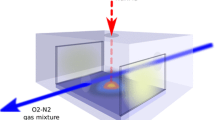

Ultrafine powders and colloid solutions of nanoparticles are fabricated by nanosecond pulsed laser ablation (a Nd:YAG laser, 1064 nm, 7 ns, 150 mJ, and 20 Hz) of metallic magnesium targets in water and organic solvents of different polarities (ethyl alcohol, ethyl acetate, and n-hexane). The morphology, dimensional characteristics, composition, and structure of the particles are studied by the methods of transmission electron microscopy, x-ray diffraction, and Fourier-transform infrared spectroscopy depending on the solvent used. For the first time it has been demonstrated that nanostructures of magnesium oxyhydroxide Mg5O(OH)8 are formed during the ablation in water. It is established that in organic solvents, formation of hexagonal and cubic magnesium oxides is possible. Nanoparticles fabricated by the ablation in less thermostable solvents – ethyl acetate and hexane – contain carbonates.

Similar content being viewed by others

Change history

08 November 2018

There was a misprint in the second author’s name. It should read D. A. Goncharova instead of D. A. Goncharov.

References

M. Sain, S. H. Park, F. Suhara, and S. Law, Polym. Degrad. Stab., 83, 363–367 (2004).

J. L. Booster, A. V. Sandwijk, and M. A. Reuter, Miner. Eng., 16, 273–281 (2003).

J. Kang and P. Schwendeman, Biomaterials, 23, 239–245 (2002).

C. Henrist, J. P. Mathieu, C. Vogels, et al., J. Cryst. Growth, 249, 321–330 (2003).

Y. D. Li, M. Sui, Y. Ding, et al., Adv. Mater., 12, 818–821 (2000).

H. Chen, C. Xu, Y. Liu, and G. Zhao, Electron. Mater. Lett., 8, 529–533 (2012).

W. L. Fan, S. X. Sun, L. P. You, et al., J. Mater. Chem., 13, 3062–3065 (2003).

B. Li, H. Cao, and G. Yin, J. Mater. Chem., 21, 13765–13768 (2011).

J. P. Lv, L. Z. Qiu, and B. J. Qu, J. Cryst. Growth, 267, 676–684 (2004).

C. Liang, T. Sasaki, Y. Shimizu, and N. Koshizaki, Chem. Phys. Lett., 389, 58–63 (2004).

T. X. Phuoc, B. H. Howard, D. V. Martello, et al., Opt. Laser. Eng., 46, 829–834 (2008).

F. Abrinaei, J. Opt. Soc. Am. B, 33, No. 5, 864–869 (2016).

K. J. Klabunde, J. V. Stark, O. Koper, et al., J. Phys. Chem., 100, No. 30, 12142–12153 (1996).

R. Richards, W. F. Li, S. Decker, et al., J. Am. Chem. Soc., 122, No. 20, 4921–4925 (2000).

K. Y. Niu, J. Yang, S. A. Kulinich, et al., J. Am. Chem. Soc., 132, No. 28, 9814–9819 (2010).

Z. Yan, R. Bao, C. M. Busta, and D. B. Chrisey, Nanotechnology, 22, Art. No. 265610, 1–8 (2011).

F. Abrinaei, M. J. Torkamany, M. R. Hantezadeh, and J. Sabbaghzadeh, Sci. Adv. Mater., 4, No. 3/4, 501–506 (2012).

A. Schwenke, P. Wagener, S. Nolte, and S. Barcikowski, Appl. Phys. A, 104, 77–82 (2011).

K. S. Khashan and F. Mahdi, Surf. Rev. Lett., 24, No. 7, Art. No. 1750101, 1–7 (2017).

F. Abrinaei, J. Eur. Opt. Soc.-Rapid Publ., 13, No. 15, 1–10 (2017).

V. A. Svetlichnyi and I. N. Lapin, Russ. Phys. J., 56, No. 5, 581–587 (2013).

V. A. Svetlichnyi and I. N. Lapin, Russ. Phys. J., 57, No. 12, 1789–1792 (2014).

M. J. McKelvy, R. Sharma, A. V. G. Chizgridya, and R. W. Carpenter, Chem. Mater., 13, No. 3, 921–926 (2001).

L.-X. Li, D. Xu, X.-Q. Li, et al., New J. Chem., 38, 5445–5452 (2014).

S. Xie, X. Han, Q. Kuang, et al., J. Mater. Chem., 21, 7263–7268 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 6, pp. 42–48, June, 2018.

Rights and permissions

About this article

Cite this article

Svetlichnyi, V.A., Goncharov, D.A., Lapin, I.N. et al. Influence of the Solvent on the Structure and Morphology of Nanoparticles Fabricated by Laser Ablation of Bulk Magnesium Targets. Russ Phys J 61, 1047–1053 (2018). https://doi.org/10.1007/s11182-018-1495-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-018-1495-2