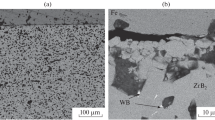

The interaction in the ZrB2–Ni system with change in the ZrB2 content from 3.5 to 75 wt.% has been studied. It is shown that the process occurs through the contact melting mechanism, leading to the formation of a liquid phase, wetting the substrate with a contact angle of about 50°, even at 1250°C. The liquid phase interacts with the substrate and crystallizes with time as more refractory compounds are formed. The structure and phase composition of the reaction products are determined by the ratio of alloy components, representing double, triple, and more complex compounds based on the crystalline lattices of Zr–Ni intermetallides. The eutectic point is found at 13% ZrB2 in the alloy. The eutectic nature of the ZrB2–Ni quasibinary phase diagram restricts the upper temperature limit for application of the alloys and associated materials in friction joints of fuel equipment. Considering that they may undergo solid-phase interaction, the upper temperature limit is 1000°C.

Similar content being viewed by others

References

S.R. Levine, E.J. Opila, M.C. Yolbig, J.D. Riser, M. Singh, and J.A. Solem, “Evaluation of ultrahigh temperature ceramics for aeropropulsion use,” J. Eur. Ceram. Soc., 22, 2757–2767 (2002).

Resaie Alireza, V.G. Fahrenholtz, and G.E. Hilmans, “Evolution of structure during the oxidation of zirconium diboride in air up to 1500°C,” J. Eur. Ceram. Soc., 27, 2495–2501 (2007).

G.V. Samsonov, A.D. Panasyuk, and M.S. Borovikova, “Contact reaction between refractory compounds and liquid metals. IV. Reaction between refractory borides and liquid iron group metals,” Powder Metall. Met. Ceram., 12, No. 6, 476–480 (1973).

V.I. Tumanov, A.E. Gorbunov, and V.M. Kondratenko, “Wettability and properties of mono- and diborides of IVa and VIa group metals,” in: Wettability and Surface Properties of Melts and Solids [in Russian], Naukova Dumka, Kyiv (1972), pp. 102–105.

G.V. Samsonov, A.D. Panasyuk, and M.S. Borovikova, “Wettability of 1Va subgroup metal borides with nickel metals,” in: Melt Adhesion [in Russian], Naukova Dumka, Kyiv (1974), pp. 142–144.

I.M. Fedorchenko and R.A. Andrievskii, Fundamentals of Powder Metallurgy [in Russian], Izd. Akad. Nauk USSR, Kyiv (1961), p. 420.

V.M. Zalkin, Nature of Eutectic Alloys and Effect of Contact Melting [in Russian], Metallurgiya, Moscow (1987), p. 152.

Yu.V. Voroshilov and Yu.B. Kuzma, “Reaction of zirconium with the transition metals and boron,” Powder Metall. Met. Ceram., 8, No. 11, 941–944 (1969).

C. Artini, M.L. Muolo, and A. Passerone, “Experimental investigations and thermodynamic modeling in the ZrB2ANi section of the BANiAZr system,” J. Alloys Compd., 592, 115–120 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 9–10 (523), pp. 69–75, 2018.

Rights and permissions

About this article

Cite this article

Zhunkovskii, G., Mosina, T., Neshpor, I. et al. Contact Interaction of Zirconium Diboride with Nickel and its Alloys. I. The Features of Contact Interaction in the ZrB2–Ni System. Powder Metall Met Ceram 57, 551–556 (2019). https://doi.org/10.1007/s11106-019-00014-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-019-00014-x