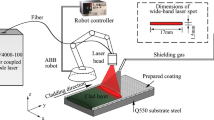

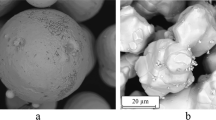

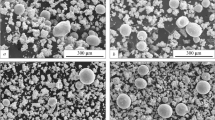

A ternary mixture of tungsten carbide (WC), cobalt (Co), and nickel (Ni) powders is prepared to form ceramic-metal composite coatings employed for laser cladding of 40Cr steel. This coating is investigated using the mixture design to evaluate the influence of its ratios on the residual stresses in the clads. The WC/Co/Ni ternary mixture exhibits higher residual stresses than those of the Co/Ni or WC/Ni binary mixtures, except for the WC/Co one. Single WC, Co, or Ni designs illustrate a high sensitivity of residual stresses, cracks pass through the interior of WC particles rather than around them, and the cracks mostly propagate along the eutectic phases at 50%Co–50%WC. A reduced special quartic model in the mixture design exhibits excellent fit, predicted and experimental values of residual stresses for these laser clads are in good agreement.

Similar content being viewed by others

References

P. Wen, Z. Feng, and S. Zheng, “Formation quality optimization of laser hot wire cladding for repairing martensite precipitation hardening stainless steel,” Opt. Laser Technol., 65, 180–188 (2015).

D. Shu, Z. Li, C. Yao, et al., “In situ synthesised WC reinforced nickel coating by laser cladding,” Surf. Eng., 33, No. 4, 276–282 (2017).

B. M. Dhakar, D. K. Dwivedi, and S. P. Sharma, “Studies on remelting of tungsten carbide and rare earth modified nickel base alloy composite coating,” Surf. Eng., 28, No. 1, 73–80 (2012).

C. Wang, C. Jiang, and V. Ji, “Thermal stability of residual stresses and work hardening of shot peened tungsten cemented carbide,” J. Mater. Process. Tech., 240, 98–103 (2017).

D. Shu, Z. Li, K. Zhang, et al., “In situ synthesized high volume fraction WC reinforced Ni-based coating by laser cladding,” Mater. Lett., 195, 178–181 (2017).

Q. Luo and A. H. Jones, “High-precision determination of residual stress of polycrystalline coatings using optimised XRD-sin 2ψ technique,” Surf. Coat. Tech., 205, No. 5, 1403–1408 (2010).

T. Mukherjee, W. Zhang, and T. DebRoy, “An improved prediction of residual stresses and distortion in additive manufacturing,” Comp. Mater. Sci., 126, 360–372 (2017).

M. L. Zhong, W. J. Liu, K. F. Yao, et al., “Microstructural evolution in high power laser cladding of Stellite 6+WC layers,” Surf. Coat. Tech., 157, Nos. 2–3, 128–137 (2002).

K. Zhang, J. Deng, Y. Xing, et al., “Periodic nano-ripples structures fabricated on WC/Co based TiAlN coatings by femtosecond pulsed laser,” Surf. Eng., 31, No. 4, 271–281 (2015).

M. Afzal, A. N. Khan, T. B. Mahmud, et al., “Effect of laser melting on plasma sprayed WC-12 wt.%Co coatings,” Surf. Coat. Tech., 266, 22–30 (2015).

U. de Oliveira, V. Ocelik, and J. Th. M. De Hosson, “Residual stress analysis in Co-based laser clad layers by laboratory X-rays and synchrotron diffraction techniques,” Surf. Coat. Tech., 201, Nos. 3–4, 533–542 (2006).

R. H. Myers, D. C. Montgomery, and C. M. Anderson-Cook, Response Surface Methodology: Process and Product Optimization Using Designed Experiments, John Wiley & Sons, New York (2009).

B. T. Lin, M. D. Jean, and J. H. Chou, “Using response surface methodology for optimizing deposited partially stabilized zirconia in plasma spraying,” Appl. Surf. Sci., 253, No. 6, 3254–3262 (2007).

Y. Rostamiyan, A. Fereidoon, A. G. Ghalebahman, et al., “Experimental study and optimization of damping properties of epoxy-based nanocomposite: Effect of using nanosilica and high-impact polystyrene by mixture design approach,” Mater. Design, 65, 1236–1244 (2015).

N. S. Pillai, P. S. Kannan, S. C. Vettivel, and S. Suresh, “Optimization of transesterification of biodiesel using green catalyst derived from Albizia Lebbeck Pods by mixture design,” Renew. Energ., 104, 185–196 (2017).

S. F. Zhou, J. B. Lei, X. Q. Dai, et al., “A comparative study of the structure and wear resistance of NiCrBSi/50 wt.% WC composite coatings by laser cladding and laser induction hybrid cladding,” Int. J. Refract. Met. H., 60, 17–27 (2016).

Acknowledgments

This work was financially supported by the Foundation of Fujian Provincial Education Department China (Grant Nos. 2018J01628, JA14208 and JA14216).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 108 – 114, January – February, 2019.

Rights and permissions

About this article

Cite this article

Liu, C.W., Jean, M.D., Wang, Q.T. et al. Optimization of Residual Stresses in Laser-Mixed WC(Co, Ni) Coatings. Strength Mater 51, 95–101 (2019). https://doi.org/10.1007/s11223-019-00054-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00054-z