Abstract

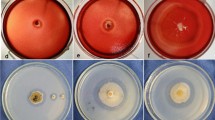

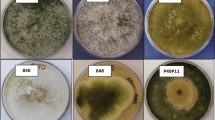

We investigated the enzymatic complex produced by selected fungi strains isolated from the environment using the agro-industrial residues rice husk, soybean hull, and spent malt as substrates. Microbial growth was carried out in solid-state cultivation (SSC) and in submerged cultivations (SC) and the enzymatic activities of xylanase, cellulase, β-xylosidase, and β-glucosidase were determined. All substrates were effective in inducing enzymatic activities, with one strain of Aspergillus brasiliensis BLf1 showing maximum activities for all enzymes, except for cellulases. Using this fungus, the enzymatic activities of xylanase, cellulase, and β-glucosidase were generally higher in SSC compared to SC, producing maxima activities of 120.5, 25.3 and 47.4 U g−1 of dry substrate, respectively. β-xylosidase activity of 28.1 U g−1 of dry substrate was highest in SC. Experimental design was carried out to optimize xylanase activity by A. brasiliensis BLf1 in SSC using rice husk as substrate, producing maximum xylanase activity 183.5 U g−1 dry substrate, and xylooligosaccharides were produced and characterized. These results suggest A. brasiliensis BLf1 can be used to produce important lytic enzymes to be applied in the preparation of xylooligosaccharides.

Similar content being viewed by others

References

Aachary AA and Prapulla SG (2011) Xylooligosaccharides (XOS) as emerging prebiotic: microbial synthesis, utilization, structural characterization, bioactive properties, and applications. Food Sci Food Safety 10: 2–16. doi:10.1111/j.1541-4337.2010.00135.x

Alves-Prado AF, Pavezzi FC, Leite RSR, Oliveira VM, Sette LD, Silva R (2010) Screening and production study os microbial xylanase producers from Brazilian Cerrado. Appl Biochem Biotechnol 161:333–346. doi:10.1007/s12010-009-8823-5

Anthony T, Chandra RK, Rajendran A, Gunasekaran P (2003) High molecular weight cellulase-free xylanase from alkali-tolerant Aspergillus fumigatus AR1. Enzyme Microb Technol 32: 647–654. doi:10.1016/S0141-0229(03)00050-4

AOAC. 2000. Association of official analytical chemists. Official methods of analysis (16th ed). Washington: Association of Official Analytical Chemists

Bajaj BK, Sharma M, Sharma S (2011) Alkalistable endo-β-1,4-xylanase production from a newly isolated alkali tolerant Penicillium sp. SS1 using agro-residues. Biotechnology 1: 83–90. doi:10.1007/s13205-011-0009-5

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energ Convers Manage 52:858–875. doi:10.1016/j.enconman.2010.08.013

Bansal N, Tewari R, Soni R, Sono SK (2012) Production of cellulases from Aspergillus niger NS-2 in solid-state fermentation on agricultural and kitchen waste residues. Waste Manage 32:1341–1346. doi:10.1016/j.wasman.2012.03.006

Belfaquih N, Jaspers C, Kurzatkowski W, Penninckx MJ (2002) Properties of Streptomyces sp. Endo-β-xylanases in relation to their applicability in kraft pulp bleaching. World J Microbiol Biotechnol 18:699–705. doi:10.1023/A:1016810018859

Brienzo M, Carvalho W, Milagres AMF (2010) Xylo-oligosaccharides production from alkali-pretreated sugarcane bagasse using xylanases from Thermoascus aurantiacus. Appl Biochem Biotechnol 162:1195–1205. doi:10.1007/s12010-009-8892-5

Cardona C, Quintero J, Paz I (2010) Production of bioethanol from sugarcane bagasse: status and perspectives. Bioresour Technol 101:4754–4766. doi:10.1016/j.biortech.2009.10.097

Delabona PS, Pirota RDPB, Codima CA, Tremacoldi CR, Rodrigues A, Farinas CS (2012) Using Amazon forest fungi and agricultural waste as a strategy to produce cellulolytic enzymes. Biomass Bioenergy 37:243–250. doi:10.1016/j.biombioe.2011.12.006

Delabona PS, Pirota RDPB, Codima CA, Tremacoldi CR, Rodrigues A, Farinas CS (2013) Effect of initial moisture content on two Amazon rainforest Aspergillus strains cultivated on agro-industrial residues: Biomass-degrading enzymes production and characterization. Ind Crops Prod 42:236–242. doi:10.1016/j.indcrop.2012.05.035

Dunning JW, Dallas DE (1949) Analytical procedures for control of sacharification operations. Anal Chem 21:727–729. doi:10.1021/ac60030a025

Farias D, Margarites AN, Reinehr CO, Colla LM, Costa JAV, Bertolin TE (2009) Amylolytic potential of maize malt in the process of sacarification of the same cereal. Ciênc Agrotec 33: 855–862. doi:10.1590/S1413-70542009000300027

Garcia NFL, Santos FRS, Gonçalves FA, Paz MF, Fonseca GG, Leite RSR (2015) Production of β-glucosidase on solid-state fermentation by Lichtheimia ramosa in agroindustrial residues: characterization and catalytic properties of the enzymatic extract. Electronic J Biotechnol 18:314–319. doi:10.1016/j.ejbt.2015.05.007

Gottschalk LMF, Paredes RS, Teixeira RSS, Silva AS, Bon EPS (2013) Efficient production of lignocellulolytic enzymes xylanase, β-xylosidase, ferulic acid esterase and β-glucosidase by the mutant strain Aspergillus awamori 2B.361 U2/1. Braz J Microbiol 44:569–576. doi:10.1590/S1517-83822013000200037

Gullón P, González-Muñoz MJ, Parajó JC (2011) Manufacture and prebiotic potential of oligosaccharides derived from industrial solid wastes. Bioresour Technol 102:6112–6119. doi:10.1016/j.biortech.2011.02.059

Hickert LR, Cunha-Pereira F, Souza-Cruz PB, Rosa CA, Ayub MAZ (2013) Ethanogenic cultivation of co-cultures of Candida shehatae HM 52.2 and Saccharomyces cerevisiae ICV D254 in synthetic medium and rice hull hydrolysate. Bioresour Technol 131:508–514. doi:10.1016/j.biortech.2012.12.135

Jayapal N, Samanta AK, Kolte AP, Senani S, Sridhar M, Suresh KP, Sampath KY (2013) Value addition to sugarcane bagasse: xylan extraction and its process optimization for xylooligosaccharides production. Ind Crops Prod 42:14–24. doi:10.1016/j.indcrop.2012.05.019

Kaushik P, Mishra A, Malik A (2014) Dual application of agricultural residues for xylanase production and dye removal through solid-state cultivation. Int Biodeter Biodegr 96: 1–8. doi:10.1016/j.ibiod.2014.08.006

Khurana S, Kapoor M, Gupta S, Kuhad RC (2007) Statistical optimization of alkaline xylanase production from Streptomyces violaceoruber under submerged cultivation using response surface methodology. Indian J Microbiol 47:144–152. doi:10.1007/s12088-007-0028-4

Kiran EU, Akpinar O, Bakir U (2013) Improvement of enzymatic xylooligosaccharides production by the co utilization of xylans from different origins. Food Bioprod Process 91, 565–574. doi:10.1016/j.fbp.2012.12.002

Kocabas DS, Ozben N (2014) Co-production of xylanase and xylooligosaccharides from lignocellulosic agricultural wastes. RSC Adv 4:26129–26139. doi:10.1039/C4RA02508C

Kumar R, Singh S, Singh O (2008) Bioconversion of lignocellulosic biomass: biochemical and molecular perspectives. J Ind Microbiol Biotechnol 35:377–391. doi:10.1007/s10295-008-0327-8

Miller GL (1959) Use of the dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. doi:10.1021/ac60147a030

Mussato SI, Dragone G, Roberto IC (2006) Brewers spent grain: generation, characteristics and potential applications. J Cereal Sci 43:1–14. doi:10.1016/j.jcs.2005.06.001

Nabarlatz D, Ebringerová A, Montané D (2007) Autohydrolysis of agricultural by-products for the production of xylooligosaccharides. Carbohydr Polym 69:20–28. doi:10.1016/j.carbpol.2006.08.020

Pandey P, Pandey A (2002) Production of cellulase-free thermostable xylanases by an isolated strain os Aspergillus niger PPI, utilizing various lignocellulosic wastes. World J Microbiol Biotechnol 18:281–283. doi:10.1023/A:1014999728406

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agroindustrial residues. I: sugarcane bagasse. Bioresour Technol 74:69–80. doi:10.1016/S0960-8524(99)00142-X

Park Y, Kang S, Lee J, Hong S, Kim S (2002) Xylanase production in solid state cultivation by Aspergillus niger mutant using statistical experimental designs. Appl Microbiol Biotechnol 58:761–766. doi:10.1007/s00253-002-0965-0

Qinnghe C, Xiaoyu Y, Tiangui N, Cheng J, Qiugang M (2004) The screening of culture condition and properties of xylanase by white-rot fungus. Pleurotus ostreatus. Process Biochem 39:1561–1566. doi:10.1016/S0032-9592(03)00290-5

Rabelo S, Maciel R, Costa A (2009) Lime pretreatment of sugarcane bagasse for bioethanol production. Appl Biochem Biotechnol 153:139–150. doi:10.1007/s12010-008-8433-7

Reading NS, Welch KD, Aust SD (2003) Free radical reactions of wood-degrading fungi. In: wood deterioration and preservation: advances in our changing world, Washington. ACS Symp Ser 845:16–31. doi:10.1021/bk-2003-0845

Saha B, Iten L, Cotta M, Wu V (2005) Dilute acid pretreatment, enzymatic saccharification, and cultivation of rice hulls to ethanol. Biotechnol Progress 21: 816–822. doi:10.1021/bp049564n

Schirmer-Michel AC, Flores SH, Hertz PF, Matos GS, Ayub MAZ (2008) Production of ethanol from soybean hull hydrolysate by osmotorelant Candida guilliermondii NRRL Y-2075. Bioresour Technol 99:2898–2904. doi:10.1016/j.biortech.2007.06.042

Silva R, Lago ES, Merheb CW, Macchione MM, Park YK, Gomes E (2005) Production of xylanaseand CMCase on solid-state fermentation in different residues by Thermoascus aurantiacus Miehe. Braz J Microbiol 36:235–241. doi:10.1590/S1517-83822005000300006

Souza RLA, Oliveira LSC, Silva FLH, Amorim BC (2010) Characterization of polygalacturonase produced by sild-state fermentation using the residue of passion fruit as substrate. Rev Bras Eng Agric Ambient 14: 987–992. doi:10.1590/S1415-43662010000900011

Sridevi B, Charya MAS (2011) Isolation, identification and screening of potential cellulase-free xylanase producing fungi. African. J Biotechnol 10:4624–4630. doi:10.5897/AJB10.2108

Sukumaran RK, Singhania RR, Mathew GM, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energy 34:421–424. doi:10.1016/j.renene.2008.05.008

Wang SH, Cabral LC, Fernandes SM (1997) Beverage based on rice and soybean hydrossoluble extract. Food Sci Technol 17: 73–77. doi:10.1590/S0101-20611997000200001

Zheng Z, Shetty K (2000) Solid state bioconversion of phenolics from Cranberry Pomace and role of Lentinus edodes β-glucosidases. J Agric Food Chem 48:895–900. doi:10.1021/jf990972u

Zimbardi ALRL, Sehn C, Meleiro LP, Souza FHM, Masui DC, Nozawa MSF, Guimarães LHS, Jorge JA, Furriel RPM (2013) Optimization of β-Glucosidase, β-Xylosidase and Xylanase Production by Colletotrichum graminicola under Solid-State Fermentation and Application in Raw Sugarcane Trash Saccharification. Int J Mol Sci 14:2875–2902. doi:10.3390/ijms14022875

Acknowledgements

The authors wish to thank the financial support of CNPq (Brazil) and scholarships for the first author from CAPES (Brazil).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Silva Menezes, B., Rossi, D.M. & Ayub, M.A.Z. Screening of filamentous fungi to produce xylanase and xylooligosaccharides in submerged and solid-state cultivations on rice husk, soybean hull, and spent malt as substrates. World J Microbiol Biotechnol 33, 58 (2017). https://doi.org/10.1007/s11274-017-2226-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-017-2226-5