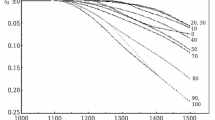

Using dilatometry, kinetic principles of sintering of composite ZrO2(Y)–Al2O3 ceramic material made from ultrafine powders synthesized at the Siberian Chemical Integrated Works are investigated. It is shown that under heating conditions, sintering of the composite ceramics under study occurs within a few stages that are closely related to the structural-phase transformations taking place in the composite powder mixture. At the firing temperatures Т > 1500 С and during long isothermal times, negative phenomena develop in the ceramic material, which give rise to its undesired dilatation and cracking in the course of cooling.

Similar content being viewed by others

References

V. Naglieri, P. Palmero, and L. Montanaro, J. Therm. Anal. Calorim., 97, 231–237 (2009).

R. H. J. Hannik, P. M. Kelly, and B. C. Muddle, J. Am. Ceram. Soc., 83(3), 461–487 (2000).

M. C. Moraes, C. N. Elias, J. D. Filho, and L. G. Oliviera, Mater Res., 7(4), 643–649 (2004).

C. Santos, L. H. P. Teixiera, J. K. M. F, Daguano, et al., Cerami. Int., 35, 709–718 (2009).

F. A.T. Guimares, K. L. Silva, V. Trombini, et al., Ceram. Int., 35, 741–745 (2009).

W. H. Tuan, R. Z. Chen, T. C. Wang, et al., J. Eur. Ceram. Soc., 22, 2827–2833 (2002).

V. K. Larin, V. M. Kondakov, E. N. Malyi, et al., Izvestiya VUZov.Chern. Metallurg., No. 5, 59–64 (2003).

A. I. Slosman, N. N. Aparov, L. S. Aparova, and S. V. Matrenin, Refr. Industr. Cer., No. 2, 4–7 (1994).

A. P. Surzhikov, T. S. Frangulyan, and S. A. Ghyngazov, Russ. Phys. J., 55, No. 4, xx – xx (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 3, pp. 116–120, March, 2014.

Rights and permissions

About this article

Cite this article

Surzhikov, A.P., Frangulyan, T.S., Ghyngazov, S.A. et al. A Dilatometric Study of Sintering of Composite Ceramics Manufactured from Ultrafine Zro2(Y)–Al2O3 Powders Under Different Thermal-Temporal Firing Conditions. Russ Phys J 57, 411–415 (2014). https://doi.org/10.1007/s11182-014-0254-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-014-0254-2