To design a wear-resistant material operated at high temperatures, the physical and mechanical properties of the new nickel alloy (whose components are heat-resistant alloy ZhS32-VI and 30–50% titanium carbide) obtained by powder metallurgy are investigated. It is shown that the temperature where the alloy starts melting is 1360 ± 10°C, the wear resistance at <1050°C doubles that of nickel-based powder alloys with titanium carbide, while the heat resistance at 1100°C satisfies the requirements of the intended alloys. It is shown that the obtained alloy can be plasma-sprayed onto the blade material and used for protecting the contacting surfaces of GTE blades against wear.

Similar content being viewed by others

References

G. P. Dmitrieva and T. S. Cherepova, “Wear resistance of cobalt–carbide eutectic alloy in gas-dynamic loading,” Metal. Nov. Tekhnol., 35, No. 10, 1383–1390 (2013).

G. P. Dmitrieva, T. S. Cherepova, T. A. Kosorukova, and V. I. Nychyporenko, “Structure and properties of cobalt-based wear-resistant alloy with niobium carbide,” Metal. Nov. Tekhnol., 37, No. 7, 973–986 (2015).

T. S. Cherepova, G. P. Dmitrieva, A. V. Nosenko, and O. M. Semirga, “Wear-resistant alloy for protecting contact surfaces of aircraft engine working blades against oxidizing at high temperatures,” Nauka Innov., 10, No. 4, 22–31 (2014).

V. A. Leontiev, S. D. Zalichikhis, E. V. Kondratyuk, and V. E. Zamkovoi, “Restoring GTE to working conditions using new techniques and materials,” Vest. Dvigatelestr., No. 4, 99–103 (2006).

G. I. Peichev, A. K. Shurin, L. I. Ivshchenko, et al., “Wear-resistant alloys for contact surfaces of GTE parts,” Vest. Dvigatelestr., No. 2, 188–192 (2006).

A. K. Shurin, “Studying phase equilibriums and structure of alloys with introduction phases for developing materials with composite reinforcement,” in: Phase Equilibriums in Metal Alloys [in Russian], Nauka, Moscow (1981), pp. 209–217.

G. Dmitrieva and T. Cherepova, “Melting diagram of Cobalt-rich alloys in the system C–Co–Nb,” Chem. Met. Alloys, No. 8, 83–90 (2015).

T. S. Cherepova and G. P. Dmitrieva, “The wear features of powder cobalt alloys strengthened with titanium carbide,” Powder Metall. Met. Ceram., 55, Nos. 5–6, 374–378 (2016).

T. S. Cherepova, G. P. Dmitrieva, O. I. Dukhota, and M. V. Kindrachuk, “Features of powder nickel alloys strengthened with titanium carbide,” Fiz. Khim. Mekh. Mater., 52, No. 2, 29–34 (2016).

T. S. Cherepova, G. P. Dmitrieva, O. I. Dukhota, and M. V. Kindrachuk, Wear-Resistant Nickel Alloy, Patent 111036 Ukraine, MPK C22C 19/05, C22C 29/02, Publ. Mar 10, 2016.

V. N. Salivon and A. A. Kozakov, Age-Hardened Nickel-Based Alloy, Patent 2016119 Russian Federation, MPK C22C 19/05, Publ. Jul 15, 1994.

E. N. Kablov, Heat-resistant structural materials,” Liteinoye Proiz., No. 7, 2–7 (2005).

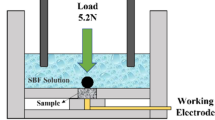

O. I. Dukhota and O. V. Tisov, “Studying wear resistance of heat-resistant composite alloys in hightemperature fretting,” Prob. Ter. Znosh., No. 53, 195–200 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 56, Nos. 11–12 (518), pp. 68–75, 2017.

Rights and permissions

About this article

Cite this article

Dmitrieva, G.P., Cherepova, T.S., Dukhota, A.I. et al. Properties of ZhS32-VI Powder Alloys with Titanium Carbide. Powder Metall Met Ceram 56, 664–669 (2018). https://doi.org/10.1007/s11106-018-9941-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9941-9