Abstract

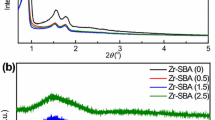

A novel and simple method to synthesize supported Ni2P/Na(x)-MCM-41 catalysts (where x is the mass fraction of Na-to-MCM-41 in terms of percentage) at a lower reduction temperature by incorporation of Na was described. The catalysts were characterized by H2 temperature-programmed reduction (H2-TPR), X-ray diffraction (XRD), N2 adsorption–desorption, CO uptake, X-ray photoelectron spectroscopy (XPS), and transmission electron microscopy (TEM). The effect of Na on the structure of catalysts and catalytic properties for the dibenzothiophene (DBT) hydrodesulfurization (HDS) was investigated, which confirmed that a suitable amount of Na can promote highly dispersed Ni2P particles. The Na preferentially interacts with phosphate to generate the sodium phosphate and therefore suppresses the formation of stronger P–O–P bonds, which enables the phosphide catalyst to be easily formed at a lower reduction temperature. Compared with conventional phosphate (973–1273 K), the reduction temperature of Ni2P/Na(x)-MCM-41 catalyst was relatively low (773 K). The Ni2P/Na(x)-MCM-41 catalyst with x = 1.0 showed the maximum DBT conversion of 91.6%, which is higher than that of Ni2P/M41 without Na (80.3%).

Similar content being viewed by others

References

M. Egorova, R. Prins, J. Catal. 255, 417 (2004)

Q.Y. Li, P.Y. Wu, L. Lan, H. Liu, S.F. Ji, Catal. Today 216, 38 (2013)

H.Y. Zhao, S.T. Oyama, H.J. Freund, R. Włodarczyk, M. Sierka, Appl. Catal. B 164, 204 (2015)

X. Li, Z.C. Sun, A.J. Wang, X.N. Yang, Y. Wang, Appl. Catal. A 417, 19 (2012)

S. Tian, X. Li, A. Wang, R. Prins et al., Angew. Chem. Int. Edit. 55, 4030 (2016)

C.P. Jiménez-Gómez, J.A. Cecilia, R. Moreno-Tost et al., ChemCatChem 9, 2881 (2017)

H. Song, F.Y. Zhang, H.L. Song, X.W. Xu, F. Li, Catal. Commun. 69, 59 (2015)

Y.Y. Shu, S.T. Oyama, Carbon 43, 1517 (2005)

H. Loboué, C. Guillot-Deudon, A.F. Popa, A. Lafond, B. Rebours, C. Pichon, T. Cseri, G. Berhault, C. Geantet, Catal. Today 130, 63 (2008)

K.S. Cho, H.R. Seo, Y.K. Lee, Catal. Commun. 12, 470 (2011)

H. Song, M. Dai, H.L. Song, X. Wan, X.W. Xu, Z.S. Jin, J. Mol. Catal. A- Chem. 385, 149 (2014)

H. Song, M. Dai, H.L. Song, X. Wan, X.W. Xu, C.Y. Zhang, H.Y. Wang, Catal. Commun. 43, 151 (2014)

H. Song, M. Dai, H.L. Song, X.X.W. Xu, Appl. Catal. A 462–463, 247 (2013)

A.I. d’Aquino, S.J. Danforth, T.R. Clinkingbeard, B. Ilic, L. Pullan, M.A. Reynolds, B.D. Murray, M.E. Bussell, J. Catal. 335, 204 (2016)

A. Sawada, Y. Kanda, M. Sugioka, M. Uemichi, Catal. Commun. 56, 60 (2014)

H.I. Meléndez-Ortiz, L.A. García-Cerda, Y. Olivares-Maldonado, G. Castruita, J.A. Mercado-Silva, Y.A. Perera-Mercado, Ceram. Int. 38, 6353 (2012)

V. Teixeira da Silva, L.A. Sousa, R.M. Amorimb, L. Andrini, S.J.A. Figueroa, F.G. Requejo, F.C. Vicentini, J. Catal. 279, 88 (2011)

Z.Y. Pan, R.J. Wang, Z.Y. Nie, J.X. Chen, J. Energy Chem. 25, 418 (2016)

X. Wang, P. Clark, S.T. Oyama, J. Catal. 208, 321 (2002)

S.T. Oyama, X. Wang, Y.K. Lee, W.J. Chun, J. Catal. 221, 263 (2004)

S.T. Oyama, X. Wang, Y.K. Lee, K. Bando, F.G. Requejo, J. Catal. 210, 207 (2002)

K.A. Layman, M.E. Bussell, J. Phys. Chem. B 108, 10930 (2004)

I.K. Tamás, V. Zdeněk, G.P. Dilip, R. Ryong, S.K. Hei, J.M.H. Emiel, J. Catal. 253, 119 (2008)

J.N. Kuhn, N. Lakshminarayanan, U.S. Ozkan, J. Mol. Catal. A 282, 9 (2008)

L. Song, S. Zhang, Q. Wei, Catal. Commun. 12, 1157 (2011)

H. Song, M. Dai, Y.T. Guo, Y.J. Zhang, Fuel Proces. Technol. 96, 228 (2012)

P. Liu, J.A. Rodriguez, J. Am. Chem. Soc. 127, 14871 (2005)

H. Song, J. Wang, Z.D. Wang, H.L. Song, F. Li, Z.S. Jin, J. Catal. 311, 257 (2014)

S.T. Oyama, T. Gott, K. Asakura, S. Takakusagic, K. Miyazakib, Y. Koiked, K.K. Bando, J. Catal. 268, 209 (2009)

H. Song, X.W. Xu, M. Dai, H.L. Song, Chem. J. Chin. Univ. 34, 2609 (2013)

S.T. Oyama, Y.K. Lee, J. Catal. 258, 393 (2008)

R. Prins, M.E. Bussell, Catal. Lett. 142, 1413 (2012)

Acknowledgements

The authors acknowledge the financial supports from the National Natural Science Foundation of China (21276048).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Song, H., Zhang, F., Jiang, N. et al. Synthesis of an Ni2P catalyst supported on Na-MCM-41 with highly activity for dibenzothiophene HDS under mild conditions. Res Chem Intermed 44, 5285–5299 (2018). https://doi.org/10.1007/s11164-018-3423-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-018-3423-z