Abstract

Wastewater treatment plants (WWTPs) consume high amounts of energy which is mostly purchased from the grid. During the past years, many ongoing measures have taken place to analyze the possible solutions for both reducing the energy consumption and increasing the renewable energy production in the plants. This review contains all possible aspects which may assist to move towards energy neutrality in WWTPs. The sources of energy in wastewater were introduced and different indicators to express the energy consumption were discussed with examples of the operating WWTPs worldwide. Furthermore, the pathways for energy consumption reductions were reviewed including the operational strategies and the novel technological upgrades of the wastewater treatment processes. Then the methods of recovering the potential energy hidden in wastewater were described along with application of renewable energies in WWTPs. The available assessment methods, which may help in analyzing and comparing WWTPs in terms of energy and greenhouse gas emissions were introduced. Eventually, successful case studies on energy self-sufficiency of WWTPs were listed and the innovative projects in this area were presented.

Similar content being viewed by others

1 Introduction

Water-energy nexus is one of the crucial elements for human sustainable development (Jiang et al. 2016; Chen and Chen 2016). These two resources are essential for global production and life (Walker et al. 2013). Wastewater treatment plants (WWTPs) are central to water-energy interactions (Xu et al. 2017) as the plants consume energy to remove pollutants and thus reduce human footprint on the natural water environment (Gu et al. 2016). On the other hand, if energy delivered to WWTPs from external grid originates from fossil fuel incineration, greenhouse gases (GHG) emission is induced while increasing the global warming potential (GWP). To tackle the problem, major economies in the world have implemented a policy on energy saving. The wastewater treatment industry, being one of the main energy consumers, has developed various technologies to improve the energy efficiency (Ho et al. 2014), but in practice, there is no single recommended scenario for the energy self-sufficiency. Energy often represents the second largest operational cost behind labour for providing wastewater services to the public (Lindtner et al. 2008; Wojtowicz et al. 2013; Moss et al. 2013). Therefore, increasing the energy efficiency is one of the most effective ways for WWTPs to manage costs and help ensure the long-term operational sustainability (WERF 2015a).

As nutrient limits continue to ratchet downward and electricity costs creep upward, and with an increased focus on carbon footprint, climate change, and GHG emissions, all consumers are becoming more cognizant of the impacts of their activities on the social, environmental, and financial bottom lines. This triple bottom line approach also refers to the wastewater industry (Horne et al. 2013). According to a new paradigm in wastewater treatment, WWTPs should be designed considering maximization of the resource and energy recovery. This new approach emphasizes a shift towards the energy neutral or even energy positive facilities. Another challenge is decreasing the carbon footprint of WWTPs via reduction of direct and indirect GHG emissions. The direct emissions, such as N2O and CH4 from bioreactors and sewers, are often a large portion of a WWTP carbon footprint (Lorenzo-Toja et al. 2016; Schaubroeck et al. 2015). It was found that just 1% of denitrified nitrogen emitted as N2O would increase the carbon footprint of the WWTP by approximately 30% (de Haas and Hartly 2004). The contributions of N2O emission in the total WWTP carbon footprint were reported as high as 78% by Daelman et al. (2013) and 60% by Rodriguez-Caballero et al. (2015). On the other hand, Aboobakar et al. (2013) reported that N2O emission added only 13% to the carbon footprint associated with the energy requirements. Except for specific plant configurations and operational conditions, those differences can also be attributed to the assumed energy source. The share of indirect emissions mainly caused by electricity consumption, chemicals and transportation cannot be neglected when it comes to the total carbon footprint of WWTPs. Striving for sustainability in wastewater treatment, a complex and multi-criteria approach is essential, as well as expanding the system boundaries beyond the WWTP. Increasing the share of renewable energies for the off-site electricity production can also support the activities carried out within the WWTP.

In general, carbon neutrality in WWTPs is related to the term energy neutrality. Even though novel technological solutions are already available for achieving energy neutrality, their application to upgrade existing plants can be far more challenging than building new dedicated plants (Gao et al. 2014). Bertanza et al. (2018) adopted a detailed evaluation on the actual impacts of upgrading existing WWTPs and concluded that the energy self-sufficiency was not far away to be achieved, with moderate techno-economic implications, especially when the plant would be equipped with primary sedimentation and anaerobic digestion (AD). The regular energy monitoring is essential for identifying the potential for improvement. Marner et al. (2016) strongly suggested that energy audits should be performed regularly using a systematic procedure to obtain adequate knowledge of the energy consumption profile of a WWTP.

The energy neutrality can be approached via different methods but there are two crucial factors which must explicitly be analysed. First, the effluent standards for achieving the required quality of wastewater should be maintained. Secondly, the additional capital costs for modifying the existing instruments in WWTPs should be convincing for the plant operators. Therefore, ongoing investigations seek to improve the energy balance and optimize the relationship between energy and effluent quality.

When it comes to the energy neutrality in WWTPs, it is crucial to employ all the possibilities to cover the electricity consumption. Typically, the potential energy derived from sludge in various forms is not enough for energy self-sufficiency. Therefore, the production of renewable energy in the plant from the external sources appears to be a solution which can add the clean energy to the energy balance. By applying the renewable energies, a greater opportunity appears to move towards the energy neutrality of WWTPs.

The aim of this review is to present in a systematic way, the various approaches to achieve energy neutral conditions in WWTPs. The systematic review contains identification and quantification of the energy balance components, methods for reducing energy consumption and methods for increasing energy recovery, supplemented with options for gaining the external renewable energy resources. The recent case studies were reviewed and possible scenarios to improve the energy balance in WWTPs were introduced. Finally, examples of WWTPs striving for or already achieved energy neutrality are presented.

2 Energy considerations in WWTPs

2.1 Energy distribution in WWTPs

Wastewater contains a significant amount of chemical, thermal and hydrodynamic energy. The chemical energy is the energy bounded in organic molecules (expressed as the chemical oxygen demand—COD), and in some inorganic compounds (NH3), which can be released by exothermic reactions. Shizas and Bagley (2004) determined the energy content of organics in municipal wastewater, using a bomb calorimetry method. Results of those experiments revealed that the organic energy in wastewater is approximately 10 times greater than the electric energy required to treat it (Horne et al. 2013; Moss et al. 2013). On the contrary, Parry (2014) challenged this argument by showing that not all the potential energy can be used for energy neutrality or even positive effect in WWTPs due to low-grade heat that has low energy quality for production. Indeed, a very efficient operation is required to achieve the power positive effect in WWTPs. Products of energy recovered from wastewater include electricity, biogas, steam and hot water which have different qualities (Parry 2014). The estimated total energy embedded in wastewater was estimated as high as 9.7 kWh/m3, including 2.7 kWh/m3 (28%) of the extractable energy (Gude 2015a). The highest specific energy consumptions reported by WWTPs in most cases are below 1 kWh/m3 (Table 1) which is still far less than the reported potentially extractable energy content of wastewater.

Biosolids typically contain approximately 4–6 kWh/kg on a dry weight basis, which is similar to the energy content of low-grade coal (Stone et al. 2010). There are many opportunities to convert the chemical energy in solids to a useable form (heat or fuel) through biological or thermal processes (Moss et al. 2013). The share of compounds that can be utilized depends on the method of energetic or material exploitation by microorganisms in the AD process, microbial electrochemical process, microbial synthesis or microbial conversion.

Figure 1 shows the various sources of energy entering a typical (medium or large size) WWTP which consists of a primary clarifier, biological reactor and AD, along with sinks and transformations of energy in the facility. The chemical energy enters the WWTP with the raw wastewater influent. In addition to the influent, there are other external resources also entering the WWTPs seeking the energy neutrality. These external sources of energy are primarily in the form of solar or hydro energy harvested on-site and biogas produced from the external organic wastes co-digested with sewage sludges. Energy losses include the wasted chemical energy from biological treatment, energy loss in the form of sludge and biosolids and inefficiencies of energy conversion in devices i.e. in combined heat and power (CHP) plants. Surplus energy refers to the energy produced on-site which exceeds the consumption for wastewater and sludge treatment and used in the background facilities for air conditioning, heating, lighting, etc. The energy positive WWTP can export excess energy outside the plant. In this approach, energy neutrality refers to the state of the energy independency from final energy carriers (mainly electricity) produced outside and imported to the WWTP. In order to reach the energy neutrality various measures could be undertaken, including:

-

1.

Reducing the energy consumption in wastewater treatment processes,

-

2.

Increasing the energy recovery from internal sources,

-

3.

Adding sufficient external sources of renewable energy.

These measures are discussed further in the paper.

2.2 Energy consumption in WWTPs

A report prepared for the Electric Power Research Institute (EPRI) (Burton 1996) estimated that the energy demand for the combined water and wastewater industry would be approximately 75 billion kWh per year, or about 3% of the electricity consumed in the US at the time. After almost two decades another study in the US (Rothausen and Conway 2011) revealed that the wastewater treatment sector itself consumes approximately 21 billion kWh each year, which corresponds to the equivalent of 1.8 million typical households. Treatment and transport of wastewater currently consumes approximately 4% the total electrical power produced in the US (Xu et al. 2017). In Europe, WWTPs contribute to approximately 1% of the total electricity consumption in cities (Haslinger et al. 2016). Data from Germany and Italy show that the electricity demand for wastewater treatment accounts for approximately 1% of the total consumption in the countries, whereas another study revealed that WWTPs account for approximately 0.7% of the total energy consumption in Germany (Husmann 2009). In Spain, some studies suggest that domestic and industrial water cycles account for 2–3% of the total electric energy consumption. When considering water management and agricultural demand, the contribution could even reach 4–5% (Longo et al. 2016). It is estimated that the electricity required for wastewater treatment will increase by 20% in the next 15 years in the developed countries, leading to a significant increase in CO2 emissions and resource consumption (Yan et al. 2017).

Many factors influence the energy consumption for wastewater treatment. The energy demand depends on the plant location, plant size, type of a treatment process and aeration system employed, effluent quality requirements, age of a plant, and knowledge and skills of the operators. Although the average energy consumption per cubic meter of treated wastewater (kWh/m3) is in a narrow range across countries (Hernández-Sancho et al. 2011), the amount of energy needed for operations varies widely among individual WWTPs as shown in Table 1. The range of the reported data on the specific energy consumption can be as low as 0.25 kWh/m3 (Ho et al. 2014) for WWTPs using advanced biological removal systems with several energy conservative measures. The data on energy consumption could be over 1 kWh/m3 (Trojanowicz 2016; Gu et al. 2017) which is considered as a high amount according to the literature and might be caused for several factors, such as high load of industrial wastewater influent, stricter environmental limitations, complex technology, etc. The climate under which the WWTPs were operated, appeared to have a minor impact on energy consumption such that colder temperate conditions could possibly have resulted in lower energy consumption in comparison with tropical conditions. For example, the reported overall specific consumption in Canada and Singapore was 0.3 kWh/m3 and 0.45 kWh/m3, respectively (NEWRI 2009).

In another study in China, Li et al. (2017) investigated 22 WWTPs in Shenzhen and analysed the effect of treatment capacity and treatment technology on the energy cost per unit of wastewater treated. The results showed that the average energy consumption of the studied WWTPs was 0.20 ± 0.06 kWh/m3, which was significantly lower in comparison with some developed countries (Table 1). The lower specific energy consumption in WWTPs located in Shenzhen (China) might be related to 2 reasons. Firstly, most of the WWTPs under study were constructed in past 10 years and are more technologically advanced in comparison with the ones constructed 30 years ago in developed countries (Li et al. 2017). The second reason is that compared to the wastewater characteristics in European countries, COD in China’s municipal wastewater is quite low (typically between 200 and 400 mg/L while in European countries can be from 400 to 800 mg/L). As a consequence, less energy can be used for oxidation of organic compounds (Hao et al. 2015). Furthermore, the labour cost and electricity consumption covered about 30% and 26%, respectively, of the total economic cost in the three typical WWTPs in Shenzhen. Thus, upgrading treatment machines and equipment and improving management level are two effective alternatives to decrease energy consumption and lower the total economic cost of the WWTPs.

Before describing the methods and technologies for decreasing the energy consumption in wastewater treatment processes, the main energy consumers in WWTPs should be identified. Table 1 shows literature data on the share of main consumers in wastewater treatment. Regardless of the WWTP size, most of the energy is consumed during biological treatment (can be up to 75% of total consumption) (Rosso et al. 2008). As shown in Table 1, more than 60% of the listed WWTPs consume more than a half of their energy just for aeration in the biological state of the plant. Therefore, the most consistent energy savings in the treatment line can be achieved there. Another important contribution may derive from the optimization of primary settling efficiency and pumping operations provided that the necessary amount of biodegradable organic compounds to protect denitrification is guaranteed. More relevant options for the energy saving may be found in the sludge processing line, primarily by the optimization of AD and installation of CHP engines (Panepinto et al. 2016). Although aeration is the most well-known energy intensive operation as it can be seen in Table 1, recirculation of the settled sludge, and aerobic sludge stabilization may also have comparably high energy consumption, but those factors are often erroneously ignored in small WWTPs (Foladori et al. 2015).

2.3 Energy performance evaluation

As it was indicated in the previous section, the specific energy consumption and energy distribution in WWTPs depend on many factors and assumptions. Thus, uniform procedures are postulated to facilitate a comparison between the plants, as well as to diagnose the actual performance of a specific plant and evaluate upgrades under consideration. Information on energy consumption in various processes of wastewater treatment allows to focus on modifying the stages of a WWTP which are operated less efficiently (WERF 2011; Gu et al. 2017).

Energy audit is a preliminary procedure used to evaluate energy consumption in an object and identify energy conservation measures (ECMs). Energy audits in WWTPs reveal large differences in the energy consumption in the various stages, also depending on the indicators used in the audits. Formulating a uniform methodology to perform audits in WWTPs and identifying the most suitable key energy consumption indicators for comparison between different plants is necessary (Foladori et al. 2015). One of the aims of an energy audit is determination of an energy baseline regarding the reference consumption of individual devices and installations. Energy consumption data can be collected together with operational data, and influent and effluent characteristics, whereas major energy consuming devices, such as blowers, mixers, pumps and aeration systems must be found separately (Longo et al. 2016). Final recommendations refer to operational and process modifications leading to the energy savings.

Energy benchmarking is a powerful tool in the optimization of WWTPs, which can help reduce costs and GHG emissions. Traditionally, energy benchmarking methods focused solely on reporting electricity consumption, however, recent developments in this area have led to the inclusion of other types of energy, such as heat, chemical and mechanical consumptions, which can be expressed in kWh/m3 (Belloir et al. 2015). Following one of the published benchmarking protocols, a “standard” WWTP can be defined in order to compare energy usage in the plants with different characteristics.

Eco efficiency supports WWTPs on their way towards sustainability by focusing their efforts mainly on the reduction of energy consumption, improvement of processes, and valorisation or elimination of waste flows. Henriques and Catarino (2017) noted that the removal efficiency of pollutant loads was related to the energy consumption at each studied WWTP. The sustainable value indicator, relating the removal efficiency to the cost or energy consumed, was established and used for comparison between the target plants. The results of energy audits already carried out show that despite the capacity, each WWTP has potential for energy savings. Those savings can range from 20 up to 40% and in some specific cases even more (there are examples where even 75% were attained (Panepinto et al. 2016)). The treatment efficiency of WWTPs is generally measured in terms of the removal of total suspended solids (TSS) organic matter (COD and BOD5) and nutrients (ammonia). The treatment performance can be affected by the age of WWTPs. Castellet-Viciano et al. (2018) proved that due to the deterioration of the facilities, the efficiency of the treatment (specially for smaller WWTPs) decreases gradually. Apart from kWh/m3 (most common indicator to assess the energy performance of WWTPs), three energy key performance indicators (KPIs) were defined. The second most frequent indicator reported in the literature shows the electricity consumption in relation to the population equivalent (PE) per year (kWh/PEyear). Furthermore, a reference to the amount of pollutants removed from wastewater expresses the electricity consumption related to the removed loads of BOD5 (kWh/kgBODremoved) and COD (kWh/kgCODremoved). The most commonly reported KPIs are listed in Table 2.

The available data on this indicator ranges between 12 and 60 kWh/PE.year. The prospective ideal value of energy consumption changes in terms of the condition of WWTPs as well as countries regulations. For example, Marner et al. (2016) considered 16.6 kWh/PE.year as a target for Bochum-Ölbachtal WWTP in Germany.

On-line measurement data, available in many WWTPs, should theoretically enable to decrease the management response time by daily benchmarking. Limited available data from WWTPs are often a challenge, therefore, Torregrossa et al. (2016) proposed a methodology to perform a daily benchmark analysis under database limitations. The methodology was applied to the energy online system (EOS) which calculated a set of KPIs for the evaluation of energy and process performances. In the EOS, the energy KPIs took the pollutant load in order to enable the comparison between different plants. The EOS did not analyse the overall energy consumption but the specific energy consumption in terms of pollutant load. This approach enables a comparison of performances for plants with different loads or a single plant under different loading conditions.

The energy audits and energy benchmarking are fundamental tools in assessing energy consumption and energy conservation potential, including implementation of new processes and technologies. It is expected that the proposed upgrades are energy and cost efficient, while still maintaining the effluent discharge limits. As the wastewater treatment paradigm shifted towards sustainability, the environmental impact in a life cycle has become another challenge in a WWTP optimization. Thus, the advanced and complex methods supporting decision making in the energy-related aspects have been proposed for WWTPs (Table 3).

3 Methods for reducing energy consumption

Energy is most often among top three most expensive items in a wastewater utility’s operation and management budget. Reducing the purchased energy not only benefits lowering the potential costs, but also results in decreasing the carbon footprint and increasing the sustainability of the operations (Horne et al. 2013; Moss et al. 2013). Methods of minimizing the electricity consumption can be divided into two major categories. The first one focuses on the operational modifications applied at different sections of a WWTP, whereas the second method incorporates the innovative processes for wastewater treatment with less energy demand compared to the traditional technologies.

3.1 Energy conservative measures via operational strategies

The ECMs via operational strategies include upgrades related to mechanical devices and aeration systems as the significant components of a WWTP energy balance. The advanced improvements have been recognized and recommended for implementation in both existing and designed plants.

3.1.1 Mechanical devices

Pumping operations can be a significant energy consumer at WWTPs, being in many cases are the second one after aeration (Saghafi et al. 2016). Upgrading motors is a conventional ECM that has been practiced at WWTPs. (WEF 2009) estimates that electric motors can make up 90% of the electric energy consumption of mechanical devices in a WWTP. Since the pumping life cycle costs are dominated by the energy costs in comparison with the construction phase, it is always worth of paying close attention to pumps and renew or service them whenever an energy audit reveals increased operating costs (Jenkins and Wanner 2014).

The variable speed operation is often the most energy-efficient flow control method for pumping systems, as the pump performance can be adjusted to meet the process demand instead of adjusting additional hydraulic losses (Ahonen et al. 2014). Variable frequency drives (VFDs) offer a rapid return on investment with the payback time ranging from 6 months to 5 years (NYSERDA 2010). USDOE (2005) reported numerous successful applications of the VFDs with energy savings ranging from 70,000 kWh/year for smaller WWTPs up to 2,800,000 kWh/year for larger WWTPs. Since the technology is already well-established, the recent trend is to make the devices more communicative to walk towards entirely smart managed processes (Philipon 2015). However, if the VFDs are not selected and applied correctly, they can waste energy. Operating below 75% of the full load, the VFDs can have very low efficiencies. In general, such drives may not be effective when a large static head must be overcome or where the flow rates are approximately constant (WEF 2009).

Mechanical surface aerators vigorously agitate the wastewater, transferring oxygen from the air by increasing the water-atmosphere interface. Agitators can contribute to about 5–20% of the total energy consumption of a WWTP, which depends on the design capacity. Reduction in the power density and decrease in the daily operation time are the major methods to reduce agitator energy consumption (Füreder et al. 2017).

In terms of the energy consumption for aerating Boncescu and Robescu (2017) performed an experimental research on different type of aerations including mechanical surface aerators. Aeration of 416 m3 water volume surface aerators consumed 25 kW with 2.3% oxygenation efficiency while fine bubble aerators consumed 8.2 kW with 23% oxygenation efficiency. These results confirmed that mechanical aerators have lower energy efficiency, thus the mechanical aerators should undergo ECM methodologies to increase their efficiency. Füreder et al. (2017) claimed that under favourable conditions with respect to the tank volume, tank geometry, aeration and agitator position, mixing energy can be reduced below 24 Wh/(m3day).

Radial-flow low-speed mechanical aeration systems can provide higher aeration efficiency than high‐speed machines (WEF and ASCE 2010). As the influent load to the plant decreases in the evening, the dissolved oxygen (DO) concentration increases consequently, cycling aerators off during night‐time hours can be effective in reducing aeration energy (EPA 2010). A new development in mechanical aerators is the use of multiple impellers. Single impeller mechanical aerators are limited in their turn down due to the need to keep the contents of the bioreactor from settling. A dual impeller aerator (Eimco 2018) includes a lower impeller near the bottom of the bioreactor to augment the surface impeller. This provides the additional mixing energy near the floor of the bioreactor, permitting greater power turndown when a VFD is used and associated energy savings. The ECMs of mechanical devices are summarized in Table 4.

3.1.2 Advanced aeration control systems

Automated control of the aeration process is an important ECM that can save considerable amounts of energy by quickly adjusting to dynamic conditions within the reactor. The amount of oxygen required to maintain biological processes within the aeration basin is proportional to the influent organic and ammonia loadings. The oxygen demand for aeration, therefore, follows the same diurnal pattern, dipping in the middle of the night and peaking in the morning and evening. The ratio of the peak to minimum oxygen demand can typically be 2:1 (Cantwell 2009). It is postulated that reduction in the DO set points can provide significant energy savings due to a lower amount of energy required for aeration and this can also result in reduced GHG emissions (Mamais et al. 2015). On the other hand, over reduction of the DO set points may also lead to higher N2O yields which may override any energy-related GHG savings. Reconfiguration, replacement and application of the optimal DO control strategies for existing aeration systems in the facility and model-based DO optimization in WWTPs can result in the increased energy efficiency and savings and improved stability of the system (Pittoors et al. 2014).

A properly operating DO and aeration control system can save from 25 to 40% of the energy used by manually controlled systems. The DO control is commonly used to provide aeration savings by modulating airflow based on the oxygen demand and is a prerequisite for more advanced control strategies (Åmand et al. 2013). The recent availability of reliable ammonia, nitrate, and nitrite sensors has led to more advanced aeration control strategies including ammonia-based aeration control (ABAC) and Ammonia vs. Nitrate (AVN) control (Klaus 2016).

Intermittent aeration saves energy by reducing the number of hours when an aeration system is turned on. The cycle length can be controlled along with the DO concentration. For example the implementation of intermittent aeration in a pilot-scale system based on the modified Ludzack-Ettinger (MLE) process configuration significantly improved TN and TP removal and additionally saved aeration energy by 10% in comparison with the continuous aeration mode (Liu and Wang 2017).

Ammonia-based aeration control system

The most common aeration systems are controlled based on the DO measurements. However, keeping the DO levels constant as the ammonium concentration approaches zero could result in unnecessary aeration. This condition can be alleviated with the use of ABAC, which can reduce both aeration costs and peaks in the effluent ammonia concentration (Sadowski 2015).

There are two types of the ABAC structures, including feed-back and feed-forward (Fig. 2). The first approach is simpler and comprises the direct control of aeration based on the feed-back from the ammonium measurement in the aerobic zone. In a case study, a WWTP (250,000 PE, receiving 95,000 m3/day wastewater) used online ammonium ion selective electrode (ISE) measurement to ensure nitrification is complete. Blowers cycled on and off to maintain the ammonium-nitrogen concentration between the set points of 0.7 mg N/L and 1.0 mg N/L. The blowers were “off” 25% of the time with this strategy enabling anoxic conditions for denitrification and saving about $20,000 per month in the energy costs (Higgins 2016). Feed-back control is based on the measured output of the process and therefore a possible criticism is that an error must exist before a control action can be taken.

ABAC feed-back type system scheme (based on Higgins 2016)

The feed-forward aeration control is based on the upstream ammonium concentration and measurement of the disturbance (Smith 2013). It has greater complexity but offers the potential to achieve better effluent quality at a reduced energy cost (Rieger et al. 2014). Another case study on a WWTP located in Illinois (US) with the design average flow rate of 34,000 m3/day, showed that the airflow closely followed the upstream ammonium concentration and the DO concentration was maintained near 2.0 mgN/L for the majority of the time. This strategy achieved the lowest unit airflow demand, 11% lower than with the DO feed-back control (Poole 2012). On the other hand, Rieger (2012) noted that the benefit of feed-forward aeration control did not, in most cases, provide a substantial benefit over feed-back control and thus the additional cost and complexity were not justified. The advantage of feed-forward control is that the system reacts faster to a disturbance eliminating short-term effluent peaks and allowing a smoother control. In practice, however, predictions are only as good as the model on which they are based. Therefore, the feed-back from an effluent ammonium sensor is also recommended to correct errors in the model.

Ammonia versus nitrate control system

An intermittent aeration strategy termed ammonia versus nitrate (AVN) control (Fig. 3) has originally been developed to achieve nitrite shunt through nitrite oxidizing bacteria (NOB) suppression (Sadowski 2015). However, AVN control has the potential to be expanded beyond nitrite shunt and provide more efficient nitrogen removal than ABAC. By setting the effluent ammonia and NOx (NO3 + NO2) concentrations equal, or by specifying a ratio of NH4–N/NOx–N based on the actual need to comply with an effluent ammonia limit, AVN control oxidize only the amount of ammonia that can be denitrified utilizing the influent organic carbon. With this approach, COD utilization efficiency is maximized without the need of addition of supplemental carbon. This can be achieved with either continuous or intermittent aeration. For many existing WWTPs, intermittent aeration may be difficult to implement due to limitations of the existing aeration equipment (Regmi et al. 2014). A model-based evaluation revealed that the AVN aeration control method has a relatively better efficiency of nitrogen removal (17.5%) in comparison with ABAC. Furthermore, AVN control allows to consume 8.6% less oxygen compared to ABAC (WERF 2015b).

AVN control scheme (based on Regmi et al. 2015)

Bioprocess intelligent optimization system

The bioprocess intelligent optimization system (BIOS) is a comprehensive feed-forward optimization that performs simulation calculations based upon online measurements of temperature, ammonia, nitrate, and influent wastewater flow rate, integrating these process measurements with laboratory analytical results for mixed liquor suspended solids (MLSS) as inputs to the algorithm (Fig. 4). The BIOS simulation provides a continuous output of the DO set points for the biological treatment process based on the load entering the bioreactor (Olsson 2012). The BIOS control has the potential to minimize aeration energy consumption (Ho et al. 2014). Table 5 summarises various aeration control strategies which help reduce the energy consumption in WWTPs.

BIOS system scheme (Biochemtech 2018)

3.2 Energy savings via technological upgrades and processes (new pathways of nitrogen removal)

Transforming ammonia to nitrogen gas is an energy consuming process primarily because of high oxygen demand for nitrification. The alternative deammonification (termed also partial nitritation/anammox) process can achieve lower energy consumption. Partial nitritation/anammox is among the most innovative developments in WWTPs in terms of energy saving. The process can be compared with the conventional nitrogen removal in Fig. 5 (Soliman and Eldyasti 2016).

Comparison between a conventional nitrogen removal, b nitrite shunt and c deammonification in the nitrogen cycle (based on Soliman and Eldyasti 2016)

3.2.1 Nitrite shunt

The conventional biological nitrogen removal processes, such as nitrification–denitrification, require high amounts of oxygen (nitrification) and organic carbon (denitrification). To overcome the challenges and reduce the energy required for nitrogen removal, shortcut biological nitrogen removal (SBNR), called nitrite shunt, has been developed. In this process, the ammonia oxidation step stops at the nitrite stage, which is known as partial nitrification, then nitrite is reduced to nitrogen gas. Based on the fact that nitrite is an intermediate compound in both nitrification and denitrification, SBNR relies on the direct conversion of nitrite produced in the first step of nitrification to nitrogen gas instead of oxidizing nitrite to nitrate (Soliman and Eldyasti 2016). The nitrite shunt processes are operated to shunt the formation of nitrate by out-selecting nitrite oxidizing bacteria (NOB) (Miller et al. 2015). Several effective strategies for NOB suppression have been proposed, including especially tightly controlled operational DO concentrations, but also residual ammonia, transient anoxia, and controlled COD input, and short aerobic SRT (Gao et al. 2014; Cao et al. 2017; Feng et al. 2017).

SBNR implies the reduction of oxygen consumption during the aerobic phase by 25% as a result of skipping oxidation of nitrite to nitrate and consequently reduces the total energy required by 60%. Additionally, SBNR eliminates the use of electron donor (organic carbon) by 40%; resulting from skipping reduction of nitrate to nitrite; which makes it suitable for wastewater with low carbon to nitrogen ratio (such as sludge digester liquors). SBNR also results in a significant decrease in the sludge production in the nitrification denitrification processes by 35% and 55%, respectively. Coupled with nitrite-shunt and anammox it may be possible to approach energy neutral operation while meeting stringent nitrogen limits (Miller et al. 2015).

3.2.2 Anammox and deammonification

Ammonia-rich wastewater can be treated with the very economic autotrophic deammonification process, which requires no organic carbon source and less than half of the aeration energy compared to the conventional nitrification–denitrification (Siegrist et al. 2008). If organic carbon rich constituents are redirected to digester for biogas production, then insufficient organic carbon is remaining to remove nitrogen via conventional nitrification/denitrification, therefore partial nitritation/anammox process is encouraged for nitrogen removal (Seuntjens et al. 2018).

Anaerobic ammonium oxidation (anammox) is an autotrophic process for ammonium removal which was discovered in the mid-1990s and has widely been studied since then for its potential engineering application (Lackner et al. 2014). The anammox process requires less energy but anammox bacteria grow very slow (Kartal et al. 2010). The maximum growth rates of anammox bacteria (at 20 °C) were reported in the range of 0.019–0.08 and 0.13–0.14/day, respectively, for slow growing and fast growing species (Lu et al. 2018). For comparison, nitrifying bacteria (both AOB and NOB) have the maximum growth rates significantly higher (even > 2/day) (Cao et al. 2017).

Deammonification is a two-step process and the first step is the conversion of half ammonium to nitrite. The second step is the anammox process in which the remaining ammonium is oxidized to nitrogen gas by the produced nitrite. Both processes are autotrophic and can be performed in one-step sequencing batch reactors (SBR) system (Jenkins and Wanner 2014). More than 50% of all partial nitritation/anammox (PN/A) installations are SBRs, 88% of all plants being operated as single-stage systems, and 75% for side-stream treatment of municipal wastewater (Lackner et al. 2014).

Deammonification by ammonia oxidizing bacteria combined with anammox (Fig. 5c) provides up to 70–90% nitrogen removal with 65% reduction in aeration energy and 100% reduction in supplemental carbon compared to traditional nitrification–denitrification (Fig. 5a) (Gude 2015b). Jonasson (2007) reported that the total energy consumption of the Strass WWTP (Austria) was reduced by 12% after switching the previous nitrification/denitrification process with deammonification. The other benefit was that deammonification process did not require excess carbon which in the previous conventional denitrification led to higher volumes of excess sludge. Moreover, due to the enhanced recovery of readily digestible primary sludge, the methane content in biogas increased from 59 to 62%”. Kartal et al. (2010) compared conventional wastewater treatment and optimized treatment with anammox in a full-scale mainstream line based on energy consumption and production. By applying anammox in the mainstream line, the overal energy consumption was 17 kWh/PE.year while in the conventional treatment 30 kWh/PE.year was consumed (44% reduction in energy consumption by using the anammox technology). The optimized treatment with anammox also increased electric energy production from biogas by 12 kWh/PE.year (from 14 to 26 kWh/PE.year) which made the plant net energy positive (+9 kWh/PE.year).

4 Methods for increasing energy recovery

There are several types of technologies to recover energy throughout WWTPs. The recovered energy can be classified under three categories, including chemical, thermal and hydro energy.

4.1 Recovery of chemical energy

The calorific energy of wastewater is the energy content stored mainly in the various organic chemicals. In experimental studies, the energy content in untreated wastewater was estimated as 10–15 MJ/kg COD (~ 2.8–4.2 kWh/kg COD) (Shizas and Bagley 2004; Heidrich et al. 2011) and as low as 5.9 ± 3.4 MJ/kg COD (~ 1.6 ± 0.9 kWh/kg COD) (Korth et al. 2017) for the oven-dried samples. Based on the assumption of 12–15 MJ/kg COD, Tchobanoglous (2009) estimated the average calorific energy of about 1.5 kWh/m3 for wastewater with COD in the range of 250 mg COD/L to more than 1000 mg COD/L (which is common for domestic wastewater). Chemical energy from organic matter is converted into biomass energy during biochemical treatment (Zylstra and Kukor 2005). The recovery of chemical energy involves transformation of wastewater constituents into gaseous, liquid or solid fuels.

4.1.1 Anaerobic digestion

Biogas generated from sewage sludges in the mesophilic AD process is composed primarily of methane (60–67%) and carbon dioxide (30–40%), with small concentrations of nitrogen, hydrogen sulfide, and other constituents. The methane portion of the biogas is a valuable fuel and, with conditioning, can replace natural gas for many energy needs (Moss et al. 2013; Tyagi and Lo 2013; Bachmann 2015). By stoichiometry, the COD equivalent of methane can be determined as 0.35 m3 CH4/kg COD at standard conditions (0 °C), while the theoretical conversion factor at 35 °C is 0.4 m3 CH4/kg COD.

AD is more common in plants larger than 22,000 m3/day (Qi 2013) since in larger WWTPs it is more beneficial for plants operators to consider AD unit due to larger amounts of available sludge for digestion. Although AD is a mature technology (Moss et al. 2013; Gao et al. 2014) financial incentives in many European countries have led to a surge in AD installations to produce heat and electricity from biogas. Whiting and Azapagic (2014) studied the life cycle environmental impacts of a system producing biogas from agricultural wastes by AD and co-generating heat and electricity in a CHP plant. The results suggested that this can lead to significant reductions in most impacts compared to fossil-fuel alternatives, including the GWP which can be reduced by up to 50%.

An upgraded version of conventional AD is an anaerobic membrane bioreactor (AnMBR). In this technology, the reactor volume is considerably smaller which reduces the land footprint of conventional AD (Gao et al. 2014). Kanai et al. (2010) reported 65–80% reduction of the volume by using AnMBR bioreactor. Data given in the literature indicate that the available electrical energy produced in AnMBR systems ranges from 0.15 to 0.3 kWh/m3 as the wastewater strength increases from 240 to 1140 mgCOD/L (Martin et al. 2011). This amount is sufficient to recover a significant proportion of total energy consumption, and even offset the energy demand in some cases.

Table 6 shows the amount of biogas production (expressed in energy units) in various countries depending on the type of energy production as well as the share of WWTPs (sewage sludge) in the total net biogas production. On a country scale, a share of biogas production only from sewage sludge ranges from 7 to 49%, indicating that other biogas sources dominate in the overall balance. In Europe, Germany is a leading biogas producer (3050 GWh/year in WWTPs).

Biogas production through AD is limited to a conversion of the readily biodegradable portion of the solids contained in the sewage sludge. To overcome this limitation, and thus maximize biogas production, pretreatment processes and co-digestion have become rapidly growing practices in recent years (Moss et al. 2013).

4.1.2 Biogas utilization

The heating value of methane is approximately 10 kWh/m3 (at 25 °C). If the methane content of the biogas is assumed 65% by volume, consequently the heating value of the biogas produced in WWTPs can be estimated at 6.5 kWh/m3. The most readily adaptable approach to reduce external energy requirements with existing treatment plants is to make the full use of CH4 produced from conventional AD through cogeneration in CHP systems (McCarty et al. 2011; Lee et al. 2017). The USEPA (Bastian et al. 2011) estimated that if 544 WWTPs in the US employing AD, adapted CHP, the energy reduction would be equivalent to removing the emissions of approximately 430,000 cars.

The CHP systems are a justified choice if heat consumers are located in the vicinity of the plant. However, this requirement cannot be met in most of the cases. As a result, the excess heat energy must be vented to the atmosphere, which lowers the overall energy production efficiency and requires additional electrical power. The biogas upgrading to the quality of natural gas avoids this energy loss. The upgraded biogas in the form of natural gas substitute can be injected into the existing natural gas grids or used as a vehicle fuel using the natural gas infrastructure. The upgraded biogas can be distributed with a low cost to consumers, who can utilize it with a higher efficiency (Makaruk et al. 2010).

Beil et al. (2009) reported that at the time there were about 80 biogas upgrading plants in operation in Europe. They delivered the power of 200 MW (heating value related) which corresponded roughly to 170 million standard m3 of natural gas substitute. The total capacity of the biogas processing plants still seems to be relatively small in comparison to CHP plants.

The market of the biogas upgrading technologies is still poorly developed. The majority of those technologies derive from other gas separation technologies, mainly from the natural gas treatment (Makaruk et al. 2010). Furthermore, the membrane gas separation is a process that scales down very well. As reported by Baker and Lokhandwala (2008), the membrane gas separation is advantageous from the economic point of view if the gas volume flow is relatively low and the inlet CO2 content is relatively high. These parameters fit very well to a typical biogas upgrading task (Beil et al. 2009), and the CO2 content usually exceeds 30%. The gas permeation technology is a well-developed membrane separation process based on the sorption–diffusion mechanism using dense membranes (Cerveira et al. 2018). If the upgraded biogas is to be supplied to the gas grid under pressure, the gas permeation technology should gain advantage over upgrading technologies that operate at the atmospheric pressure since it uses the compression for both upgrading and grid injection.

4.1.3 Chemically enhanced primary treatment (CEPT)

Primary sludge from wastewater treatment is rich in organic compounds that can be resource for energy recovery (Lin et al. 2018). Chemically enhanced primary treatment (CEPT) enhances the primary settling and allows faster coagulation of particles in wastewater. This helps the formed larger conglomerates settle faster and make the removal process more efficient (Grigg 2005). Primary sludge tanks removal efficiencies vary in the range of 40–60 and 25–40% for TSS and COD, respectively. By adding chemicals these efficiencies can be enhanced to about 80–90% for TSS and from 50 to 70% for COD removal (Jenkins and Wanner 2014). Table 7 provides the removal rates and sludge production for various treatment types with and without chemical usage. One of the advantages of CEPT is the primary clarifier can be designed in a smaller size (even up to 50%) while treating the same amount of wastewater which translates to capital cost savings (Bourke 2000). Another benefit is decreasing energy consumption for the subsequent organic removal by approximately 50% due to the reduction in aeration needs (McCarty et al. 2011). Furthermore, more COD can be directed to AD for increased biogas production (Gori et al. 2013; Remy et al. 2014; Kooijman et al. 2017).

Lin et al. (2017) developed a new FeCl3-based CEPT for improved nutrient removal and energy recovery. By using CEPT, approximately 27% of the organic carbon in the influent wastewater could be recovered via sludge fermentation, mainly in the form of volatile fatty acids. For comparison, in the case of conventional primary sedimentation, the organic recovery ratio is under 10% (Lin et al. 2017).

A straightforward way to increase sludge production in WWTPs is CEPT with iron and aluminum coagulants but the overall energy recovery potential of CEPT may be unsatisfactory if the wastewater has a large fraction of dissolved organics. It should be noted, however, that some commonly used chemicals in CEPT have been reported to inhibit biogas production during AD (Meerburg et al. 2016). For example, aluminium inhibits the specific methanogenic activity (SMA) of methanogenic and acetogenic bacteria resulting in a 50–72% decrease in their activities (Cabirol et al. 2003). Al-based coagulants are characterized by rather low biodegradability due to the agglomeration of solid matters by the coagulant. Lin et al. (2018) studied on alkali pre-treatments by three chemicals, including NaHCO3, Na2CO3 and NaOH. The chemicals were applied to disintegrate Al-based sludge sedimentation (Al-sludge). The alkali pre-treatment significantly reduced the Al-sludge particle size (25% by average) and the yield of volatile fatty acids (VFAs) of the Al-sludge pre-treated by Na2CO3 was improved by 4 times compared to the un-treated sludge.

Ayoub et al. (2017) proposed utilization of the recovered alum from water treatment sludge as a coagulant and performed a comparative analysis with fresh alum. Table 7 shows the reported effects of CEPT treatment according to various methods found in different references in the literature. When comparing the recovered alum and fresh alum as coagulants, although a slight difference is observed but recovered alum is significantly better than the fresh alum in terms of the environmental impact.

4.1.4 Sludge pre-treatment

Degradation of the organic sludge fraction by the conventional AD is limited by the hydrolysis step. Degrees of volatile solids degradation higher than 50% are rarely achieved. This limitation results from the difficulty to access and degrade bacterial cells of the waste activated sludge (WAS) (Spinosa et al. 2011; Tyagi and Lo 2013; Ho et al. 2014). This deficiency can be overcome by applying the physical, chemical, thermal or mechanical pre-treatment step.

Pre-treatment processes break the bacterial cells and release the cell contents, making them available to the anaerobic bacteria for conversion to biogas. This increases the volatile solids reduction achieved in AD and consequently increases the biogas production by 20–50% depending on the technology used (Moss et al. 2013).

Thermal hydrolysis process

Thermal hydrolysis involves injecting steam at high temperature and pressure to rupture bacterial cells and improve the conversion of organic matter to biogas in the AD process. It is considered as a well-established technology for sludge pre-treatment but simultaneously a very complex process which has not commonly been adopted in practice (Moss et al. 2013). Based on the thermal hydrolysis process (THP) experience in Europe, biogas production can possibly be increased by 20–30% (Moss et al. 2013).

Additionally, the THP decreases the sludge retention time (5–7 days less than in the conventional digestion) and reduces the final volume of dewatered sludge by 40% (Menco 2012). Dewaterability tests carried out after THP process showed an increase in the dewaterability reducing the water content to 50–60% (Wang et al. 2010).

The first full-scale application of THP in north America in DC Water’s Blue Plains Advanced WWTP (1,400,000 m3/day) showed the biogas from the digestion process downstream of thermal hydrolysis would produce 10 MW net energy, meeting nearly half of the total power demand of the plant (Willis et al. 2012).

The pre-treatment by high pressure thermal hydrolysis (HPTH) was shown to aid WAS fermentation. Compared to fermentation of raw WAS, the pre-treatment enabled 2–5 times increase in the VFA yield and 4–6 times increase in the VFA production rate (Morgan-Sagastume et al. 2011).

A key factor regarding thermal hydrolysis pre-treatment is minimizing of the energy requirement needed to reach the reaction temperature. Sludge composition highly influences the net energy (i.e. energy generated minus energy required for steam production). The ratio of primary sludge to WAS highly affects the energy benefit. For example, in the case of less than 10% primary sludge, the net energy was reported negative (Barber 2016). The energy balance improves with increasing quantities of biodegradable primary sludge. In general, depending on the factors, such as sludge composition and thermal hydrolysis reaction temperature, the net energy benefit of this technology over conventional AD was found modest. To achieve the highest net energy, actions such as: reducing thermal hydrolysis temperature and using the optimal proportion of sludge composition (30% primary sludge, 70% activated sludge) must be undertaken. The optimal net energy was reported by Barber (2016) as high as 160 kWh/tDShyrolyssed.

Chemical pre-treatment

Free nitrous acid (FNA) is a low cost and renewable chemical that can be produced on-site from the AD liquor by nitritation. Pre-treatment of full-scale WAS with FNA (1.8 mg N/L concentration) can enhance the biodegradability of WAS and increase the methane production by 16% (Wei et al. 2018). Similar to FNA, free ammonia (FA) pre-treatment also enhances the methane production from WAS. The highest improvement in biochemical methane potential (22%) was achieved at 420–680 mg N/L FA concentrations (Wei et al. 2017). To improve the biochemical methane potentials to higher rates, Liu et al. (2018) suggested combination of FA and heat pre-treatments (150 mg N/L of FA concentration and 70 °C temperature). As a consequence, the biochemical methane potential was improved by approximately 25%.

Ultrasound and microwave disintegration

Ultrasound causes disintegration of the sludge floc structure and release of exoenzymes even with small energy inputs. This also creates more interfaces between the solid and liquid phase and therefore facilitates the enzymatic attack of the active microorganisms (Jordan 2018). The use of ultrasound for wastewater treatment has been shown to be technically feasible by numerous reports in the literature over the years (Mahamuni and Adewuyi 2010). There are several full-scale installations of the technology in Europe (Moss et al. 2013). Two sonication tests in the US plants showed inconsistent results (8% vs. 50% increase in the biogas production) (Gary et al. 2007).

The possibility to couple ozonation with ultrasonic cavitation, can give many simultaneous advantages, since ozone is a powerful oxidizing agent (Tyagi and Lo 2011). Xu et al. (2010) reported that soluble COD was increased from 83 to 2483 mg/L after 60 min of ozone treatment followed by 60 min ultrasound treatment (energy input 0.26 W/mL), and the soluble COD concentration increased up to 3040 mg/L after 60 min ultrasound/ozone treatment.

Microwave irradiation is associated with electromagnetic radiation in the frequency range of 300 MHz-300 GHz. Due to high water content, sewage sludge absorbs the microwave irradiation. In principle, microwave is focused on directing heat rapidly, which lowers the energy losses while transmitting energy (traditional heating). A uniform microwave field generates energy through the realignment of dipoles with oscillating electric fields to generate heat both internally and at the surface of the treated material (Tyagi and Lo 2011).

Most of the research on disintegration methods of WAS is focused on technological effects of sludge pre-treatment. Therefore, Skorkowski et al. (2018) analyzed the specific effectiveness of ultrasound disintegration (g SCOD/Wh). The indicators of efficiency showed 4.08 mg O2/Wh for the energy density applied as high as 80 Wh/L, which is relatively low in comparison with other disintegration methods. Therefore, Skorkowski et al. (2018) suggested the hybrid sludge pre-treatments, such as pre-mixing and sonication combined to achieve higher energy efficiencies (5.83 times higher pre-treatment efficiency was reported).

Hydrodynamic disintegration

The appearance of vapor cavities inside an initially homogeneous liquid medium, occurs in very different situations. Cavitation can be defined as the breakdown of a liquid medium under very low pressures (Dular et al. 2016). Extreme pressures and temperatures from cavitation collapses to disintegrate smaller organic molecules, which are hard to be disintegrated using conventional biological methods (Suslick et al. 2011). Also new applications of hydrodynamic cavitation are beginning to emerge in other fields such as enhancing biogas production from WAS (Dular et al. 2016).

Żubrowska-Sudoł et al. (2017) showed that with the increase in energy consumed in disintegration, the increased amounts of organic compounds were released from the sludge. It was also documented that the introduction of WAS disintegration prior to the fermentation tank, resulted in 33.9% increase in the biogas production (Moss et al. 2013). The increased amount of biogas produced corresponded to the chemical energy in the amount of approximately 5200 kWh/day. Considering the average efficiency of the engine for converting chemical to electrical energy is about 40% then 2080 kWh/day of energy is produced. On the other hand, the energy consumed for disintegration in the studied WWTP was significantly lower (480 kWh/day). This rough estimation showed a positive net balance which makes this sludge pre-treatment a promising technology to be adopted in WWTPs.

4.1.5 Bioelectrochemical systems

Bio-electrochemical systems (BESs), such as microbial fuel cells (MFCs) and microbial electrolysis cell (MECs) (Fig. 6), are generally regarded as a promising future technology for the production of energy from organic material present in wastewater. BESs are aimed at bio-energy generation in the form of methane and bio-hydrogen while treating wastewater in an anodic chamber. The potential of BES to produce intermittent chemicals and high-value derivatives has immensely been explored since last decade by adopting modified reaction kinetics (Jadhav et al. 2017). The MFC is capable of converting the chemical energy of dissolved organic materials directly into electrical energy, while MEC is capable of generating a product (e.g. hydrogen) from dissolved organic materials and that drives the reactions with an electrical energy input.

Bioelectrochemical wastewater treatment is based on the use of electrochemically active microorganisms (Rabaey et al. 2007). In the MEC, electrochemically active bacteria oxidize organic matter and generate CO2, electrons and protons. The bacteria transfer the electrons to the anode and the protons are released to the solution. The electrons then travel through a wire to the cathode and combine with the free protons in solution. MECs require relatively low energy input (0.2–0.8 V) compared to the typical water electrolysis (1.23–1.8 V) (Kadier et al. 2016). MFCs use an active microorganism as a biocatalyst in an anaerobic anode compartment for production of bioelectricity (Rahimnejad et al. 2015).

The current densities that can be generated with laboratory BES now approach levels that come close to the requirements for practical applications. Results of lab-scale experiments showed the removal rates as high as around 7 kg COD/m3 reactor volume/day of wastewater which is in the same range as conventional activated sludge systems (Rozendal et al. 2008). However, when it comes to working with industrial wastewater or natural environments, the implementation of BES is more challenging (Santoro et al. 2017). A further challenge is related to the low energy produced by MFCs (experimentally observed open circuit voltage is only around 0.7 − 0.8 V), which is currently orders of magnitude lower compared to chemical fuel cells (Wang et al. 2015).

Laboratory tests conducted for wastewater treatment by MEC through a broad range of mesophilic and psychrophilic temperatures (5–23 °C) using synthetic wastewater showed a COD removal efficiency of 90–97%. An electricity consumption of 0.6 kWh/kg of COD removed was observed. The low energy consumption coupled with enhanced methane production (at the same reactor in different phase of performance) led to a net positive energy balance in the bioelectrochemical treatment system which would be mostly suitable for small and remote communities due to reduced capital costs (Tartakovsky et al. 2017).

4.1.6 Coupled aerobic-anoxic nitrous decomposition oxidation process

The direct energy recovery from waste nitrogen has recently proven feasible using the coupled aerobic-anoxic nitrous decomposition (CANDO) process (Scherson et al. 2013). The chemical energy of nitrogen compounds can be estimated to approximately 0.3 kWh/m3 of wastewater (Horstmeyer et al. 2017). This energy can be recovered from nitrogenous oxygen demand (NOD) bound in reactive forms of nitrogen if the nitrogen can be removed from wastewater and processed to generate heat or electricity. Ammonia and nitrous oxide are two N species found in wastewater that meet these criteria (WERF 2011). The CANDO process consists of three steps: first, ammonium oxidation to nitrite; second is reduction of nitrite to N2O; and eventually, N2O conversion to N2 with energy generation (Scherson et al. 2014; Gao et al. 2017). The CANDO process converts reactive N to N2O, then captures the gas and recovers energy from it by using it as a co-oxidant in CH4 combustion or decomposing N2O over a metal oxide catalyst. The end product would be N2. The amount of released energy from 1 mol of ammonia in the CANDO process is 41 kJ (2.4 kJ/g NH3) (Fig. 7) (Gao et al. 2014).

CANDO process scheme (Gao et al. 2014)

CANDO’s first application in real wastewater feed streams was reported by Weißbach et al. (2018) to investigate the performance and dynamics of nitrogen removal and N2O production. A 93% conversion of ammonium to nitrite could be maintained for adapted seed sludge in the first step of nitrification (nitritation). The nitrous denitritation stage, inoculated with conventional activated sludge, achieved a conversion of 70% of nitrite to nitrous oxide.

4.1.7 Micro algae system

Microalgae can grow in wastewater and can play the dual role of bioremediation of wastewater treatment and generation of biomass for biodiesel production (Kligerman and Bouwer 2015; Raheem et al. 2018). One of the possibilities of obtaining renewable energy from microalgae is biogas production using AD (Sialve et al. 2009; Santos-Ballardo et al. 2016). Integrated approaches to wastewater treatment with algal cultivation systems are viable alternatives for sustainable energy recovery from wastewater (Gude 2015a).

Microalgae cultures offer a solution to tertiary and quandary treatments due to their ability to use inorganic nitrogen and phosphorus for their growth; and capacity to remove heavy metals, and some toxic organic compounds (Abdel-Raouf et al. 2012). The integration of microalgae-based biofuel and by-product production during wastewater treatment has major advantages for both industries (Christenson and Sims 2011). Methane can be generated from digestion of either algal biomass or the algae residue that is a by-product of lipid extraction for biodiesel production (Zamalloa et al. 2011). It has even been suggested that methane production from microalgae without lipid extraction is energetically more favorable than a system whereby the lipids are extracted prior to digestion, if the algal lipid content is less than 40% (Sialve et al. 2009). The methane yield from digestion of algae is typically much lower than the theoretical potential. High pressure thermal hydrolysis (HPTH) is shown to enhance methane yield during algae digestion by approximately 80% (13 L CH4/g VS). (Keymer et al. 2013).

Algal biofuels are still not commercially viable at the current fossil fuel prices. However, a niche opportunity may exist where algae are grown as a by-product of high rate algal ponds (HRAPs) operated for wastewater treatment (Park et al. 2011). Results of the study of Arashiro et al. (2018) to assess the HRAPs where micro algae is valorised for energy recovery, showed the annual average of 0.54 kWh/m3 of wastewater, electricity production from biogas cogeneration. Another way of energy recovery is the microalgae-MFC. It was reported that algae acted as an electron acceptor and were able to grow using CO2 generated at the cathode (Raheem et al. 2018). An algae biofilm MFC was established by Yang et al. (2018) to facilitate the nutrient removal and bioenergy generation. It was proved that the algae biofilm MFC system was able to handle wastewater in the continuous flow trials and the total net energy of 0.094 kWh/m3 of wastewater was obtained in the process.

Microalgae treatment has an advantage over the partial nitritation/anammox treatments with respect to aeration energy, but not with the land requirements. The results from a case study in Thailand showed 0.15 and 0.18 kWh/m3 total specific energy consumption for microalgae and partial nitritation/anammox configurations respectively. Also, microalgae treatment is not applicable in climates with the limited light availability, low temperature and low irradiance in the winter period. However, microalgae treatment may still be applicable in regions with a tropical climate (Khiewwijit et al. 2018).

Methane production by the AD of seaweed is restricted by the slow degradation caused by the influence of the rigid algal cell wall. Zou et al. (2018) presented the novel method based on rumen fluid pre-treatment. Rumen fluid improved fermentation and degradation of the microalgae biomass. The biochemical methane potential tests were performed to investigate the biogas production increase. After the suggested pre-treatment the biochemical methane potential increased by more than 30% for various scenarios.

4.2 Recovery of thermal energy

In WWTPs, thermal energy is controlled by the temperature of the influent wastewater. Heat can be recovered via various technologies (Moss et al. 2013). It can be harvested using a heat pump. For every 10 K temperature difference in wastewater, the thermal energy available would be 41.9 MJ/m3 (Gude 2015b). Another research by Hao et al. (2015) claimed that water source heat pumps could supply a net electrical equivalency of 0.26 kWh when 1 m3 of the effluent is cooled down by 1 K. The US Department of Energy (DOE) estimated that about 235 billion kWh of thermal energy in the form of waste hot water is discarded into sewer systems (Tomlinson 2005). Thermal energy from wastewater can provide heating and cooling to districts where there is enough demand for thermal energy. Compared with other traditional sources for heat pumps (e.g., groundwater, geothermal heat, or outdoor air), wastewater (grey water) exhibits a relatively high temperature because it originates from warm sources, such as dishwashers, showers, and industrial plants. The wastewater heat can be further used for applications such as low-temperature sludge drying (Chae and Kang 2013). The Austrian implementation of the European Directive 2012/27/EU on energy efficiency explicitly names heat recovery from wastewater as a measure to reduce final energy consumption and in few countries such as Switzerland and Germany, this energy source is already included in energy policy making (Neugebauer et al. 2015).

Wastewater heat recovery via heat exchangers and heat pumps constitutes an environmentally friendly, approved and economically competitive, but often underestimated technology. For instance, in Austria, this methodology might reduce up to 17% of the Austrian (GWP) of room heating (Culha et al. 2015). The main sewer in all larger towns supply sufficient waste water as source of energy, which can also be used by the retrofit of sewer heat exchangers as a heat source for large size heat pumps. The usage is especially economical, with more than 10,000 PE sized WWTPs. The sewer should have more than 0.8 meters in diameter and the heat users have to be located in the surrounding area. A maximum distance of 200 meters is given for small heat capacities, whereas the heat pump or the users can be located up to 2 km away from the sewer with higher capacities (OCHSNER 2012). One of the applications is reported in Canada (Gude 2015b), the heat-pump system was applied in an energy centre integrated with a municipal wastewater pumping station. The heat-pump system provided 3.5 MW energy output which was higher than 2.7 MW as initially planned.

4.3 Recovery of hydro energy

Hydropower generation in wastewater infrastructure is relatively new, with the earliest examples in research and in practice dating back only a few decades (Power et al. 2014). In comparison with chemical energy, recovery of hydro energy in WWTPs is less established with less literature available on this topic.

The effluent flow rate and the head pressure are two essential parameters in designing a hydropower plant. In WWTPs, the flow rate is affected seasonally by several factors and there are substantial variations in the flow rate. For example, in the Kiheung Respia WWTP (Korea), a low-head small hydro power plant at the discharge outfall generated a very small amount of energy (a contribution of < 1% to the energy demand of WWTPs). Nevertheless, the incorporation of a hydro power plant in WWTPs could still be attractive because it can be operated all year round (Chae and Kang 2013). A study done in the UK by Power et al. (2014) showed the potential for improvements in the sustainability of the sector through energy recovery using hydropower turbines at the outlets of WWTPs. Flow rates and head data in outlets were collected from over 100 plants in Ireland and the UK. An evaluation method was developed to determine the potential power outputs and payback periods of hydropower energy recovery schemes at the plants. The Kaplan turbine was found to have the greatest potential power output but the pump-as-turbine had the lowest cost per kilowatt. The electricity pricing was found to have the major impact on the economic viability of hydropower energy recovery (Power et al. 2014). Hydraulic energy recovery from effluent drops was undertaken at The Vienna WWTP, Austria. The treated wastewater is discharged in the amounts of 560,000 m3/day into Danube River with the elevation drop to Danube River from the plant outfall of 5 m. The electricity requirements for the plant operation were 480 kWh/year. The vertical axis turbine produced 1.5 Million kWh/year, used on site (2.6% of the WWTP demand) (Gude 2015b). In the case of Clark County WWTP, which treats about 680,000 m3/day, approximately 120 m effluent drop is available but the discharge point is 22 km far away. A 16 MW hydroelectric generating station produced over 85 Million kWh/year. The required pumping energy was approximately 4 Million kWh, and the remaining energy was supplied to a grid in the vicinity of the discharge point. The net present value (NPV) of this system was $0.06/kWh (Karafa et al. 2007).

Potential barriers for hydropower generation at the inlets and outlets of WWTPs include a lack of excess head, flow rate variations, turbine failure due to blockages or damage from particulates present in wastewater particularly in raw sewage at the plant inlets (McNabola et al. 2014). Gaius-obaseki (2010) suggested that it would not be economically viable to install a hydropower turbine unless the plant had a high flow rate or qualify for governmental incentives.

5 External sources of renewable energy

5.1 Solar energy

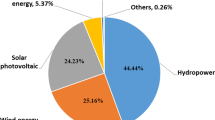

Photovoltaic (PV) panels provided only 0.1% of the total global electricity generation in 2010, however, it is projected to provide 5% of the global electricity consumption in 2030, rising to 11% in 2050. It was projected that by PV panels application, 2.3 Giga-tones of CO2 emissions will be avoided (Frankl and Nowak 2010).

Simulation results showed that a 96 kW PV system in the rooftop spaces could yield up to 150.7 MWh of electrical energy in a WWTP in south Korea. To maximize the energy production, the PV array needed to face the equator where the azimuth angle was 0. A hybrid type of PV system installed in the pre-existing building could produce 2% of the total energy demand. The economic analysis revealed that the tested technology was viable, with a payback time less than 7.4 years (Chae and Kang 2013). In another theoretical study, Xu et al. (2017) found that almost 80% of electricity consumption of a WWTP located in China could be produced only by PV using monocrystalline cells. If the WWTP adopted PV of nearly 9000 m2, it would be possible to supply most of the energy demand although the cost and land footprint should not be ignored. A report by Harper (2017) described a novel application of solar farm on the surface of an overflow pond at the East Lismore WWTP (Australia). This solar farm can produce 180,000 kWh of electricity per year which covers 12% of the total energy consumption of the plant. The main benefit of this project is the reduced land footprint. Furthermore, the cooling properties of water help increase the performance of the PV panels. The shade over the pond also prevents unwanted algal growth.

Another application of the solar energy in WWTPs comprises drying the sludge. The average electrical energy intensity in WWTPs in India is much lower (0.14 kWh/m3) in comparison with the UK (0.46 kWh/m3), due to solar heat is used in India for sludge drying (Singh et al. 2016). Another report by Colas (2017) explained a pilot system consisting of two parabolic solar concentrators used for sludge drying in Arizona (US). The collectors were able to generate heat power of 98 kW and dry sludge up to 90–97% solid content. That system is capable of producing 2 tons of sludge per day.

5.2 Organic waste co-digestion

The perspective of turning organic wastes into biogas has certainly increased the interest around this technology and required several studies aimed at developing methods that could improve both performance and efficiency of this process (Esposito et al. 2012). Due to the increased biogas yields, co-digestion of bio-wastes together with municipal wastewater can considerably reduce electricity purchase by WWTPs. Some successful examples from WWTPs have been reported in Denmark, Germany and Switzerland (Braun and Wellinger 2009). The examples are shown in Table 6.

In the US, food waste is the second largest category of municipal solid waste sent to landfills (over 30 million tons of food waste per year). With regard to energy independence, capturing the energy from food waste has become more important (Ho et al. 2014). The process of co-digestion can be performed by adding small amount of co-substrates which will not affect significantly the designed hydraulic retention time (HRT) (Maragkaki et al. 2018). The typical co-substrate addition rates in sludge digesters are between 5 and 20%. Addition of flotation sludge, fat trap-contents, food leftovers, proteinacious wastes etc. increases the biogas productivity considerably (i.e. by 40–200%). Nevertheless, if co-digestion is to be implemented into the existing WWTPs, depending on the bio-waste concentration and rheology, additional pre-treatment and post-treatment equipment may be required (Braun and Wellinger 2009). Koch et al. (2015) recommended co-digestion of raw sludge with food waste up to a ratio of 35% (based on the content of volatile solids). Co-digestion can result in both higher methane yield (due to a higher methane yield of food waste compared to raw sewage sludge), and in a higher methane production rate.

Recently, Mattioli et al. (2017) analyzed the effect of co-digestion of municipal solid waste and mixed sludge in Rovereto WWTP (Italy) (95,000 PE). It was shown that by treating 10,000 kg/day of organic waste, biogas generation increased from 1321 to 2723 m3/day which consequently doubled the power generation (from 3.9 to 7.8 MWh/day) and resulted in 85% recovery of the WWTP total energy demand. Food waste is more readily biodegradable than municipal wastewater solids (Gray and Suto 2008). Consequently, AD of food waste can be achieved at a shorter HRT (i.e. 5 or 10 days) in comparison with sewage sludge (min. 20 days in). In other words, the feed rate of food waste to ADs can be 2–3 times higher in comparison with sewage sludge. More importantly, food waste has higher specific energy content than sewage sludge. Food waste digestion results in a nearly 3 times higher biogas production rate in comparison with sludge digestion. Table 8 shows approximate organic waste biogas production yields. The results of about 175 biochemical methane potential assays indicate that substrates rich in lipids yield the highest methane potential (Labatut et al. 2011) followed by carbohydrates and proteins. On the other hand, high protein contents in co-digestion substrates may increase sulfure content in biogas and lead to engine corrosion. A potential contribution of adding food waste for self-sufficiency of WWTPs was investigated by Koch et al. (2016). The biogas production doubled with the addition of only 1000 m3 of food waste, while the amount of thickened raw sludge treated remained roughly the same at the level of 9000 m3. A comparison of 176 German WWTPs revealed that 44% of them achieved energy neutrality with a strong correlation to the fact that co-substrates were used.

Whiting and Azapagic (2014) studied the life cycle environmental impacts of a system producing biogas from agricultural wastes by AD and co-generating heat and electricity in a CHP plant. The results suggested that this can lead to significant reductions in most impacts compared to fossil-fuel alternatives, including the GWP which can be reduced by up to 50%.

Application of solar energy and organic waste co-digestion revealed the possibility of on-site electricity production, which in some WWTPs might cover partial or even all the energy consumption. In this review, according to the definition of energy neutral WWTPs provided in sub-chapter 2.1, renewable energy converted on-site and co-digestion help become independent from the external grid. However, an impact of these actions on the carbon footprint cannot be neglected.

6 Examples of case studies and projects on energy neutral/positive WWTPs

Currently, only a small subset of wastewater treatment facilities is operating in a manner that allows them to be considered totally or nearly energy neutral (Horne et al. 2013). Case studies which applied modifications to improve the energy balance are presented in Table 9.

6.1 Case studies on energy neutrality of WWTPs