Results are provided for preparation and properties of porous permeable ceramic with high values of open porosity and strength based on different grades of aluminum hydroxide powder. Part 1 of this article is devoted to studying properties of these powders.

Similar content being viewed by others

Introduction

Objects of porous permeable ceramic exhibit a number of advantages compared with the same objects made from porous metals, glass, and plastics. They have higher values of strength, stability in acid and alkali, molten ferrous and nonferrous metals, corrosive slags, and they may operate for a long time at high temperature. Therefore, currently objects of this ceramic are of considerable interest for users.

With respect to areas of application of porous permeable ceramic objects it is possible to separate several groups: group 1 is objects whose operating process is characterized by presence of excess gas or liquid pressure, which proceeds through pore channels, clean, homogenize, separate, and mix. These objects concern filtering elements for air cleaning from dust, water and oil mist, and also air and hot corrosive gases, for example blast and open-hearth furnaces, with temperatures up to 1000°C [1]; filtering elements for cleaning aerosols from gases, including radioactive materials [2]; filter elements for cleaning drinking water and effluent from industrial enterprises, electrolyte solutions, pulp, salt solutions, wine milk, acid, alkali, molten ferrous and nonferrous metals [3–5]; dispersers for finely-dispersed atomizing of gases in liquid media or melts, and also gaseous reagents in chemical reactors with the aim of increasing surface contact [6]; group 2 is objects of capillary-porous ceramic materials, whose operation is based on use of capillary pressure, arising at a liquid–gas interface. These objects concern evaporators, condensers, heating pipe wicks, capillary pumps, hydraulic valves, etc. [7]; groups 3 is objects of porous ceramic materials with special properties. for which during operation there is typically reaction of a pore surface with a phase previously introduced or passed through pore channels, which intensifies physical and chemical processes. The objects concern membranes for reference electrodes, bone tissue replacements, etc. [8].

Traditional methods for preparing porous permeable corundum ceramic, such as partial sintering (solid-phase) of narrow fraction alumina powders, liquid-phase sintering of narrow-fraction powders (using readily melting processing binders), with use of powders from materials with a non-cubic structure and with differing LTEC in the direction of the main crystallographic axes, using different pore formers, do not make it possible to obtain porous permeable materials with high (greater than 40%) values of open porosity [9]. It has been shown [10, 11] that introduction into the composition of aluminum oxide powder of an aluminum hydroxide additive makes it possible to obtain porous ceramic material with porosity values up to 50%, although the strength of these materials is quite low.

Aim of the Work

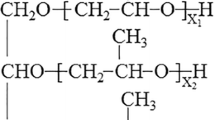

The aim of the work is preparation of porous permeable ceramic with high values of open porosity and strength of aluminum hydroxide powder with a study of its properties. In order to achieve this aim it was proposed to use aluminum hydroxide powder of different grades (having different morphology, phase, and grain size composition). Part 1 of this work is devoted to studying properties of these powders. The following powders were used:

-

aluminum hydroxide grade GD-12 (produced by OAO Boksitogorsk Alumina, TU 1711-001-00658716–99, prepared with decomposition of aluminate solution by carbonization in manufacture of alumina);

-

aluminum hydroxide grade MPK-1 (aluminum oxide hydrate of very fine chemically pure qualification produced by Donetsk Chemical Reagent Plant);

-

aluminum hydroxide MPK-2 (aluminum hydroxide grade TGA manufactured by Achinsk Alumina Plant);

-

aluminum hydroxide grade APYRAL 4 (density 2.4 g/cm3, specific surface 0.7 m2/g, produced by Nabaltec AG, Germany);

-

aluminum hydroxide grade APYRAL AOH 180E (density 3.0 g/cm3, specific surface 17 m2/g, produced by Nabaltec AG, Germany).

Hydroxides of all of the grades used are finely crystalline powders of white color. According to producer data material GD-12 contains 99.7 wt.% Al(OH)3 + 0.3 wt.% Na2O, material MPK-1 contains 99.4 wt.% Al(OH)3 + 0.6 wt.% Na2O, material APYRAL 4 contains 99.7 wt.% Al(OH)3 + 0.3 wt.% Na2O, and material APYRAL AOH 180E contains 99.7 wt.% Al(OH)3 + 0.3 wt.% Na2O. All of the materials used in the work are chemically pure.

Research Methods

Study of powder phase composition was performed in a Bruker D8 ADVANCE diffractometer from Bruker, Germany; morphology of the starting powders was studied by means of a JSM-6490 LV electron microscope from JEOL, Japan; grain size composition of powders was determined in an Analysette 22 particle laser analyzer from Fritsch, Germany; specific surface for starting materials was measured in an ASAP 2020 instrument from Micromeritics Instrument Corp, USA (low-temperature nitrogen absorption method); thermal analysis of powder specimens was carried out in a Paulik-Paulik-Erdey system Derivatograph Q-1500D instrument from MOM, Hungary.

Research Results

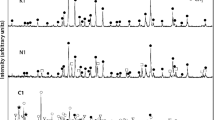

According to x-ray phase analysis data aluminum hydroxide grade GD-12 contains one phase of aluminum hydroxide Al(OH)3 with gibbsite modification with monoclinic elementary cell parameters a = 0.86735 nm, b = 0.507259 nm, c = 0.97268 nm, β = 94.552°. Specimen MPK-1 is a mixture of two modifications of aluminum hydroxide Al(OH)3: gibbsite with monoclinic elementary cell parameters a = 0.86831 nm, b = 0.50743 nm, c = 0.97175 nm, β = 94.428° and bayerite with monoclinic elementary cell parameters a = 0.5058 nm, b = 0.8698 nm, c = 0.47419 nm, β = 90.60°. According to quantitative x-ray phase analysis data by the Rietveld method a specimen contains 78.0 wt.% gibbsite and 22.0 % bayerite.

Specimens of NPK-2 and APYRAL 4 contain one phase of aluminum hydroxide Al(OH)3 with gibbsite modification of and specimen APYRAL AOH 180E contains one phase of aluminum oxyhydroxide AlO(OH) with boehmite modification. In x-ray patterns for specimens of MPK-2 and APYRAL AOH 180E quite high backgrounds were recorded, which is caused by a large amount of amorphous phase within them, particularly in specimen MPK-2. In contrast, the amorphous phase content in specimens of GD-12, MPK-1, and APYRAL 4 is not so great.

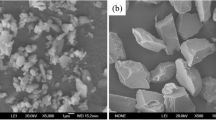

According to scanning electron microscope data specimen GD-12 consists of agglomerates of isotropic shape (close to spherical) represented by crystal accretions (Fig. 1a ). An electron microscope image was used to estimate the average agglomerate size (~52 μm) and average crystal size in agglomerates (~12 μm). Size distribution of agglomerates in a specimen of GD-12 is almost uniform within the range 5 – 20 μm. A specimen of NPK-1 consists of well faceted crystals of submicron size and large agglomerates of isotropic shape (Fig. 1b ). The shape of submicron crystals is identical to the form in a specimen of GD-12 (Fig. 1a ), from which it is possible to conclude that these crystals correspond to gibbsite modification, but agglomerates are a modification of bayerite. Within the structure of agglomerates of specimen of NPK-1 it is difficult to separate individually well faceted crystals, on contrast to a specimen of GD-12. The average size of agglomerates (~12 μm), and average size of crystals in agglomerates (~406 nm), were evaluated from electron microscope images. A specimen of NPK-1 has a monomodal distribution of agglomerates with respect to size in the range 5 – 30 μm. Size distribution of crystals in a specimen of NPK-1 is monomodal in the range 100 – 800 nm. A specimen of NPK-2 consists of crystals and large nonisometrically shaped large size agglomerates. A specimen of APYRAL 4 consists of crystals of nonisometric shape, similar to crystals of aluminum hydroxide grade NPK-2 (Fig. 1d ). and specimen of APYRAL AOH 180E consists of acicular crystals of nonisometric shape of submicron size (Fig. 1e ).

The grain size composition of aluminum hydroxide powders is given in Fig. 2. Results of determining the average diameter and specific surface of different grades of aluminum hydroxide are presented in Table 1. Results of studying grain size composition of powders and data for their specific surface confirm conclusions made on the basis of analyzing results of electron microscopy for the same hydroxide powders, i.e., powders have different morphology, size and structure.

Results of thermal analysis of hydroxide powders are shown in Fig. 3. The first endothermic effect on a thermogram for GD-12 material is observed at 80 – 200°C, and it is hardly accompanied by weight loss. This is connected with removal of physically bonded water (Fig. 3a ). The second and third endothermic effects, observed correspondingly at 220 – 280 and 300 – 400°C, are accompanied by significant weight loss and correspond to transformation of aluminum oxide trihydrates (gibbsite, bayerite) into monohydrate (boehmite); apparently transformation occurs in two stages. The fourth endothermic effect observed at 530 – 670°C is accompanied weight loss; it is not so significant as the second and third. This effect corresponds to transformation of boehmite into γ-Al2O3. There are also effects on a thermogram in the range 1010 – 1090°C, which may be connected with transformations of intermediate phases γ-Al2O3 into δ-Al2O3 and δ-Al2O3 into θ-Al2O3.

On a thermogram for NPK-1 material there is an endothermic effect at 90 – 180°C, hardly accompanied by weight loss, which is connected with removal physically bonded water (Fig. 3b ). The second and third endothermic effects were observed correspondingly at 245 – 280 and 300 – 420°C, accompanied by significant weight loss and correspond to transformation of aluminum oxide trihydrates (gibbsite, bayerite) into boehmite; the transformation apparently occurs in two stages. The fourth endothermic effect is observed at 530 – 620°C and is accompanied by weight loss; it is not as significant as the second and third. This effect corresponds to transformation of boehmite into γ-Al2O3.

The first endothermic effect on a aluminum hydroxide thermogram for grade NPK-2 is observed at 240 – 300°C and is accompanied by weight loss corresponding to transformation of aluminum oxide trihydrate into monohydrate (Fig. 3c ). The value of this thermal effect is significantly less than thermograms for GD-12, NPK-1, and APYRAL 4 hydroxides. Weight loss in this range is also insignificant. No second effect is observed in a thermogram corresponding to transformation of boehmite into γ-Al2O3. The difference in a thermogram for aluminum hydroxide grade NPK-2 from thermograms for powders of aluminum hydroxide grades GD-12, NPK-1, and APYRAL 4 may be explained by presence of a considerable amount of amorphous phase in this range.

In a thermogram for aluminum hydroxide grade APYRAL 4 the first endothermic effect is observed at 240 – 320°C (Fig. 3d ). This effect is accompanied by significant weight loss and is connected with transformation aluminum oxide trihydrate (gibbsite) into boehmite. The second endothermic effect is observed at 380 – 520°C and is accompanied by a small weight loss. This corresponds to transformation of boehmite into γ-Al2O3. For powder of aluminum hydroxide grade APYRAL AOH 180E at 300 – 500°C a peak is observed on a thermogram, and this is accompanied by a small weigtht loss and is connected with water removal with transformation of boehmite into γ-Al2O3 (Fig. 3e ).

Thus, the aluminum hydroxides selected for study differ both with respect to morphology and also phase and grain size composition. Summarized properties of aluminum hydroxide powders selected for study are presented in Table 2.

In view of the fact that aluminum hydroxide powders selected for study have different composition and properties, it may be suggested that in preparing ceramic (after sintering) the ceramic materials are obtained with different properties (different values of porosity). It is well known that a change in material porosity and density during firing may be connected not only with sintering of individual charge particles, but also with chemical reactions of their charge components. A procedure is proposed in [12] for evaluating volumetric changes of a molded specimen, occurring as a result of chemical reaction, and calculation of final specimen porosity. A criterion making it possible to evaluate reaction from this point of view of possible volumetric changes is the volumetric effect of reaction.

On heating aluminum oxide trihydrate (gibbsite, bayerite) it is transformed into boehmite, which during subsequent heating is transformed into aluminum oxide. Proceeding from the assumption that all of the materials used in this work consist solely of a crystalline phase, volumetric effects were calculated that will occur in high-temperature firing of specimens of different grades of aluminum hydroxide powder (Table 3).

Conclusion

Powders selected for study have different phase and grain size composition, morphology, and structure. Calculations showed that breakdown of aluminum hydroxide to aluminum oxide on heating is accompanied by an unfavorable volumetric effect, i.e., there is loosening of the structure and an increase in billet porosity. The volumetric effect of reaction for aluminum oxide monohydrate is less than for trihydrate, and in view of this it is possible to expect a lower value of porosity for specimens of hydroxide grade APYRAL AOH 180E compared with specimens of other grades of hydroxide.

Results concerning preparation and study of the properties of porous ceramic materials of different grades of aluminum hydroxide powders will be presented in part 2 of the articles.

References

B. L. Krasnyi, V. P. Tarasovskii, and A. Yu. Val’dberg, “Ceramic filters and their use for cleaning dust-laden hot exit gases,” Refr. Industr. Ceram., 46(2), 116 – 119 (2005).

B. L. Krasnyi, V. P. Tarasovskii, and A. B. Krasnyi, “Use of ceramic materials for resolving environmental problems,” Bezopas. Okruzh. Sredy, No. 1, 90 – 92 (2008).

B. L. Krasnyi, V. P. Tarasovskii, T. S. Marinina, and A. I. Goptar’, “Filter elements of high-quality quartz glass for continuous-flow silica-containing raw material enrichment equipment,” Steklo Keramika, No. 11, 5 – 6 (2006).

B. L. Krasnyi, V. P. Tarasovskii, and A. B. Krasnyi, “Development of porous permeable ceramic material and filtering element technology for candle-shaped filter equipment,” Refr. Industr. Ceram., 50(1), 22 – 25 (2009).

B. L. Krasnyi, V. P. Tarasovskii, and A. B. Krasnyi, “Development of ceramic material and filtering element technology for disk vacuum filtering units used in dewatering ferrous and nonferrous metal ore concentrates,” Refr. Industr. Ceram., 50(2), 107 – 111 (2009).

B. L. Krasnyi, V. P. Tarasovskii, A. B. Krasnyi, and A. M. Uss, “Porous permeable ceramic for fine bubble waste water aeration systems in aeration tanks,” Refr. Industr. Ceram., 51(5), 322 – 327 (2011).

Tsunedzi Nitta and Khiromitsu Toki, Japanese Patent 54-95611, Porous ceramic as wick for oil, Publ. 01.12.97.

S. A. Polyakov and S. A. Bel’mozhin, “Ceramic diaphragm for electrolysis processes,” Steklo Keramika, No. 11, 23 – 24 (1989).

B. L. Krasnyi, V. P. Tarasovskii, A. B. Krasnyi, and Ya. G. Mamytsin, “Effect of firing temperature on sintering and physicomechanical properties of porous permeable ceramic based on aluminosilicate binder,” Tekhnika Tekhnol. Silikatov, No. 1, 11 – 14 (2012).

Z. Deng, T. Fukasawa, and M. Ando, “High-Surface-Area alumina ceramics fabricated by the decomposition of Al(OH)3,” J. Amer. Ceram. Soc., 3(84), 485 – 491 (2001).

T. Ohji and Z. Deng, USA Patent 6565825 MPK B 2. Porous alumina fabrication procedures, Claimatns and patent holders T. Ohji and Z. Deng, No. 07/748019; Claim. 12.27.00; Publ. 05.20.03.

I. Ya. Guzman, Reaction Sintering and its Use in Refractory Technology [in Russian], RKhTU, Moscow (1996).

Work was carried out with financial support of the Ministry of Education and Science of the Russian Federation within the scope of state contract No. 16.552.7.7082, and on equipment of TsKP High-Tech Technology and Engineering.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 1, pp. 35 – 41, January 2014.

Rights and permissions

About this article

Cite this article

Krasnyi, B.L., Tarasovskii, V.P., Mosin, Y.M. et al. Porous Permeable Corundum Ceramic Based on Aluminum Powder. Part 1. Study of Different Grades of Aluminum Hydroxide Powder Properties. Refract Ind Ceram 55, 30–35 (2014). https://doi.org/10.1007/s11148-014-9653-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-014-9653-8