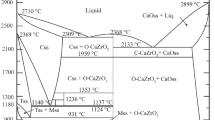

Data are provided for preparation of refractory materials and green semifinished products by melting zircon in an ÉDP-600M modernized electric-arc furnace. Melted and cast granular materials, and also materials with a reduced silica content are obtained.With respect to structure all of them are baddeleyite-silica, since they consist of baddeleyite and glass phase.

Similar content being viewed by others

References

L. Z. Bykhovskii, L. P. Tigunov, L. B. Zubkov, et al., “Russian zirconium and hafnium: contemporary state, recovery prospects and development of mineral raw material basis,” Mineral Syr’e, Ser. Geol.-Ekon., No. 23, 127 (2007).

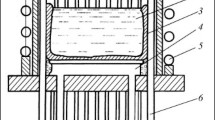

M. D. Gasparyan and V. A. Sokolov, “Industrial test unit ÉDP-600M for melting refractory oxide materials,” Coll. Sci.Work VI Internat. Sci.-Pract. Conf “Energy saving technology in industry. Furnace units. Ecology,” ITPE, NITU MISiS, Moscow (2006).

M. L. Thorpe and P. H. Wilks, “Electric-arc furnace turns zircon sand to zirconia,” Chem. Eng., 78(26), 117 – 119 (1971).

P. H. Wilks, “Arc-plasma dissociation of zircon,” Chem. Eng., 82(24), 56 – 57 (1975).

V. A. Sokolov, “Arc furnace assisted carbothermal decomposition of zircon,” Novye Ogneupory, No. 4,78 – 81 (2005); Refr. Indust. Ceram., 46(3), 208 – 211 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 5, pp. 8 – 10, May, 2014.

Rights and permissions

About this article

Cite this article

Sokolov, V.A. Melting Zircon in an Electric-Arc Furnace — A Method for Preparing Refractory Materials and Green Semifinished Products. Refract Ind Ceram 55, 191–193 (2014). https://doi.org/10.1007/s11148-014-9688-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-014-9688-x