Abstract

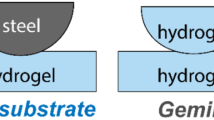

Hydrogel substrates with a stiffness gradient have been used as a surrogate of the extracellular matrix (ECM) to investigate how cells respond to the stiffness of their surrounding matrix. Various fabrication methods have been proposed to create a stiffness gradient in the hydrogel substrate, and some of them rely on generating a concentration gradient in a prepolymer solution before photo-polymerization. One easy way to do so is to coalesce two prepolymer solution drops of different stiffness values in a narrow confinement formed by two glass surfaces and then to induce polymerization using ultraviolet (UV) light irradiation, as proposed by Lo et al. [Biophys. J. 2000, 79:144–152]. We have improved their method to enable modulating the obtained stiffness gradient and characterized fabricated polyacrylamide (PAAM) gels. We controlled the coalescence and mixing duration of two prepolymer drops using the lab-built Hele-Shaw cell device and glass surfaces with a superhydrophobic barrier. Limited mixing between the drops created a concentration gradient of the gel ingredient, which was converted to a stiffness gradient by UV-based photo-polymerization. Atomic force microscopy (AFM) indentation showed that the fabricated gels had the stiffness gradient zone at the center and that the width of the zone increased with the mixing duration.

Similar content being viewed by others

References

Discher DE, Janmey P, Wang Y-L (2005) Tissue cells feel and respond to the stiffness of their substrate. Science 310:1139–1143

Watt FM, Huck WTS (2013) Role of the extracellular matrix in regulating stem cell fate. Nat Rev Mol Cell Biol 14:467–473

Charras G, Sahai E (2014) Physical influences of the extracellular environment on cell migration. Nat Rev Mol Cell Biol 15:813–824

Janson IA, Putnam AJ (2014) Extracellular matrix elasticity and topography: material-based cues that affect cell function via conserved mechanisms. J Biomed Mater Res A 103:1248–1258

Levental I, Georges PC, Janmey PA (2007) Soft biological materials and their impact on cell function. Soft Matt 3:299–306

Trappmann B, Chen CS (2013) How cells sense extracellular matrix stiffness: a material's perspective. Curr Op Biotechnol 24:948–953

Wen JH, Vincent LG, Fuhrmann A, Choi YS, Hribar KC, Taylor-Weiner H, Chen S, Engler AJ (2014) Interplay of matrix stiffness and protein tethering in stem cell differentiation. Nat Mater 13:979–987

Engler AJ, Sen S, Sweeney HL, Discher DE (2006) Matrix elasticity directs stem cell lineage specification. Cell 126:677–689

Yeung T, Georges PC, Flanagan LA, Marg B, Ortiz M, Funaki M, Zahir N, Ming W, Weaver V, Janmey PA (2005) Effects of substrate stiffness on cell morphology, cytoskeletal structure, and adhesion. Cell Motil Cytoskel 60:24–34

Chen L, Zhang Z, Qiu J, Zhang L, Luo X, Jang J (2014) Chaperonin CCT-mediated AIB1 folding promotes the growth of ERα-positive breast cancer cells on hard substrates. PLoS One 9:e96085

Whang M, Kim J (2016) Synthetic hydrogels with stiffness gradients for durotaxis study and tissue engineering scaffolds. Tissue Eng Regen Med 13:126–139

Burdick JA, Khademhosseini A, Langer R (2004) Fabrication of gradient hydrogels using a microfluidics/photopolymerization process. Langmuir 20:5153–5156

Zaari N, Rajagopalan P, Kim SK, Engler AJ, Wong JY (2004) Photopolymerization in microfluidic gradient generators: microscale control of substrate compliance to manipulate cell response. Adv Mater 16:2133–2137

Sundararaghavan HG, Monteiro GA, Firestein BL, Shreiber DI (2009) Neurite growth in 3D collagen gels with gradients of mechanical properties. Biotechnol Bioeng 102:632–643

Byfield FJ, Wen Q, Levental I, Nordstrom K, Arratia PE, Miller RT, Janmey PA (2009) Absence of filamin a prevents cells from responding to stiffness gradients on gels coated with collagen but not fibronectin. Biophys J 96:5095–5102

Isenberg BC, DiMilla PA, Walker M, Kim S, Wong JY (2009) Vascular smooth muscle cell durotaxis depends on substrate stiffness graident strength. Biophys J 97:1313–1322

Orsi G, Fagnano M, De Maria C, Montemurro F, Vozzi G (2017) A new 3D concentration gradient maker and its application in building hydrogels with a 3D stiffness gradient. J Tissue Eng Regen Med 11:256–264

Lo C-M, Wang H-B, Dembo M, Wang Y-L (2000) Cell movement is guided by the rigidity of the substrate. Biophys J 79:144–152

Wang H-B, Dembo M, Hanks SK, Wang Y-I (2001) Focal adhesion kinase is involved in mechanosensing during fibroblast migration. Proc Natl Acad Sci U S A 98:11295–11300

Raab M, Swift J, Dingal PCDP, Shah P, Shin J-W, Discher DE (2012) Crawling from soft to stiff matrix polarizes the cytoskeleton and phosphoregulates myosin-II heavy chain. J Cell Biol 199:669–683

Nemir S, Hayenga HN, West JL (2010) PEGDA hydrogels with patterned elasticity: novel tools for the study of cell response to substrate rigidity. Biotechnol Bioeng 105:636–644

Diederich VEG, Studer P, Kern A, Lattuada M, Storti G, Sharma RI, Snedeker JG, Morbidelli M (2013) Bioactive polyacrylamide hydrogels with gradients in mechanical stiffness. Biotechnol Bioeng 110:1508–1519

Du Y, Hancock MJ, He J, Villa-Uribe JL, Wang B, Cropek DM, Khademhosseini A (2010) Convection-driven generation of long-range material gradients. Biomaterials 31:2686–2694

Wong JY, Velasco A, Rajagopalan P, Pham Q (2003) Directed movement of vascular smooth muscle cells on gradient-compliant hydrogels. Langmuir 19:1908–1913

Kidoaki S, Matsuda T (2008) Microelastic gradient gelatinous gels to induce cellular mechanotaxis. J Biotechnol 133:225–230

Tse JR, Engler AJ (2011) Stiffness gradients mimicking in vivo tissue variation regulate mesenchymal stem cell fate. PLoS One 6:e15978

Marklein RA, Burdick JA (2010) Spatially controlled hydrogel mechanics to modulate stem cell interactions. Soft Matt 6:136–143

Khetan S, Burdick JA (2010) Patterning network structure to spatially control cellular remodeling and stem cell fate within 3-dimensional hydrogels. Biomaterials 31:8228–8234

Stowers RS, Allen SC, Suggs LJ (2015) Dynamic phototuing of 3D hydrogel stiffness. Proc Natl Acad Sci U S A 112:1953–1958

Kloxin AM, Benton JA, Anseth KS (2010) In situ elasticity modulation with dynamic substrates to direct cell phenotype. Biomaterials 31:1–8

Johnson PM, Reynolds TB, Stansbury JW, Bowman CN (2005) High throughput kinetic analysis of photopolymer conversion using composition and exposure time gradients. Polymer 46:3300–3306

Sunyer R, Jin AJ, Nossal R, Sackett DL (2012) Fabrication of hydrogels with steep stiffness gradients for studying cell mechanical response. PLoS One 7:e46107

García S, Sunyer R, Olivares A, Noailly J, Atencia J, Trepat X (2015) Generation of stable orthogonal graidents of chemical concentration and substrate stiffness in a microfluidic device. Lab Chip 15:2606–2614

Kloxin AM, Tibbitt MW, Kasko AM, Fairbairn JA, Anseth KS (2010) Tunable hydrogels for external manipulation of cellular microenvironments through controlled photodegradation. Adv Mater 22:61–66

Tong X, Jiang J, Zhu D, Yang F (2016) Hydrogels with dual gradients of mechanical and biochemical cues for deciphering cell-niche interactions. ACS Biomater Sci Eng 2:845–852

Yanagawa F, Mizutani T, Sugiura S, Takagi T, Sumaru K, Kanamori T (2015) Partially photodegradable hybrid hydrogels with elasticity tunable by light irradiation. Colloid Surf B 126:575–579

Kawano T, Kidoaki S (2011) Elasticity boundary conditions required for cell mechanotaxis on microelastically-patterned gels. Biomaterials 32:2725–2733

Mosiewicz KA, Kolb L, van der Vlies AJ, Lutolf MP (2014) Microscale patterning of hydrogel stiffness through light-triggered uncaging of thiols. Biomater Sci 2:1640–1651

Frey MT, Wang Y-L (2009) A photo-modulatable material for probing cellular responses to substrate rigidity. Soft Matt 5:1918–1924

Wang P-Y, Tsai W-B, Voelcker NH (2012) Screening of rat mesenchymal stem cell behaviour on polydimethylsiloxane stiffness gradients. Acta Biomater 8:519–530

Gray DS, Tien J, Chen CS (2003) Repositioning of cells by mechanotaxis on surfaces with micropatterned Young's modulus. J Biomed Mater Res A 66:605–614

Choi YS, Vincent LG, Lee AR, Kretchmer KC, Chirasatitsin S, Dobke MK, Engler AJ (2012) The alignment and fusion assembly of adipose-derived stem cells on mechanically patterned matrices. Biomaterials 33:6943–6951

Cheung YK, Azeloglu EU, Shiovitz DA, Costa KD, Seliktar D, Sia SK (2009) Microscale control of stiffness in a cell-adhesive substrate using microfluidics-based lithography. Angew Chem Int Ed 48:7188–7192

Shu Y, Chan HN, Guan D, Wu H, Ma L (2017) A simple fabricated thickness-based stiffness gradient for cell studies. Sci Bull 62:222–228

Kuo C-HR, Xian J, Brenton JD, Franze K, Sivaniah E (2012) Complex stiffness gradient substrates for studying mechanotatic cell migration. Adv Mater 24:6059–6064

Chao PG, Sheng S-C, Chang W-R (2014) Micro-composite substrates for the study of cell-matrix mechanical interactions. J Mech Behav Biomed Mater 38:232–241

Kim TH, An DB, Oh SH, Kang MK, Song HH, Lee JH (2015) Creating stiffness gradient polyvinyl alcohol hydrogel using a simple gradual freezing-thawing method to investigate stem cell differentiation behaviors. Biomaterials 40:51–60

Hopp I, Michelmore A, Smith LE, Robinson DE, Bachhuka A, Mierczynska A, Vasilev K (2013) The influence of substrate stiffness gradients on primary human dermal fibroblasts. Biomaterials 34:5070–5077

Tse JR, Engler AJ (2010) Preparation of hydrogel substrates with tunable mechanical properties. In: Current protocols in cell biology. John Wiley & Sons, Inc: 1–16

Lakins JN, Chin AR, Weaver VM (2012) Exploring the link between human embryonic stem cell organization and fate using tension-calibrated extracellular matrix functionalized polyacrylamide gels. In: Mace KA, Braun KM (eds) Progenitor cells, vol 916. Methods in molecular biology. Humana Press, Totawa, pp 317–350

Lee D, Rahman MM, Zhou Y, Ryu S (2015) Three-dimensional confocal microscopy indentation method for hydrogel elasticity measurement. Langmuir 31:9684–9693

Lee D, Ryu S (2017) A validation study of the repeatability and accuracy of atomic force microscopy indentation using polyacrylamide gels and colloidal probes. J Biomech Eng 139:044502

Graham PJ, Farhangi MM, Dolatabadi A (2012) Dynamics of droplet coalescence in response to increasing hydrophobicity. Phys Fluids 24:112105

Hancock MJ, Yanagawa F, Jang Y-H, He J, Kachouie NN, Kaji H, Khademhosseini A (2012) Designer hydrophilic regions regulate droplet shape for controlled surface patterning and 3D microgel synthesis. Small 8:393–403

Hermanowicz P, Sarna M, Burda K, Gabryś H (2014) AtomicJ: an open source software for analysis of force curves. Rev Sci Instrum 85:063703

Crank J (1975) The mathematics of diffusion. 2nd edn. Oxford University Press, Oxford, UK

Carey AE, Wheatcraft SW, Glass RJ, O'Rourke JP (1995) Non-Fickian ionic diffusion across high-concentration gradient. Water Resour Res 31:2213–2218

Küntz M, Lavallée P (2004) Anomalous diffusion is the rule in concentration-dependent diffusion processes. J Phys D Appl Phys 37:L5–L8

Wu Z, Nguyen N-T, Huang X (2004) Nonlinear diffusive mixing in microchannels: theory and experiments. J Micromech Microeng 14:604–611

Chen J, Kim HD, Kim KC (2013) Measurement of dissolved oxygen diffusion coefficient in a microchannel using UV-LED induced fluorescent method. Microfluid Nanofluid 14:541–550

Jimenez M, Dietrich N, Cockx A, Hébrard G (2013) Experimental study of O2 diffusion coefficient measurement at a planar gas-liquid interface by planar laser-induced fluorescence with inhibition. AICHE J 59:325–333

Jimenez M, Dietrich N, Grace JR, Hébrard G (2014) Oxgen mass transfer and hydrodynamic behaviour in wastewater: determination of local impact of surfactants by visualization techniques. Water Res 58:111–121

Roht YL, Auradou H, Hulin J-P, Salin D, Chertcoff R, Ippolito I (2015) Time dependence and local structure of tracer dispersion in oscillating liquid hele-Shaw flows. Phys Fluids 27:103602

Xu F, Jimenez M, Dietrich N, Hébrard G (2017) Fast determination of gas-liquid diffusion coefficient by an innovative double approach. Chem Eng Sci 170:68–76

Long R, Hall MS, Wu M, Hui C-Y (2011) Effects of gel thickness on microscopic indentation measurements of gel modulus. Biophys J 101:643–650

Calvet D, Wong JY, Giasson S (2004) Rheological monitoring of polyacrylamide gelation: importance of cross-link density and temperature. Macromolecules 37:7762–7771

Buxboim A, Rajagopalan K, Brown AEX, Discher DE (2010) How deeply cells feel: methods for thin gels. J Phys Condens Matter 22:194116

Markert CD, Guo X, Skardal A, Wang Z, haradwaj S, Zhang Y, Bonin K, Guthold M (2013) Characterizaing the micro-scale elastic modulus of hydrogels for use in regenerative medicine. J Mech Behav Biomed Mater 27:115–127

Abidine Y, Laurent VM, Michel R, Duperray A, Palade LI, Verdier C (2015) Physical properties of polyacrylamide gels probed by AFM and rheology. Eur Phys Lett 109:38003

Boudou T, Ohayon J, Picart C, Tracqui P (2006) An extended relationship for the characterization of Young's modulus and Poisson's ratio of tunable polyacrylamide gels. Biorheology 43:721–728

Damljanovic V, Lagerholm BC, Jacobson K (2005) Bulk and micropatterned conjugation of extracellular matrix proteins to characterized polyacrylamide substrates for cell mechanotransduction assays. Biotechniques 39:847–851

Takigawa T, Morino Y, Urayama K, Masuda T (1996) Poisson's ratio of polyacrylamide (PAAm) gels. Polym Gel Netw 4:1–5

Geissler E, Hecht AM (1980) The Poisson ratio in polymer gels. Macromolecules 13:1276–1280

Kalcioglu ZI, Mahmoodian R, Hu Y, Suo Z, Van Vliet KJ (2012) From macro- to microscale poroelastic characterization of polymeric hydrogels via indentation. Soft Matt 8:3393–3398

Geissler E, Hecht AM (1981) The Poisson ratio in polymer gels. 2. Macromolecules 14:185–188

Acknowledgements

This study was supported by Bioengineering for Human Health grant from the University of Nebraska-Lincoln (UNL) and the University of Nebraska Medical Centre (UNMC). KG appreciates UNL Undergraduate Creative Activities and Research Experiences (UCARE) program, and AM and BG appreciate UNL Summer Research Program and NSF Research Experiences for Undergraduates (REU) grant. AFM measurements were performed at the NanoEngineering Research Core Facility of UNL (part of the Nebraska Nanoscale Facility), which is partially funded from Nebraska Research Initiative Funds.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, D., Golden, K., Rahman, M.M. et al. Fabrication of Hydrogels with a Stiffness Gradient Using Limited Mixing in the Hele-Shaw Geometry. Exp Mech 59, 1249–1259 (2019). https://doi.org/10.1007/s11340-018-0416-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-018-0416-1