Abstract

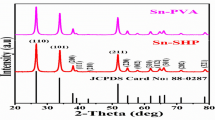

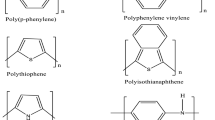

In this work, we described the synthesis of a nanocatalyst, which consists of polyaniline (PANI)/multiwall carbon nanotubes (MWCNTs) and the deposited Pd nanoparticles. FT-IR, X-ray diffraction, X-ray photoelectron spectroscopy, thermogravimetric analysis (TG) and transmission electron microscopy were used to characterize the nanocatalyst. The interaction between PANI and MWCNTs have been explained according to the results of the FT-IR and XRD analysis. This complex was an efficient catalyst for the Heck reactions of acrylic acid with aryl iodides in air at low temperature (60 °C) using 0.9 mol% Pd of the catalyst. Furthermore, it also exhibited catalytic properties for the bromide and activated chlorobenzene. The yield of cinnamic acid was 71 % for the Heck reaction of acrylic acid with iodobenzene even though the complex was used nine times.

Similar content being viewed by others

References

Iijima S (1991) Nature 354:56

Dai HJ, Hafner JH, Rinzler AG, Colbert DT, Smalley RE (1996) Nature 384:147

Baughman RH, Zakhidov AA, de Heer WA (2002) Science 297:787

Odon TW, Huang J, Kim P, Lieber CM (1998) Nature 391:62

Kong J, Franklin NR, Zhou C, Chaplines MG, Peng S, Cho K (2000) Science 287:622

Miyako E, Nagata H, Hirano K, Makita Y, Hirotsu T (2007) Nanotechnology 18:475103

Dieckmann G, Dalton A, Johnson P, Razal J, Chen J, Giordano G, Munoz E, Musselman I, Baughman R, Draper R (2003) J Am Chem Soc 125:1770

Song S, Yang H, Rao R, Liu H, Zhang A (2010) Appl Catal A 375:265

Neelgund GM, Oki A (2011) Appl Catal A 399:154

Qiu B, Lin Z, Wang J, Chen Z, Chen J, Chen G (2009) Talanta 78:76

Sheng Q, Zheng J (2009) Bioelectron 24:1621

Ragupathy D, Gopalan AI, Lee KP (2009) Electrochem Commun 11:397

Beletskaya IP, Cheprakov AV (2000) Chem Rev 100:3009

Polshettiwar V, Molnar A (2007) Tetrahedron 63:6949

C. Amatore, A. Jutand, Acc (2000) Chem Res 33: 314

Clark JH, Macquarries DJ (2000) Green Chem 2:53

Yamada MA, Takeda K, Takahashi H (2004) Tetrahedron 60:4097

Kalbasi RJ, Mosaddegh N (2012) Mater Res Bull 47:160

Islam RU, Witcomb MJ, Mallick K (2010) Catal Commun 12:116

Mondal J, Modak A, Bhaumik A (2011) J Mol Catal A Chem 350:40

Zhu J, Zhou JH, Zhao TJ (2009) Appl Catal A Gen 352:243

Xu Y, Xue M, Li JJ, Zhang LJ, Cui YC (2010) Reac Kinet Mech Cat 100:347

Gao C, Vo CD, Jin YZ, Li WW (2005) Macromolecules 38:8634

Mi HY, Zhang XG (2007) Electrochem Commun 9:2859

Neelgund GM, Oki A (2011) J Nanosci Nanotechnol 11:3621

Sun DP, Yang JZ, Li J, Xu X, Yang X (2010) Appl Surf Sci 256:2241

Selvakumar K, Zapf A, Beller M (2002) Org Lett 4:3031

Prockl S, Kleist W, Gruber MA, Kohler K (2004) Angew Chem Int Ed 43:1917

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, G., Zhang, L. & Cui, Y. Preparation of Pd nanoparticles deposited on a polyaniline/multiwall carbon nanotubes nanocomposite and their application in the Heck reaction. Reac Kinet Mech Cat 108, 193–204 (2013). https://doi.org/10.1007/s11144-012-0506-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-012-0506-5