Nitinol (NiTi) exists in an equiatomic phase of Ni and Ti. Nitinol has growing applications in aerospace and medical industries due to its unique properties of pseudoelasticity, corrosion resistance, shape memory effect, and biocompatibility. NiTi can be produced by conventional and nonconventional manufacturing routes and its behavior can be modified by altering the composition, changing the porosity, and shape setting under varying thermal and mechanical treatment. After the fabrication, several post-processing operations are required on NiTi for desired application. This paper presents a brief on post-processing like machining, surface coating, and mechanical and thermal treatment for shape setting of NiTi alloys, and their issues and challenges.

Similar content being viewed by others

References

F. D. Whitcher, “Simulation of in vivo loading conditions of nitinol vascular stent structures,” Comput. Struct., 64, 1005–1011 (1997).

M. Catauro, M. G. Raucci, M. A. Continenza, and A. Marotta, “Biocompatibility tests with fibroblasts of CaO rich calcium silicate glasses,” J. Mater. Sci., 39, 373–375 (2004).

N. Sharma, T. Raj, and K. Kumar, “Applications of nickel titanium alloy,” J. Eng. Technol., 5, 1–7 (2015).

L. S. Castleman, S. M. Motzkin, F. P. Alicandri, and V. L. Bonawit, “Biocompatibility of nitinol alloy as an implant material,” J. Biomed. Mater. Res., 10, 695–731 (1976).

M. Es-Souni, M. Es-Souni, and H. F. Brandies, “Assessing the biocompatibility of NiTi shape memory alloys used for medical applications,” Anal. Bioanal. Chem., 381, 557–567 (2005).

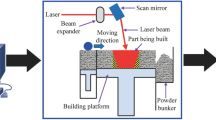

B. V. Krishna, S. Bose, and A. Bandyopadhyay, “Laser processing of net-shape NiTi shape memory alloy,” Metall. Mater. Trans. A, 38, 1096–1103 (2007).

J. Y. Xiong, Y. C. Li, X. J. Wang, et al., “Titanium–nickel shape memory alloy foams for bone tissue engineering,” J. Mech. Behav. Biomed. Mater., 1, 269–273 (2008).

N. Sharma, K. Kumar, and T. Raj, “Fabrication of NiTi alloys: a review,” Proc. Inst. Eng., Part L: J. Mater. Des. Appl.; doi: https://doi.org/10.1177/1464420715622494 (2015).

H. C. Lin, K. M. Lin, and I. S. Cheng, “The electro-discharge machining characteristics of NiTi shape memory alloys,” J. Mater. Sci., 36, 399–404 (2001).

H. C. Lin, K. M. Lin, and Y. C. Chen, “A study on the machining characteristics of TiNi shape memory alloys,” J. Mater. Proc. Technol., 105, 327–332 (2000).

K. Weinert and V. Petzoldt, “Machining of NiTi based shape memory alloys,” Mater. Sci. Eng. A., 378, 180–184 (2004).

M. Manjaiah, S. Narendranath, S. Basavarajappa, and V. N. Gaitonde, “Wire electric discharge machining characteristics of titanium nickel shape memory alloy,” Trans. Nonferrous Met. Soc. China, 24, 3201–3209 (2014).

R. Piquard, A. Dacunto, P. Laheurte, and D. Dudzinski, “Micro-end milling of NiTi biomedical alloys, burr formation and phase transformation,” Precis. Eng., 38, 356–364 (2014).

Y. Kaynak, H. E. Karaca, R. D. Noebe, and I. S. Jawahir, “Tool-wear analysis in cryogenic machining of NiTi shape memory alloys: a comparison of tool-wear performance with dry and MQL machining,” Wear, 306, 51–63 (2013).

H. C. Lin, K. M. Lin, and Y. C. Chen, “A study on the machining characteristics of TiNi shape memory alloys,” J. Mater. Process. Technol., 105, 327–332 (2000).

E. S. Lee, T. H. Shin, B. Y. Kim, and S. Y. Baek, “Investigation of short pulse electrochemical machining for groove process on Ni-Ti shape memory alloy,” Int. J. Prec. Eng. Manufac., 11, 113–118 (2010).

L. Xu, Y. Pan, and C. Zhao, “Distance effects in electrochemical micromachining,” Scientific Reports, 6 (2016), Article number 31778; doi: https://doi.org/10.1038/srep31778.

X. Ma, L. Zhang, G. Cao, et al., “Electrochemical micromachining of nitinol by confined-etchant-layer technique,” Electrochim. Acta,. 52, 4191–4196 (2007).

M. C. Kong, D. Axinte, and W. Voice, “Challenges in using waterjet machining of NiTi shape memory alloys: an analysis of controlled-depth milling,” J. Mater. Process. Technol., 211, 959–971 (2011).

M. Frotscher, F. Kahleyss, T. Simon, et al., “Achieving small structures in thin NiTi sheets for medical applications with water jet and micro machining: a comparison,” J. Mater. Eng. Perform., 15, 776–782 (2011).

A. T. Tung, G. Niemeyer, B. Park, and D. H. Liang, “Laser-machined shape memory alloy actuators for active catheters,” ASME Trans. Mechatron., 12, 439–446 (2007).

A. T. Tung, B. Park, and D. H. Liang, “Laser-machined shape memory alloy sensors for position feedback in active catheters,” Sens. Actuators A, 147, 83–92 (2008).

R. Pfeifer, D. Herzog, M. Hustedt, and S. Barcikowski, “Nd:YAG laser cutting of NiTi shape memory alloys—influence of process parameters,” J. Mater. Proc. Technol., 210, 1918–1925 (2010).

C. Li, S. Nikumb, and F. Wong, “An optimal process of femtosecond laser cutting of NiTi shape memory alloy for fabrication of miniature devices,” Opt. Lasers Eng., 44, 1078–1087 (2006).

N. Sharma, T. Raj, and K. K. Kumar, “Parameter optimization and experimental study on wire electrical discharge machining of porous Ni40Ti60 alloy,” Proc. Inst. Eng. Part B J. Eng. Manuf., doi: https://doi.org/10.1177/0954405415577710 (2015).

S. F. Hsieh, S. L. Chen, H. C. Lin, et al., “The machining characteristics and shape recovery ability of Ti–Ni–X (X = Zr, Cr) ternary shape memory alloys using the wire electro-discharge machining,” Int. J. Mach. Tools Manuf., 49, 509–514 (2009).

M. P. Jahan, M. Rahman, and Y. S. Wong, “A review on the conventional and micro-electric discharge machining of tungsten carbide,” Int. J. Mach. Tools Manuf., 51, 837–859 (2011).

W. Theisen and A. Schuermann, “Electro-discharge machining of nickel–titanium shape memory alloys,” Mater. Sci. Eng. A, 378, 200–204 (2004).

H. Lin, K. Lin, Y. Chen, and C. Chu, “The wire electro-discharge machining characteristics of Fe–30Mn–6Si and Fe–30Mn–6Si–5Cr shape memory alloys,” J. Mater. Process. Technol., 161, 435–439 (2005).

M. Manjaiah, S. Narendranath, and S. Basavarajappa, “Review on nonconventional machining of shape memory alloy,” Trans. Nonferrous Met. Soc. China, 24, 12–21 (2014).

F. Klocke, D. Welling, and J. Dieckmanna, “Comparison of grinding and wire EDM concerning fatigue strength and surface integrity of machined Ti–6Al–4V components,” Procedia Eng., 19, 184–189 (2011).

O. Yilmaz and M. A. Okka, “Effect of single and multi-channel electrodes application on EDM fast hole drilling performance,” Int. J. Adv. Manuf. Technol., 51, 185–194 (2010).

E. S. Lee and T. H. Shin, “An evaluation of the machinability of nitinol shape memory alloy by electrochemical polishing,” J. Mech. Sci. Technol., 25, 963–969 (2011).

S. L. Chen, S. F. Hsieh, H. C. Lin, et al., “Electrical discharge machining of TiNiCr and TiNiZr ternary shape memory alloys,” Mater. Sci. Eng. A, 445–446, 486–492 (2007).

H. R. Sabouni and S. Daneshmand, “Investigation of the parameters of EDM process performed on smart NiTi alloy using graphite tools,” Life Sci. J., 9, 504–510 (2012).

K. K. Jangra, “An experimental of multi-pass cutting operation in wire electrical discharge machining of WC–5.3% Co composite,” Int. J. Adv. Manuf. Technol., 76, 971–982 (2015).

T. Zhao, Y. Li, Y. Liu, and X. Zhao, “Nanohardness, wear resistance and pseudoelasticity of hafnium implanted NiTi shape memory alloy,” J. Mech. Behav. Biomed. Mater., 13, 174–184 (2012).

R. W. Y. Poon, J. P. Y. Ho, X. Liu, et al., “Improvements of anticorrosion and mechanical properties of NiTi orthopedic materials by acetylene, nitrogen and oxygen plasma immersion ion implantation,” Nucl. Instrum. Methods Phys. Res. B, 237, 411–416 (2005).

R. W. Y. Poon, J. P. Y. Ho, X. Liu, et al., “Formation of titanium nitride barrier layer in nickel–titanium shape memory alloys by nitrogen plasma immersion ion implantation for better corrosion resistance,” Thin Sol. Films, 488, 20–25 (2005).

L. Tan and W. C. Crone, “Surface characterization of NiTi modified by plasma source ion implantation,” Acta Mater., 50, 4449–4460 (2002).

I. Mashal, L. Klinger, I. Gotman, and E. Y. Gutmanas, “Titanium nitride coating on nickel produced by a powder immersion reaction-assisted coating method,” Surf. Coat. Technol., 200, 3561–3566 (2006).

S. Shabalovskaya, J. Anderegg, and J. V. Humbeeck, “Critical overview of nitinol surfaces and their modifications for medical applications,” Acta Biomater., 4, 447–467 (2008).

D. Starosvetsky and I. Gotman, “Corrosion behavior of titanium nitride coated Ni–Ti shape memory surgical alloy,” Biomaterials, 22, 1853–1859 (2001).

S. Jin, Y. Zhang, Q. Wang, et al., “Influence of TiN coating on the biocompatibility of medical NiTi alloy,” Colloids Surf. B Biointerfaces, 101, 343–349 (2013).

Y. Yan, W. Yang, Y. Hu, et al., “Surface modification of NiTi alloy via a TiN coating functionalized with biomimic multilayer films,” Mater. Lett., 120, 155–158 (2014).

J. Choi, D. Bogdanski, M. Köller, et al., “Calcium phosphate coating of nickel–titanium shape memory alloys, coating procedure and adherence of leukocytes and platelets,” Biomaterials, 24, 3689–3696 (2003).

B. Bertheville, “Porous single-phase NiTi processed under Ca reducing vapor for use as a bone graft substitute,” Biomaterials, 27, 1246–1250 (2006).

K. Endo, “Chemical modification of metallic implant surfaces with bio-functional proteins. I. Molecular structure and biological activity of a modified NiTi alloy surface,” Dent. Mater. J., 14, 185–198 (1995).

B. O’Brien, W. M. Carroll, M. J. Kelly, “Passivation of nitinol wire for vascular implants—a demonstration of the benefits,” Biomaterials, 23, 1739–1748 (2002).

Y. Oshida, R. Sachdeva, and S. Miyazaki, “Microanalytical characterization and surface modification of NiTi orthodontic arch wires,” J. Biomed. Mater. Eng., 2, 51–69 (1991).

Y. Cheng, W. Cai, H. T. Li, and Y. F. Zheng, “Surface modification of NiTi alloy with tantalum to improve its biocompatibility and radiopacity,” J. Mater. Sci., 41, 4961–4964 (2006).

R. Boccaccini, C. Peters, J. A. Roether, et al., “Electrophoretic deposition of polyetheretherketone (PEEK) and PEEK/Bioglass® coatings on NiTi shape memory alloy wires,” J. Mater. Sci., 41, 8152–8159 (2006).

Z. Bai, M. J. Filiaggi, and J. R. Dahn, “Fibrinogen adsorption onto 316L stainless steel, nitinol and titanium,” Surface Sci., 603, 839–846 (2009).

D. Krause, B. Thomas, C. Leinenbach, et al., “The electrophoretic deposition of bioglass particles on stainless steel and nitinol substrates,” Surf. Coat. Technol., 200, 4835–4845 (2006).

C. Y. Zheng, F. L. Nie, Y. F. Zheng, et al., “Enhanced corrosion resistance and cellular behavior of ultrafine-grained biomedical NiTi alloy with a novel SrO–SiO2–TiO2 sol–gel coating,” Appl. Surf. Sci., 257, 5913–5918 (2011).

R. Bakhshi, A. Darbyshire, J. E. Evans, et al., “Polymeric coating of surface modified nitinol stent with POSS-nanocomposite polymer,” Colloids Surf. B: Biointerfaces, 86, 93–105 (2011).

S. K. Wu, H. C. Lin, and Y. C. Yen, “A study on the wire drawing of TiNi shape memory alloys,” Mater. Sci. Eng. A, 215, 113–119 (1996).

A. Christensen, A. Lippincott, and R. Kircher, Qualification of Electron Beam Melted (EBM) Ti6Al4VELI for Orthopaedic Implant Applications, Medical Modelling LLC, Golden, CO (2007).

T. Majid, Finite Element Analysis of Shape Memory Alloy Biomedical Devices, PhD Thesis, University of Toledo (2010), p. 234.

J. Ryhanen, Biocompatibility Evaluation of Nickel–Titanium Shape Memory Metal Alloy, PhD Thesis, University of Oulu (1999), p. 118.

C. L. Chu, J. C. Chung, and P. K. Chu, “Effects of heat treatment on characteristics of porous Ni-rich NiTi SMA prepared by SHS technique,” Transact. Nonferrous Met. Soc. China, 16, No. 1, 49–53 (2006).

X. Liu, Y. Wang, D. Yang, and M. Qi, “The effect of ageing treatment on shape-setting and superelasticity of a NiTi stent,” Mater. Charact., 59, 402–406 (2008).

K. W. K. Yeung, K. M. C. Cheung, W. W. Lu, and C. Y. Chung, “Optimization of thermal treatment parameters to alter austenitic phase transition temperature of NiTi alloy for medical implant,” Mater. Sci. Eng. A, 383, 213–218 (2004).

M. Kubenová, J. Zálesák, J. Cermák, and A. Dlouhy, “Impact of hydrogen-assisted heat treatments on microstructure and transformation path in a Ni-rich NiTi shape memory alloy,” J. All. Compd., 577S, S287–S290 (2013).

D. J. S. Ruth, K. Dhanalakshmi, and S. S. Nakshatharan, “Bidirectional angular control of an integrated sensor/actuator shape memory alloy based system,” Measurement, 69, 210–221 (2015).

S. C. Weighardt, H. J. Maier, and Y. I. Chumlyakov, “Dependence of functional degradation on crystallographic orientation in NiTi shape memory alloys aged under stress,” J. All. Compd., 577S, S219–S221 (2013).

S. Pittaccio and L. Garavaglia, “Electric resistance monitoring as a method for controlling shape memory alloy characteristics during shape settings in the furnace,” Mater. Sci. Eng. A, 599, 92–104 (2014).

M. S. Shakeri and H. Aghajani, “Modeling of stress relaxation process, case study: Shape setting heat treatment of a Ni rich–NiTi alloy,” J. All. Compd., 574, 119–123 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 56, Nos. 9–10 (517), pp. 144–157, 2017.

Rights and permissions

About this article

Cite this article

Sharma, N., Kumar, K. & Kumar, V. Post-Processing of NiTi Alloys: Issues and Challenges. Powder Metall Met Ceram 56, 599–609 (2018). https://doi.org/10.1007/s11106-018-9933-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9933-9