Abstract

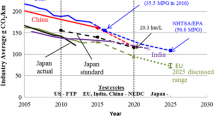

The demand for increased energy efficiency continuously drives the development of new lubricants. Here we report the design and synthesis of hexahydrotriazine, triazine, and cyclen derivatives as friction modifiers (FMs) for enhanced fuel economy. This series of sulfur- and phosphorus-free oil-soluble heterocyclic ring-based molecules exhibits differing thermal and chemical stability depending on the degree of aromatization and number of linking spacers within the central heterocyclic ring. Thermally stable triazine and cyclen FMs significantly increase friction performance in the boundary lubrication regime. Cyclens in particular reduce friction by up to 70% over a wide temperature range. Detailed experimental investigations of the newly synthesized FMs at elevated temperatures demonstrate their favorable tribological performance under four operating conditions: variable-temperature sliding, linear speed ramping, reciprocating sliding, and rolling–sliding contact. These latest experimental findings suggest the potential of the application of “designer” heterocyclic FMs for reducing frictional loss in motor vehicles.

Similar content being viewed by others

References

Chu, S., Majumdar, A.: Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012)

Schäfer, A., Heywood, J.B., Weiss, M.A.: Future fuel cell and internal combustion engine automobile technologies: a 25-year life cycle and fleet impact assessment. Energy 31, 2064–2087 (2006)

Greene, D.L., DeCicco, J.: Engineering-economic analyses of automotive fuel economy potential in the United States. Annu. Rev. Energy Environ. 25, 477–536 (2000)

Holmberg, K., Andersson, P., Erdemir, A.: Global energy consumption due to friction in passenger cars. Tribol. Int. 47, 221–234 (2012)

Holmberg, K., Andersson, P., Nylund, N.-O., Mäkelä, K., Erdemir, A.: Global energy consumption due to friction in trucks and buses. Tribol. Int. 78, 94–114 (2014)

Tung, S.C., McMillan, M.L.: Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 37, 517–536 (2004)

Wong, V.W., Tung, S.C.: Overview of automotive engine friction and reduction trends–effects of surface, material, and lubricant-additive technologies. Friction 4, 1–28 (2016)

Priest, M., Taylor, C.M.: Automobile engine tribology—approaching the surface. Wear 241, 193–203 (2000)

Zhu, D.: Mixed EHL. In: Wang, Q.J., Chung, Y.-W. (eds.) Encyclopedia of Tribology, pp. 2266–2276. Springer, Berlin (2013)

Bhushan, B.: Principles and Applications of Tribology. Wiley, New York (2013)

Hsu, S.M., Gates, R.S.: Boundary lubricating films: formation and lubrication mechanism. Tribol. Int. 38, 305–312 (2005)

Zhang, J., Meng, Y.: Boundary lubrication by adsorption film. Friction 3, 115–147 (2015)

Srivastava, S.P.: Advances in Lubricant Additives and Tribology. CRC Press, Boca Raton (2009)

Rudnick, L.R.: Lubricant Additives: Chemistry and Applications. CRC Press, Boca Raton (2009)

Spikes, H.: Friction modifier additives. Tribol. Lett. 60, 5 (2015)

Tang, Z., Li, S.: A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 18, 119–139 (2014)

Qu, J., Barnhill, W.C., Luo, H., Meyer, H.M., Leonard, D.N., Landauer, A.K., et al.: Synergistic effects between phosphonium-alkylphosphate ionic liquids and zinc dialkyldithiophosphate (ZDDP) as lubricant additives. Adv. Mater. 27, 4767–4774 (2015)

Palacio, M., Bhushan, B.: Ultrathin wear-resistant ionic liquid films for novel MEMS/NEMS applications. Adv. Mater. 20, 1194–1198 (2008)

Qu, J., Bansal, D.G., Yu, B., Howe, J.Y., Luo, H., Dai, S., et al.: Antiwear performance and mechanism of an oil-miscible ionic liquid as a lubricant additive. ACS Appl. Mater. Interfaces 4, 997–1002 (2012)

Gauvin, M., Zheng, H., Suen, B., Lee, J., Kang, H.J., Talke, F.E.: Enhanced photo-thermal stability of modified PFPE lubricants under laser beam exposure. IEEE Trans. Magn. 47, 1849–1854 (2011)

Kang, H.-J., Perettie, D.J., Talke, F.E.: A study of phase separation characteristics of perfluoropolyether/phosphazene (X-1P) lubricant mixtures on hard disk surfaces. Tribol. Lett. 35, 2385–2387 (1999)

Miller, B.P., Theodore, N.D., Brukman, M.J., Wahl, K.J., Krim, J.: A nano-to macroscale tribological study of PFTS and TCP lubricants for Si MEMS applications. Tribol. Lett. 38, 69–78 (2010)

Desanker, M., Johnson, B., Seyam, A.M., Chung, Y.-W., Bazzi, H.S., Delferro, M., et al.: Oil-soluble silver-organic molecule for in situ deposition of lubricious metallic silver at high temperatures. ACS Appl. Mater. Interfaces 8, 13637–13645 (2016)

Desanker, M., He, X., Lu, J., Liu, P., Pickens, D.B., Delferro, M., et al.: Alkyl-cyclens as effective sulfur- and phosphorus-free friction modifiers for boundary lubrication. ACS Appl. Mater. Interfaces 9, 9118–9125 (2017)

Muraki, M., Yanagi, Y., Sakaguchi, K.: Synergistic effect on frictional characteristics under rolling–sliding conditions due to a combination of molybdenum dialkyldithiocarbamate and zinc dialkyldithiophosphate. Tribol. Int. 30, 69–75 (1997)

Miklozic, K.T., Graham, J., Spikes, H.: Chemical and physical analysis of reaction films formed by molybdenum dialkyl-dithiocarbamate friction modifier additive using Raman and atomic force microscopy. Tribol. Lett. 11, 71–81 (2001)

Morina, A., Neville, A., Priest, M., Green, J.H.: ZDDP and MoDTC interactions and their effect on tribological performance—tribofilm characteristics and its evolution. Tribol. Lett. 24, 243–256 (2006)

Morina, A., Neville, A., Priest, M., Green, J.H.: ZDDP and MoDTC interactions in boundary lubrication—the effect of temperature and ZDDP/MoDTC ratio. Tribol. Int. 39, 1545–1557 (2006)

Georges, E., Georges, J.-M., Diraison, C.: Rheology of olefinic copolymer layers adsorbed on solid surfaces. Tribol. Trans. 39, 563–570 (1996)

Cann, P.M., Spikes, H.A.: The behavior of polymer solutions in concentrated contacts: immobile surface layer formation. Tribol. Trans. 37, 580–586 (1994)

Liu, L., Sun, C., Li, Z., Chen, Y., Qian, X., Wen, S., et al.: In-chain functionalized polymer induced assembly of nanoparticles: toward materials with tailored properties. Soft Matter 12, 1964–1968 (2016)

Aoki, S., Yamada, Y., Fukada, D., Suzuki, A., Masuko, M.: Verification of the advantages in friction-reducing performance of organic polymers having multiple adsorption sites. Tribol. Int. 59, 57–66 (2013)

Guangteng, G., Smeeth, M., Cann, P.M., Spikes, H.A.: Measurement and modelling of boundary film properties of polymeric lubricant additives. Proc. Inst. Mech. Eng. J J. Eng. 210, 1–15 (1996)

Spear, J.C., Ewers, B.W., Batteas, J.D.: 2D-nanomaterials for controlling friction and wear at interfaces. Nano Today 10, 301–314 (2015)

Scharf, T.W., Prasad, S.V.: Solid lubricants: a review. J. Mater. Sci. 48, 511–531 (2013)

He, X., Xiao, H., Kyle, J.P., Terrell, E.J., Liang, H.: Two-dimensional nanostructured Y2O3 particles for viscosity modification. Appl. Phys. Lett. 104, 163107 (2014)

He, X., Xiao, H., Choi, H., Díaz, A., Mosby, B., Clearfield, A., et al.: α-Zirconium phosphate nanoplatelets as lubricant additives. Colloids Surf. A 452, 32–38 (2014)

Dou, X., Koltonow, A.R., He, X., Jang, H.D., Wang, Q., Chung, Y.-W., et al.: Self-dispersed crumpled graphene balls in oil for friction and wear reduction. Proc. Natl. Acad. Sci. USA 113, 1528–1533 (2016)

Dai, W., Kheireddin, B., Gao, H., Liang, H.: Roles of nanoparticles in oil lubrication. Tribol. Int. 102, 88–98 (2016)

Lee, K., Hwang, Y., Cheong, S., Choi, Y., Kwon, L., Lee, J., et al.: Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 35, 127–131 (2009)

Berman, D., Erdemir, A., Sumant, A.V.: Graphene: a new emerging lubricant. Mater. Today 17, 31–42 (2014)

Liu, W., Ye, C., Zhang, Z., Yu, L.: Relationship between molecular structures and tribological properties of phosphazene lubricants. Wear 252, 394–400 (2002)

Waltman, R.J., Kobayashi, N., Shirai, K., Khurshudov, A., Deng, H.: The tribological properties of a new cyclotriphosphazene-terminated perfluoropolyether lubricant. Tribol. Lett. 16, 151–162 (2004)

Liu, W., Zhu, J., Liang, Y.: Effect of bridged cyclotriphosphazenes as lubricants on the tribological properties of a steel-on-steel system. Wear 258, 725–729 (2005)

Nader, B.S., Kar, K.K., Morgan, T.A., Pawloski, C.E., Dilling, W.L.: Development and tribological properties of new cyclotriphosphazene high temperature lubricants for aircraft gas turbine engines. Tribol. Trans. 35, 37–44 (1992)

Kasai, P.H., Wakabayashi, A.: Disk lubricant additives, A20H and C2: characteristics and chemistry in the disk environment. Tribol. Lett. 31, 25–35 (2008)

Graymore, J.: 175. The reduction products of certain cyclic methyleneamines: Part II. J. Chem. Soc. https://doi.org/10.1039/JR9320001353 (1932)

Jones, G.O., García, J.M., Horn, H.W., Hedrick, J.L.: Computational and experimental studies on the mechanism of formation of poly(hexahydrotriazine)s and poly(hemiaminal)s from the reactions of amines with formaldehyde. Org. Lett. 16, 5502–5505 (2014)

Xiangqiong, Z., Heyang, S., Wenqi, R., Zhongyi, H., Tianhui, R.: Tribological study of trioctylthiotriazine derivative as lubricating oil additive. Wear 258, 800–805 (2005)

Xiong, X.-Q., Liang, F., Yang, L., Wang, X.-L., Zhou, X., Zheng, C.-Y., et al.: Transcription-Inhibition and antitumor activities of N-alkylated tetraazacyclododecanes. Chem. Biodivers. 4, 2191–2797 (2007)

Wuest, J.D., Rochefort, A.: Strong adsorption of aminotriazines on graphene. Chem. Commun. 46, 2923–2925 (2010)

Zhu, D., Wang, Q.J.: Elastohydrodynamic lubrication: a gateway to interfacial mechanics—review and prospect. J. Tribol. 133, 041001 (2011)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts: part 1—theoretical formulation. J. Lubr. Technol. 98, 223–228 (1976)

Chapkov, A.D., Bair, S., Cann, P., Lubrecht, A.A.: Film thickness in point contacts under generalized Newtonian EHL conditions: numerical and experimental analysis. Tribol. Int. 40, 1474–1478 (2007)

Krupka, I., Bair, S., Kumar, P., Khonsari, M.M., Hartl, M.: An experimental validation of the recently discovered scale effect in generalized Newtonian EHL. Tribol. Lett. 33, 127–135 (2009)

Campen, S., Green, J.H., Lamb, G.D., Spikes, H.A.: In situ study of model organic friction modifiers using liquid cell AFM: self-assembly of octadecylamine. Tribol. Lett. 58, 39 (2015)

He, X., Lu, J., Desanker, M., Invergo, A.M., Lohr, T.L., Ren, N., et al.: Boundary lubrication mechanisms for high-performance friction modifiers. Submitted (2018)

Acknowledgements

The authors gratefully acknowledge financial support from the US Department of Energy under contract DE-EE0006449. Argonne National Laboratory was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract DE-AC02-06CH11357. The NMR instrumentation at IMSERC was supported by the National Science Foundation under CHE-9871268, and GC–MS instrumentation was supported by a donation from Pfizer. M. Desanker was supported by the Department of Defense (DoD) through the National Defense Science and Engineering Graduate Fellowship (NDSEG) Program. We thank AkzoNobel for generously providing Armeen T® to us. We would also like to thank Mr. L. Kangmeng and R. Xu for helping in disk preparation, and Ms. X. Cheng for the assistance with rolling–sliding friction data collection.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare the following competing financial interest(s): A patent application related to this work has been filed (US Patent Application PCT/US2016/031868).

Rights and permissions

About this article

Cite this article

Desanker, M., He, X., Lu, J. et al. High-Performance Heterocyclic Friction Modifiers for Boundary Lubrication. Tribol Lett 66, 50 (2018). https://doi.org/10.1007/s11249-018-0996-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-0996-z