Abstract

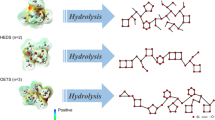

The influence of reaction conditions (amount and type of the catalyst, the reaction temperature, the type of the solvent) on the reaction course of the acetalization of aldehydes with diols was tested in this paper. The optimization of reaction conditions was performed on model reaction, acetalization of 2-methylpentanal by 2-methyl-2-propyl-1,3-propanediol leading to the formation of fragrant compound 2-(1-methylbutyl)-5-methyl-5-propyl-1,3-dioxane (Troenan). p-Toluenesulfonic acid was used as an active homogeneous catalyst. It appeared to be advantageous not to use any solvent in the reaction. Using 0.3 wt% of the catalyst the almost total conversion of 2-methylpentanal was achieved after 240 min of reaction at room temperature while the selectivity to the desired product was about 98%. The optimized reaction conditions were applied to the preparation of four cyclic fragrant acetals (namely 2-hexyl-1,3-dioxolane, 2-hexyl-4-methyl-1,3-dioxolane, 2-benzyl-5-hydroxy-1,3-dioxane and 2-(1-methylbutyl)-5-methyl-5-propyl-1,3-dioxane) in larger scale; and these were sensory evaluated after purification step. Prepared heterogeneous catalysts, acid modified montmorillonite (MMT) K-10 (treated by H2SO4, HNO3, and HCl) were successful in the model reaction. The conversion of 2-methylpentanal over 90% was achieved using acid modified MMT after 300 min of reaction at room temperature, the selectivity to the desired product was about 98%. MMT/H2SO4 can be used in the model reaction four times without any change in the reaction course, what makes it promising for the further application.

Similar content being viewed by others

References

Sekerová L, Frýbová M, Vyskočilová E, Červený L (2017) Proceeding paper, ICCT Mikulov, poster, http://www.icct.cz/AngiologyKlon-ICCT/media/system/ICCT2017-full_papers.pdf. Accessed 13 Nov 2018

Climent MJ, Corma A, Velty A (2004) Appl Catal A 263:155–161

Ledneczki I, Darányi M, Fulop F, Molnár Á (2005) Catal Today 100:437–440

Wang B, Gu Y, Song G, Yang T, Yang L, Suo J (2005) J Mol Catal A 233(1):121–126

Silva VMTM, Gandi GK, Ridrigues AE (2007) Development of simulated moving bed reactor using a cation exchange resin as a catalyst and adsorbent for the synthesis of acetals in ion exchange and solvent extraction, a series of advance. In: SenGupta AK (ed), CRC Press Taylor and Francis, Boca Raton, p 45

Surburg H, Panten J (2006) Common fragrance and flavour materials. Wiley, Weinheim

Cherkaev G, Timonin SA, Yakovleva GF, Shutikova L, Mikhailova AS, Shapiro LD (1987) Patent: US 1 337 384

Upadek H, Bruns K (1980) Patent: DE 3016007 A1

Markert T, Merkel D, Altenbach HJ (1999) Patent: WO 99/02515

Rossiter KJ (1999) Patent: US 005888961 A

Lappe P, Schmid K, Söllner R, Springer H (2002) Patent: EP 1 316 553 A1

Yadav GD, Katole SO (2014) Catal Today 237:125–135

Kowalska-Kus J, Held A, Nowinska K (2016) Reac Kinet Mech Cat 117(1):341–352

Rodrigues R, Mandelli D, Goncalves NS, Pescarmona PP, Carvalho WA (2016) J Mol Catal A 422:122–130

Wang W, Wang Y, Cheng W, Wang J, Yang J, He M (2008) Chin Sci Bull 53(17):2612–2616

Silva CAC, Figueiredo FCA, Rodrigues R, Sairre MI, Gonsalves M, Matos I, Fonseca IM, Mandelli D, Carvalho WA (2016) Clean Technol Environ 18(5):1551–1563

Farook A, Batagarawa MS, Hello KM, Al-Juaid SS (2012) Chem Pap 66(11):1048–1058

Gutiérrez-Acebo E, Guerrero-Ruiz F, Centenero M, Martínez JS, Salagre P, Cesteros Y (2018) Open Chem 16(1):386–392

Li R, Song H, Chen J (2018) Catalysts 8(8):297–314

Nandan E, Sreenivasulu P, Konathala LNS, Kumar M, Viswanadham N (2013) Microporous Mesoporous Mater 179:182–190

Arctander S, Perfume and Flavor Chemicals (1969) Aroma chemicals. Montclair, Montclair

Perflavory Information system; www.perflavory.com. Accessed 20 Dec 2018

Weber L, Al-Refae K, Ebbert J, Jägers P, Altmüller J, Becker Ch, Hahn S, Gisselmann G, Hatt H (2017) PLoS ONE 12(3):1–27

Kotachi S, Fukuda K (2010) Patent: EP 1 939 193 B1

Baishya G, Sarman B, Hazarika N (2013) Synlett 24(9):1137–1141

Vyskočilová E, Gruberová A, Shamzhy M, Vrbková E, Krupka J, Červený L (2018) Reac Kinet Mech Cat 124:711–725

Bieseki L, Bertellab F, Treichelc H, Penhad FG, Perghera SBC (2013) Mater Res 16(5):1122–1127

Pushpletha P, Rugmini S, Lalithambika M (2005) Appl Clay Sci 30:141–153

Virtual Textbook of Organic Chemistry, Michigan State University, Dep. Of Chemistry, www2.chemistry.msu.edu/faculty/reusch/VirtTxtjml/enrgtop.htm#top4. Accessed 20 Dec 2018

Kurbanov D, Pastushenko EV, Kheikimov YK, Zlotskii SS, Rakhmankulov DL (1984) Izvestiya Akademii Nauk Turkmenskoi SSR. Seriya Fiziko-Tekhnicheskikh, Khimicheskikh i Geologicheskikh Nauk 1:108–109

Product Data Sheet, Dow Chemical; http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_09b7/0901b803809b7b11.pdf?filepath=liquidseps/pdfs/noreg/177-03087.pdf&fromPage=GetDoc. Accessed 20 Dec 2018

Niva M, Suzuki K, Katada N (2006) Proceeding paper; presented at 16th Saudi Arabia-Japan Joint Symposium, Dahran, Saudi Arabia

Acknowledgements

This work was realized within the Operational Programme Prague – Competitiveness (CZ.2.16/3.1.00/24501) and “National Program of Sustainability” ((NPU I LO1613) MSMT-43760/2015). We also acknowledge Specific University Research (MSMT NO 21-SVV/2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sekerová, L., Spáčilová, M., Vyskočilová, E. et al. Acid catalyzed acetalization of aldehydes with diols resulting into the formation of fragrant cyclic acetals. Reac Kinet Mech Cat 127, 727–740 (2019). https://doi.org/10.1007/s11144-019-01595-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-019-01595-9