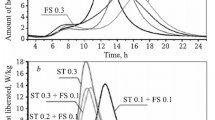

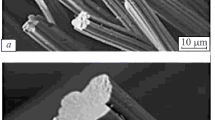

Comparative analysis is provided for the properties of medium-cement concrete based on mullite filler in relation to different type of deflocculant. The effect of different deflocculants on concrete structure formation, hydration, rheology, strength and heat resistance is discussed. It is proposed that in concrete with a composite deflocculant it is possible to form nano-structures as a result of which there is a considerable increase in concrete strength after drying at 110°C.

Similar content being viewed by others

References

H. Hommer and K.Wurtz, “Recent development in deflocculants for castables,” 9th BiennialWorldwide Congress on Refractories (2006).

J. Von Seyer, “Dispersant and fine aluminas: a new way to tailor flow setting time and strength development in castable mix designs,” Interceram. Refractories Manual, 36 – 47 (2005).

P. G. Vasilik, “New dispersants (deflocculants) for producing refractory concretes,” Novye Ogneupory, No. 8, 28 – 31 (2003).

S. Goberis, I. Pundene, and R. Stonis,” The influence of various plastisizers on hydration and physical-mechanical properties of refractory castable with chamotte aggregates,” Proc. 2005 XV Conf. on Refractory Castables, Prague (2005).

S. Goberis, I. Pundene, and V. Antonovich, “The effect of sodium triplyphosphate on the properties of medium-cement refractory castables based on Gorkal-40 cement,” Refractories and Industrial Ceramics, 46, No. 6, 403 – 408 (2005).

V. Antonovich, S. Goberis, and I. Pundene, “A new generation of deflocculants and microsilica used to modify the properties of conventional refractory based on a chamotte filler,” Refractories and Industrial Ceramics, 47, No. 3, 178 – 182 (2006).

S. Ostroj, M. Bahrever, and F. Mostarzadeh, “The effect of deflocculants on the self-flow characteristics of ultra low-cement castables in Al2O3 – SiC system,” Ceramic International., 31, No. 5, 647 – 653 (2005).

K. K. Strelov, Structure and Properties of Refractories [in Russian], Metallurgiya, Moscow (1982).

Author information

Authors and Affiliations

Additional information

Translated from Novye Ogneupory, No. 11 pp. 45 – 48, November 2009.

Proc. International Conference of Refractory Workers and Metallurgists (Moscow 23 – 24 April, 2009).

Rights and permissions

About this article

Cite this article

Pundene, I., Antonovich, V. & Stonis, R. Effect of composite deflocculant on the properties of medium-cement heat-resistant concrete. Refract Ind Ceram 50, 441–444 (2009). https://doi.org/10.1007/s11148-010-9234-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-010-9234-4