Surface, interphase and composite property relations in fibre-reinforced polymers. Composites 25:739–744. https://doi.org/10.1016/0010-4361(94)90209-7

Vijaya MS (2013) Piezoelectric materials and devices: applications in engineering and medical sciences. CRC Press, Boca Raton

Natori K (1994) Ballistic metal-oxide-semiconductor field effect transistor. J Appl Phys 76:4879–4890. https://doi.org/10.1063/1.357263

The Silicon-Controlled Rectifier (SCR) | Thyristors | Electronics Textbook. https://www.allaboutcircuits.com/textbook/semiconductors/chpt-7/silicon-controlled-rectifier-scr/. Accessed 28 Dec 2017

Chang C, Alves F, Karunasiri G (2016) Understanding of self-terminating pulse generation using silicon controlled rectifier and RC load. AIP Adv 6:015209. https://doi.org/10.1063/1.4940305

Zhang P, Wang Y, Zhang X et al (2014) Novel silicon-controlled rectifier (SCR) for digital and high-voltage ESD power supply clamp. SCIENCE CHINA Inf Sci 57:1–6. https://doi.org/10.1007/s11432-013-5016-1

Sayed H, Zurfi A, Zhang J (2017) Investigation of the effects of load parasitic inductance on SiC MOSFETs switching performance. In: 2017 IEEE International Conference on Industrial Technology (ICIT). IEEE, pp 125–129

Umetani K, Yagyu K, Hiraki E (2016) A design guideline of parasitic inductance for preventing oscillatory false triggering of fast switching GaN-FET. IEEJ Trans Electr Electron Eng 11:S84–S90. https://doi.org/10.1002/tee.22339

Cheng M, Chen W, Weerasooriya T (2005) Mechanical Properties of Kevlar® KM2 Single Fiber. J Eng Mater Technol 127:197. https://doi.org/10.1115/1.1857937

Chua PS, Piggott MR (1985) The glass fibre—polymer interface: I—theoretical consideration for single fibre pull-out tests. Compos Sci Technol 22:33–42. https://doi.org/10.1016/0266-3538(85)90089-2

Mack O (2006) XVIII IMEKO world congress Metrology for a Sustainable Development a new calibration method with static loads for piezoelectric force transducers. Rio de Janeiro

Crosswy FL, Kalb HT (1968) Archive copy do not loan t performance of a dynamically compensated load cell force measurement system. Tennesse

Goldberg RK, Roberts GD (2005) Strain Rate Sensitivity of Epoxy Resin in Tensile and Shear Loading

Siviour CR, Jordan JL High Strain Rate Mechanics of Polymers: A Review. 10.1007/s40870-016-0052-8

Giannopoulos IP, Burgoyne CJ (2009) Viscoelasticity of Kevlar 49 fibres. In: 16th National Conference on Concrete Structure

Ou Y, Zhu D, Huang M, Li H (2017) The effects of gage length and strain rate on tensile behavior of Kevlar® 29 single filament and yarn. J Compos Mater 51:109–123. https://doi.org/10.1177/0021998316639121

Sanborn BD, Weerasooriya TT (2013) Effect of Strain Rates and Pre-Twist on Tensile Strength of Kevlar KM2 Single Fiber. Report ARL-TR-6403, Army Research Laboratory, USA

Acknowledgements

The authors gratefully acknowledge financial support for this research from the Army Research Office (Contract #W911NF1610229).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hwang, H.S., Nasser, J. & Sodano, H.A. Piezoelectric Stack Actuator for Measurement of Interfacial Shear Strength at High Strain Rates. Exp Mech 59, 979–990 (2019). https://doi.org/10.1007/s11340-019-00502-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00502-6