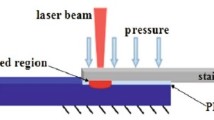

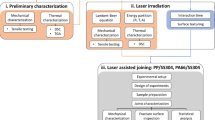

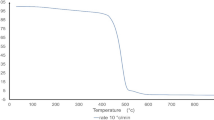

The thermosetting plastic and stainless steel were joined with a fiber laser. The influence of processing parameters on the joint was studied. The laser scanning on stainless steel is shown to result in the formation of the heat-affected and fusion zones. In the first zone, lathy ferrite precipitates along the boundary, which modifies austenite, while in the second zone, ferrite forms the skeleton structure and separates austenite into a small cellular structure. The laser joining improves the microstructure of both zones. With an increase in the laser scanning speed and power, the shear strength of the stainless steel/plastic joint first increases and then decreases. A low laser scanning speed or high laser power would overheat polyphenylene sulphide and lead to its decomposition. Those factors would also reduce heat transfer and lead to its insufficient melting. The stainless steel/plastic joint acquires a maximum shear strength at a laser scanning speed of 4–5 mm/s and laser power of 320-350 W.

Similar content being viewed by others

References

X. L. Zhao and L. Zhang, “State-of-the-art review on FRP strengthened steel structures,” Eng. Struct., 29, 1808–1823 (2007).

F. Lambiase, S. Genna, C. Leone, and A. Paoletti, “Laser-assisted direct-joining of carbon fibre reinforced plastic with thermosetting matrix to polycarbonate sheets,” Opt. Laser Technol., 94, 45–58 (2017).

G. Williams, R. Trask, and I. Bond, “A self-healing carbon fiber reinforced polymer for aerospace applications,” Compos. Part A-Appl. S., 38, No. 6, 1525–32 (2007).

A. Mayyas, A. Qattawi, M. Omar, and D. Shan, “Design for sustainability in automotive industry: a comprehensive review,” Renew. Sust. Energ. Rev., 16, No. 4, 1845–62 (2012).

Z. Zhang, J. Shan, X. Tan, and J. Zhang, “Improvement of the laser joining of CFRP and aluminum via laser pre-treatment,” Int. J. Adv. Manuf. Technol., 90, Nos. 9–12, 3465–3472 (2017).

G. Marannano and B. Zuccarello, “Numerical experimental analysis of hybrid double lap aluminum-CFRP Joints,” Compos. Part B-Eng., 71, 28–39 (2015).

J. Kweon, J. Jung, T. Kim, et al., “Failure of carbon composite-to-aluminum joints with combined mechanical fastening and adhesive bonding,” Compos. Struct., 75, 192–198 (2006).

P. P. Camanho, A. Fink, A. Obst, and S. Pimenta, “Hybrid titanium-CFRP laminates for high-performance bolted joints,” Compos. Part A-Appl. S., 40, No. 12, 1826–1837 (2009).

S. M. Goushegir, “Friction spot joining (FSPJ) of aluminum-CFRP hybrid structures,” Weld World, 60, No. 6, 1073–1093 (2016).

J. Min, Y. Li, J. Li, et al., “Friction stir blind riveting of carbon fiber-reinforced polymer composite and aluminum alloy sheets,” Int. J. Adv. Manuf. Technol., 76, No. 5, 1403–1410 (2015).

S. Katayama and Y. Kawahito, “Laser direct joining of metal and plastic,” Scripta Mater., 59, 1247–1250 (2008).

X. Tan, J. Shan, and J. Ren, “Effects of Cr plating layer on shear strength and interface bonding characteristics of mild steel/CFRP joint by laser heating,” Acta Metall. Sin., 49, 751–756 (2013).

X. H. Tan, J. Zhang, J. G. Shan, et al., “Characteristics and formation mechanism of porosities in CFRP during laser joining of CFRP and steel,” Compos. Part B-Eng., 70, 35–43 (2015).

L. Y. Sheng, F. Yang, T. F. Xi, et al., “Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling,” Compos. Part B-Eng., 42, No. 6, 1468–1473 (2011).

K. W. Jung, Y. Kawahito, and S. Katayama, “Laser direct joining of carbon fibre reinforced plastic to stainless steel,” Sci. Technol. Weld Joint, 16, No. 8, 676–80 (2011).

J. Jiao, Q. Wang, F. Wang, et al., “Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers,” J. Mater. Process. Tech., 240, 362–369 (2017).

J. Jiao, Z. Xu, Q. Wang, et al., “CFRTP and stainless steel laser joining: Thermal defects analysis and joining parameters optimization,” Opt. Laser Technol., 103, 170–176 (2018).

H. Di, Q. Sun, X. Wang, and J. Li, “Microstructure and properties in dissimilar/ similar weld joints between DP780 and DP980 steels processed by fiber laser welding,” J. Mater. Sci. Technol., 33, No. 12, 1561–1571 (2017).

L. J. Wang, L. Y. Sheng, and C. M. Hong, “Influence of grain boundary carbides on mechanical properties of high nitrogen austenitic stainless steel,” Mater. Design, 37, 349–355 (2012).

M. Alali, I. Todd, and B. P. Wynne, “Through-thickness microstructure and mechanical properties of electron beam welded 20 mm thick AISI 316L austenitic stainless steel,” Mater. Design, 130, 488–500 (2017).

L. Y. Sheng, F. Yang, T. F. Xi, et al., “Microstructure and elevated temperature tensile behaviour of directionally solidified nickel based superalloy,” Mater. Res. Innov., 17, No. S1, 101–106 (2013).

L. Y. Sheng, F. Yang, T. F. Xi, et al., “Microstructure evolution and mechanical properties of Ni3Al/Al2O3 composite during self-propagation high-temperature synthesis and hot extrusion,” Mater. Sci. Eng. A, 555, 131–138 (2012).

L. Y. Sheng, B. N. Du, B. J. Wang, et al., “Hot extrusion effect on the microstructure and mechanical properties of an Mg–Y–Nd–Zr alloy,” Strength Mater., 50, No. 1, 184–192 (2018).

L. Y. Sheng, W. Zhang, J. T. Guo, et al., “Microstructure and mechanical properties of Ni3Al fabricated by thermal explosion and hot extrusion,” Intermetallics, 17, No. 7, 572–577 (2009).

L. Sheng, F. Yang, T. Xi, et al., “Microstructure and room temperature mechanical properties of NiAl–Cr (Mo)–(Hf, Dy) hypoeutectic alloy prepared by injection casting,” Trans. Nonferrous Met. Soc. China, 23, No. 4, 983–990 (2013).

K. W. Jung, Y. Kawahito, and S. Katayama, “Laser direct joining of carbon fiber-reinforced plastic to stainless steel,” Sci. Technol. Weld Joint, 16, 676–680 (2011).

M. Wahba, Y. Kawahito, and S. Katayama, “Laser direct joining of AZ91D thixomolded Mg alloy and amorphous polyethylene terephthalate,” J. Mater. Process. Tech., 211, No. 6, 1166–1174 (2011).

Acknowledgments

The authors are grateful to the support of Shenzhen Basic Research Projects (JCYJ20150529162228734, JCYJ20160427170611414, and JCYJ20170306141506805).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 5, pp. 76 – 88, September – October, 2018.

Rights and permissions

About this article

Cite this article

Sheng, L.Y., Jiao, J.K. & Lai, C. Assessment of the Microstructure and Mechanical Properties of a Laser-Joined Carbon Fiber-Reinforced Thermosetting Plastic and Stainless Steel. Strength Mater 50, 752–763 (2018). https://doi.org/10.1007/s11223-018-0020-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-018-0020-8