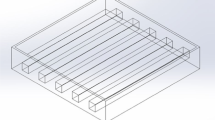

For studying the temperature field of hot stamping, the effect of the distance between cooling pipes, the distance between the cooling pipe and mold surface, and the water cooling pipe diameter were evaluated with ANSYS software. The results showed that the maximum temperature was about 50°C, and the maximum temperature difference of hot stamping was less than 35°C. The maximum temperature and the uniformity of stamping temperature can be improved by controlling the size and spacing of cooling pipes.

Similar content being viewed by others

References

Y. Kang, G. Chen, G. Zhu, and R. Song, “Forming technology and application of new generation advanced high strength steel for automobile,” Iron Steel, 45, No. 8, 1–6, 19 (2010).

L. Fan, “The fatigue analysis and structural optimization to advanced high-strength steel stamping die,” J. Hunan Univ. (2014).

T. T. Wu, “The forming process analysis and mold development to high-strength steel car cover,” J. Shandong Univ. (2015).

Z. Zhang, “The hot stamping technology and numerical simulation to high-strength steel plate,” Metal Cast. Forg. Technol., 19–23 (2010).

X. Wu, “The study on impact of die gap on thermoforming and its and optimization method,” J. Hunan Univ. (2015).

W. Bi, The Numerical simulation and Application of Hot Stamping Process for Automobile Axle Housing [in Chinese], Doctoral Thesis of Jilin University (2009).

R. Wu, “The fatigue life analysis and structural topology optimization to high-strength steel stamping die,” J. Hunan Univ. (2015).

B. Ding, “The study on fatigue life of ultra-high strength steel plate hot stamping die,” J. Chongqing Jiaotong Univ. (2015).

Acknowledgments

This study was performed within framework of two projects of Jilin Provincial Science and Technology Department, China, namely: “Study on Ultra-High Gradient Parts Preparation Process and Organizational Performance Based on Zoning Stamping” (No. 20150060) and “Research on 22MnB5 Ultra-High Strength Steel Hot Stamping Process” (No. 20140078).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 138 – 143, January – February, 2018.

Rights and permissions

About this article

Cite this article

Jiang, Q.Y., Zhao, H.Y. & Yang, H.F. Numerical Simulation of the Thermomechanical Behavior of a Hot Stamping Die. Strength Mater 50, 124–129 (2018). https://doi.org/10.1007/s11223-018-9950-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-018-9950-4