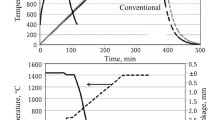

The consolidation of nanocomposite powders of refractory nitrides (TiN, Si3N4, AlN) in the microwave field (2.45 GHz) is studied. The structurization of sintered samples with aspect ratio l/h >>5 is examined. The structure and properties of the composites consolidated by microwave and conventional (resistance) heating are compared. The use of microwaves for sintering of bulk parts from Si3N4–Y2O3–Al2O3 and TiN–AlN nanocomposites with a great l/h ratio revealed a number of issues in producing homogenous nanoceramics.

Similar content being viewed by others

References

D. E. Clark, D. C. Folz, C. Folgar, et al., Microwave Solutions for Ceramic Engineers, American Ceramic Society, Westerville, Ohio (2005), p. 494.

Microwave Processing of Materials, Committee on Microwave Processing of Materials: An Emerging Industrial Technology, Commission on Engineering and Technical Systems, National Academies Press, Washington D.C. (1994), p. 150.

S. A. Freeman, D. E. Clark, et al., Microwaves: Theory and Applications in Materials Processing II, American Ceramic Society, Westerville, Ohio (1993), p. 213.

D. Agrawal, “Latest global developments in microwave materials processing,” Mat. Res. Innovations, No. 14, 3–8 (2010).

S. Chockalingam and V. R. W. Amarakoon, “2.45 GHz microwave sintered Si3N4–ZrO2 composites,” J. Ceram. Soc. Jap., No. 6, 700–705 (2008).

O. I. Getman, V. V. Holoptsev, V. V. Panichkina, et al., “Mechanical properties of microwave sintered Si3N4-based ceramics,” Sci. Sintering, No. 34, 223–229 (2002).

Terry N. Tiegs, James O. Kiggans, H. T. Lin, and A. Craig Willkens, “Comparison of properties of sintered and sintered reaction-bonded silicon nitride fabricated by microwave and conventional heating,” MRS Proceedings, 347, 501–509 (1994).

O. B. Zgalat-Lozynskyy, A. V. Ragulya, and M. Herrmann, “Nonisothermal sintering of titanium nitride nanopowders,” Funct. Mater., 8, No. 1, 173–178 (2001).

Acknowledgments

The author is grateful to M. Herrmann and K. Sempf (IKTS, Dresden) for assistance in microstructural analysis and X-ray diffraction of sintered samples, to V. G. Kolesnichenko and L. V. Solyanik (IPMS) for assistance in the experiment, and to A. V. Ragulya (IMPS) for scientific discussion of experimental results.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 54, Nos. 1–2 (501), pp. 74–82, 2015.

Rights and permissions

About this article

Cite this article

Zgalat-Lozinskii, O.B. Structure of Si3N4–Y2O3–Al2O3 and TiN–AlN Composites Consolidated in Microwaves (2.45 GHz). Powder Metall Met Ceram 54, 60–66 (2015). https://doi.org/10.1007/s11106-015-9680-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9680-0