Abstract

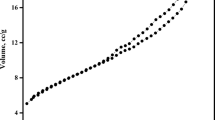

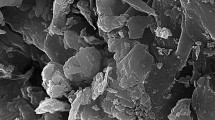

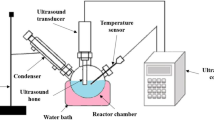

This research aims to produce a novel biodiesel fuel with standard quality from the non-edible oil with Lithium doped Calcium Oxide (Li–CaO) based heterogeneous nanocatalyst derived from Musa balbisiana Root ash. The characterization of the prepared nanocatalysts was achieved by X-ray diffractometer (XRD), Brunauer–Emmett–Teller (BET), Fourier transform infrared (FTIR), energy dispersive X-ray (EDX), scanning electron microscopy (SEM), X-Ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM) techniques. Moreover, the production time and yield were optimized by a novel Hybrid Response Surface Methodology along with African Buffalo Optimization (HRSM-ABO) algorithm. The proposed method simulation was done on the Matlab platform. According to the simulation and experimental outcomes, the optimum biodiesel yield of nearly 97.8% was achieved at the conditions that the 4 wt% of catalyst amount, 15:1 methanol to the oil of molar ratio, reaction time of 150 min and the reaction temperature of 65 °C with Amplitude of 75%. Consequently, reusability investigation proved that there the catalytic action of the improved catalyst was moderately decreased after 7 cycles. The mechanism of the proposed transesterification process was understood by the estimation of kinetic study. Furthermore, the physiochemical properties of the proposed biodiesel were measured. This result signified that the newly prepared Li–CaO was the most suitable catalyst to make biodiesel, which can be utilized in diesel engines.

Similar content being viewed by others

References

Martins F, Felgueiras C, Smitkova M, Caetano N (2019) Analysis of fossil fuel energy consumption and environmental impacts in European countries. Energies 12(6):964. https://doi.org/10.3360/en12060964

Bhuiya MMK, Rasul MG, Khan MMK, Ashwath N (2014) Second generation biodiesel: potential alternative to-edible oil-derived biodiesel. Energy Procedia 61:1969–1972. https://doi.org/10.1016/j.egypro.2014.12.054

Boonyuen S, Smith SM, Malaithong M, Prokaew A, Cherdhirunkorn B, Luengnaruemitchai A (2018) Biodiesel production by a renewable catalyst from calcined Turbo jourdani (Gastropoda: Turbinidae) shells. J Clean Prod 177:925–929. https://doi.org/10.1016/j.jclepro.2017.10.137

Demirbas A (2006) Biodiesel production via non-catalytic SCF method and biodiesel fuel characteristics. Energ Convers Manage 47(15–16):2271–2282. https://doi.org/10.1016/j.enconman.2005.11.019

Meher LC, VidyaSagar D, Naik SN (2006) Technical aspects of biodiesel production by transesterification - a review. Renew Sust Energ Rev 10:248–268. https://doi.org/10.1016/j.rser.2004.09.002

Georgogianni KG, Katsoulidis AK, Pomonis PJ (2009) Transesterification of rapeseed oil for the production of biodiesel using homogeneous and heterogeneous catalysis. Fuel Process Technol 60(7–8):1016–1022. https://doi.org/10.1016/j.fuproc.2009.03.002

Idrissou Y, Mazari T, Benadji S, Hamdi M (2016) Homogeneous and heterogeneous sunflower oil methanolysis over 12-tungstophosphoric, sulfuric and boric acids. React Kinet Mech Cat 119(1):291–304. https://doi.org/10.1007/s11144-016-1042-5

Jamal Y, Rabie A, Boulanger BO (2015) Determination of methanolysis rate constants for low and high fatty acid oils using heterogeneous surface reaction kinetic models. React Kinet Mech Cat 114(1):63–74. https://doi.org/10.1007/s11144-014-0780-5

Navas MB, Lick ID, Bolla PA, Casella ML, Ruggera JF (2018) Transesterification of soybean and castor oil with methanol and butanol using heterogeneous basic catalysts to obtain biodiesel. Chem Eng Sci 187:444–454. https://doi.org/10.1016/j.ces.2018.04.068

Puna JF, Correia MJN, Dias APS, Gomes J (2013) Biodiesel production from waste frying oils over lime catalysts. React Kinet Mech Cat 109(2):405–415. https://doi.org/10.1007/s11144-013-0557-2

Ilgen O (2011) Dolomite as a heterogeneous catalyst for transesterification of canola oil. Fuel Process Technol 92(3):452–455. https://doi.org/10.1016/j.fuproc.2010.10.009

Sirisomboonchai S, Abuduwayiti M, Guan G (2015) Biodiesel production from waste cooking oil using calcined scallop shell as catalyst. Energ Convers Manage 95:242–247. https://doi.org/10.1016/j.enconman.2015.02.044

Kumar A (2018) Global warming, climate change and greenhouse gas mitigation. Biofuels: Greenhouse Gas Mitigation and Global Warming, New Delhi: Springer, pp. 1–16

Seffati K, Honarvar B, Esmaeili H, Esfandiari N (2019) Enhanced biodiesel production from chicken fat using CaO/CuFe2O4nanocatalyst and its combination with diesel to improve fuel properties. Fuel 235:1238–1244. https://doi.org/10.1016/j.fuel.2018.08.118

Ala'aH, JamilF, Al-HajL, MyintMTZ, Mahmoud E. (2018). Biodiesel production over a catalyst prepared from biomass-derived waste date pits. Biotechnol Rep, 20: e00284

Mazaheri H, Ong HC, Masjuki HH, Amini Z (2018) Rice bran oil based biodiesel production using calcium oxide catalyst derived from Chicoreusbrunneus shell. Energy 144:10–19. https://doi.org/10.1016/j.energy.2017.11.073

Arul E, Raja K, Krishnan S, Sivaji K, Das SJ (2018) Bio-directed synthesis of calcium oxide (CaO) nanoparticles extracted from limestone using honey. J Nanosci Nanotechno 18:5760–5793. https://doi.org/10.1166/jnn.2018.15386

Hoseini SS, Najafi G, Ghobadian B, Mamat R (2018) Ailanthus altissima (tree of heaven) seed oil: characterisation and optimisation of ultrasonication-assisted biodiesel production. Fuel 220:621–630. https://doi.org/10.1016/j.fuel.2018.01.094

Liu JZ, Cui Q, Kang YF, Meng Y, Gao MZ, Efferth T (2019) Euonymus maackii rupr. seed oil as a new potential non-edible feedstock for biodiesel. Renew Energy 133:261–267. https://doi.org/10.1016/j.renene.2018.10.035

Jeon Y, Chi WS, Hwang J, Kim JH, Shul YG (2019) Core-shell nanostructured heteropoly acid-functionalized metal-organic frameworks: Bifunctional heterogeneous catalyst for efficient biodiesel production. Appl Catal B-Environ 242:51–59. https://doi.org/10.1016/j.apcatb.2018.09.071

Teo SH, Islam A, Chan ES, Choong SYT (2019) Efficient biodiesel production from Jatrophacurcus using CaSO4/Fe2O3-SiO2 core-shell magnetic nanoparticles. J Clean Prod 208:816–826. https://doi.org/10.1016/j.jclepro.2018.10.107

Deng X, Fang Z, Liu Yh, Yu CLL (2011) Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. ENERGY 36(2):777–784. https://doi.org/10.1016/j.energy.2010.12.043

Fard RGZ, Jafari D, Palizian M, Esfandyari M (2019) Biodiesel production from beef tallow using the barium oxide catalyst. React Kinet Mech Cat 128(2):723–738. https://doi.org/10.1007/s11144-019-01672-z

Kesserwan F, Ahmad MN, Khalil M (2020) Hybrid CaO/Al2O3 aerogel as heterogeneous catalyst for biodiesel production. Chem Eng J 385:123834. https://doi.org/10.1016/j.cej.2019.123834

Wong WY, Lim S, Pang YL, Shuit SH, Chen WH (2020) Synthesis of renewable heterogeneous acid catalyst from oil palm empty fruit bunch for glycerol-free biodiesel production. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2020.138534

Hossain SMZ, Taher S, Khan A, Sultana N, Irfan MF Experimental study and modeling approach of response surface methodology coupled with crow search algorithm for optimizing the extraction conditions of papaya seed waste oil. Arab J Sci Eng, 1–13

Kalanakoppal Venkatesh Y, Mahadevaiah R, Haraluru Shankaraiah L, Ramappa S, Sannagoudar Basanagouda A (2018) Preparation of a CaO nanocatalyst and its application for biodiesel production using butea monosperma oil: an optimization study. JAOCS, J Am Oil Chem Soc 95:635–649. https://doi.org/10.1002/aocs.12079

Ismail S, Ahmed AS, Anr R, Hamdan S (2016) Biodiesel production from castor oil by using calcium oxide derived from mud clam shell. J Renew Energ 2013:1–8. https://doi.org/10.1155/2016/5274917

Konwar LJ, Boro J, Deka D (2018) Activated carbon supported cao from waste shells as a catalyst for biodiesel production. Energy Sources, Part A: Recovery, Util Environ Effects 40:601–607. https://doi.org/10.1080/15567036.2012.733483

Vardast N, Haghighi M, Dehghani S (2019) Sono-dispersion of calcium over Al-MCM-41used as a nanocatalyst for biodiesel production from sunflower oil: influence of ultrasound irradiation and calcium content on catalytic properties and performance. Renew Energ 132:979–988. https://doi.org/10.1016/j.renene.2018.08.046

Wayne LL, Gachotte DJ, Walsh TA (2019) Transgenic and genome editing approaches for modifying plant oils. Transgenic Plants, New York: Humana Press, pp. 367–394

Mohadesi M, Moradi G, Ghanbari M, Moradi MJ (2019) Investigating the effect of n-hexane as solvent on waste cooking oil conversion to biodiesel using CaO on a new support as catalyst. Meas: J Int Meas Confed 135:606–612

Boey PL, Maniam GP, Hamid SA (2011) Performance of calcium oxide as a heterogeneous catalyst in biodiesel production: a review. Chem Eng J 168(1):15–22. https://doi.org/10.1016/j.cej.2011.01.009

Kelarijani AF, Zanjani NG, Pirzaman AK (2019) Ultrasonic assisted transesterification of rapeseed oil to biodiesel using nano magnetic catalysts. Waste Biomass Valori. https://doi.org/10.1007/s12649-019-00593-1

Sanford SD, White JM, Shah PS, Wee C (2009) Feedstock and biodiesel characteristics report. Renew Energy Group 413:1–136

Kumar D, Ali A (2010) Nanocrystalline lithium ion impregnated calcium oxide as heterogeneous catalyst for transesterification of high moisture containing cotton seed oil. Energy Fuels 24:2091–2097. https://doi.org/10.1021/ef601318s

Narula V, Khan MF, Negi A, Kalra S, Thakur A, Jain S (2017) Low temperature optimization of biodiesel production from algal oil using CaO and CaO/Al2O3 as catalyst by the application of response surface methodology. Energy 140:879–884. https://doi.org/10.1016/j.energy.2017.09.028

Odili JB, Kahar MNM, Anwar S (2015) African buffalo optimization: a swarm-intelligence technique. Procedia Comput Sci 76:443–448. https://doi.org/10.1016/j.procs.2015.12.291

Galvan D, Cremasco H, Mantovani ACG, Bona E (2020) Kinetic study of the transesterification reaction by artificial neural networks and parametric particle swarm optimization. Fuel 267:117221. https://doi.org/10.1016/j.fuel.2020.117221

Ming C, Rizwanul Fattah IM, Chan QN, Pham PX, Medwell PR, Kook S, Yeoh GH, Hawkes ER, Masri AR (2018) Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 224:167–177. https://doi.org/10.1016/j.fuel.2018.03.053

Sarma AK, Kumar P, Aslam M, Chouhan APS (2014) Preparation and characterization of Musa balbisiana colla underground stem nano-material for biodiesel production under elevated conditions. Catal Lett 144(7):1344–1353. https://doi.org/10.1007/s10562-014-1206-8

Da Silva CL, Barañano AG, Pinheiro CJG, Menini L, Pinheiro PF (2019) Biodiesel production from cotton oil using heterogeneous CaO catalysts from eggshells prepared at different calcination temperatures. Green Process Synth 8:235–244. https://doi.org/10.1515/gps-2018-0076

Rezaei R, Mohadesi M, Moradi GR (2013) Optimization of biodiesel production using waste mussel shell catalyst. Fuel 109:534–541. https://doi.org/10.1016/j.fuel.2013.03.004

Acknowledgement

None

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors proclaim that they have no potential conflict of interest.

Ethical approval

All applicable institutional and/or national guidelines for the care and use of animals were followed.

Informed consent

For this type of investigation formal consent is not required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, U., Gupta, P. Modeling and optimization of novel biodiesel production from non-edible oil with musa balbisiana root using hybrid response surface methodology along with african buffalo optimization. Reac Kinet Mech Cat 130, 875–901 (2020). https://doi.org/10.1007/s11144-020-01807-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01807-7