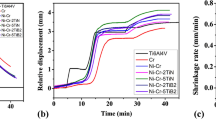

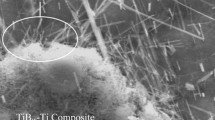

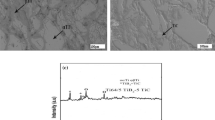

In this work, the mechanical properties such as elastic moduli, shear moduli, and hardness of titanium–titanium boride composites with 20% and 40% of titanium boride reinforcements were estimated by ultrasonic and nanoindentation techniques. The estimated values obtained from the both measuring techniques are compared. The composites were processed by three powder metallurgical techniques such as spark plasma sintering, hot isostatic pressing, and vacuum sintering. The composites processed through spark plasma sintering and hot isostatic pressing showed better mechanical properties compared to the vacuum sintered composites. The effects of titanium boride reinforcements and their morphological influences on the mechanical properties are also described.

Similar content being viewed by others

References

P. Chandrasekar, V. Balusamy, K. S. Ravi Chandran, and Harish Kumar, “Laser surface hardening of titanium–titanium boride (Ti–TiB) metal matrix composites,” Scripta Mater., 56, 641–644 (2007).

C. Guo, J. Zhou, J. Zhao, et al., “Microstructure and friction and wear behavior of laser boronizing composite coatings on titanium substrate,” Appl. Surf. Sci., 257, 4398–4405 (2011).

H. Dong and T. Bell, “Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment,” Wear, 238, 131–137 (2000).

C. Lee, A. Sanders, N. Tikekar, and K. S. Ravichandran, “Tribology of titanium boride –coated titanium balls against alumina ceramic: wear, friction, and micromechanisms,” Wear, 265, 375–386 (2008).

K. Morsi, V. V. Patel, S. Naraghi, and J. E. Garay, “Processing of titanium–titanium boride dual matrix composites,” J. Mater. Process. Technol., 196, 236–242 (2008).

Zh. Zhang, X. B. Shen, S. Wen, et al., “In situ reaction synthesis of Ti–TiB composites containing high volume fraction of TiB by spark plasma sintering process,” J. Alloys Compd., 503, 145–150 (2010).

Liu Yanbin, Liu Yong, T. Huiping, W. Bin, and Liu Bin. “Fabrication and mechanical properties of in situ TiC/Ti metal matrix composites,” J. Alloys Compd., 509, 3592–3601 (2011).

M. G. Kim, S. Y. Sung, and Y. J. Kim, “Synthesis of in-situ titanium carbide particle reinforced titanium composites,” Mater. Sci. Forum, 475–479, 963–966 (2005).

K. E. Geng, W. J. Lu, and D. Zhang, “In situ synthesized (TiB +Y2O3) / Ti composites,” J. Mater. Sci. Lett., 22, 877–79 (2003).

B. V. Radhakrishnabhat, J. Subramanyam, and V. V. Bhanuprasad, “Preparation of Ti–TiB–TiC & Ti–TiB composites by in-situ reaction hot pressing,” Mater. Sci. Eng. A, 325, 126–130 (2002).

K. S. Ravi Chandran and K. B. Panda, “Discontinuously reinforced titanium with titanium boride whiskers on the horizon,” Adv. Mater. Processes, 160, 59–62 (2002).

K. Geng, W. Lu, Z. Yang, and D. Zhang, “In situ preparation of titanium matrix composites reinforced by TiB and Nd2O3,” Mater. Lett., 57, 4054–4057 (2003).

S. Gorsse, J. P. Chaminade, and Y. Le Petitcorps, “In situ preparation of titanium base composites reinforced by TiB single crystals using a powder metallurgy technique,” Composites A, 29, 1229–1234 (1998).

A. Pettersson, P. Magnusson, P. Lundberg, and M. Nygren, “Titanium–titanium diboride composites as part of a gradient armor material,” Int. J. Imp. Eng., 32, 387–399 (2005).

S. S. Sahay, K. S. Ravi Chandran, and R. Atri, “Evolution of microstructure and phases in situ processed Ti–TiB composites containing high volume fractions of TiB whiskers,” J. Mater. Res., 14, 4214–4223 (1999).

S. Ranganath, M. Vijaykumar, and Subramanyam, “Combustion-assisted synthesis of Ti–TiB–TiC composite via the casting route,” Mater. Sci. Eng. A, 149, 253–257 (1992).

H. T. Tsang, C. G. Chao, and C. Y. Ma, “In situ fracture observation of a TiC /Ti MMC produced by combustion synthesis,” Scripta Mater., 35, 1007–1012 (1996).

J. Dutta Majumdar and L. Li, “Development of titanium boride (TiB) dispersed titanium (Ti) matrix composite by direct laser cladding,” Mater. Lett., 64, 1010–1012 (2010).

K. B. Panda and K. S. Ravichandran, “Synthesis of titanium–titanium boride (Ti–TiB) composites with a beta-titanium matrix: the nature of TiB formation and composite properties,” Metall. Mater. Trans. A, 34A, 1371–1385 (2003).

W. Min-Min, L. Wei-jie, Q. Ji-ning, et al., “The effect of reinforcements on superplasticity of in situ synthesized (TiB + TiC)/Ti matrix composite,” Scripta Mater., 54, 1955–1959 (2006).

R. R. Atri, K. S. Ravichandran, and S. K. Jha, “Elastic properties of in-situ processed Ti–TiB composites measured by impulse excitation of vibration,” Mater. Sci. Eng. A, 271, 150–159 (1999).

S. Gorsse, Y. L. Petitcorps, S. Matar, and F. Rebillat, “Investigation of the Young’s modulus of TiB needles in situ produced in titanium matrix composite,” Mater. Sci. Eng. A, 340, 80–87 (2003).

H. Feng, Y. Zhou, D. Jia, and Q. Meng, “Microstructure and mechanical properties of in situ TiB reinforced titanium matrix composites based on Ti–FeMo–B prepared by spark plasma sintering,” Compos. Sci. Technol., 64, 2495–2500 (2004).

X. Shen, Z. Zhang, S. Wei, et al., “Microstructure and mechanical properties of the in situ TiB –Ti metalmatrix composites synthesized by spark plasma sintering process,” J. Alloys Compd., 509, 7692–7696 (2011).

L. H. Lia, H. E. Kim, and E. S. Kang, “Sintering and mechanical properties of Titanium diboride with aluminum nitride as a sintering aid,” J. Eur. Ceram. Soc., 22, 973–977 (2002).

K. B. Panda and K. S. Ravichandran, “Titanium–titanium boride (TiB) functionally graded materials through reaction sintering: synthesis, microstructure and properties,” Metall. Mater. Trans. A, 34A, 1993–2003 (2003).

G. Kartal, S. Timur, M. Urgen, and A. Erdemir, “Electrochemical boriding of titanium for improved mechanical properties,” Surf. Coat. Technol., 204, 3935–3939 (2010).

S. Gorsse and D. B. Miracle, “Mechanical properties of Ti–6Al–4V/TiB composites with randomly oriented and aligned TiB reinforcements,” Acta Mater., 51, 2427–2442 (2003).

H. Feng, Y. Zhou, D. Jia, and Q. Meng, “Rapid synthesis of Ti alloy with B addition by spark plasma sintering,” Mater. Sci. Eng. A, 390, 344–349 (2005).

F. C. Wang, Zh. Zhang, J. Luo, et al.,, “A novel rapid route for in situ synthesizing TiB–TiB2 composites,” Compos. Sci. Technol., 69, 2682–2687 (2009).

P. Majumdar, S. B. Singh, and M. Chakraborty, “Elastic modulus of biomedical titanium alloys by nanoindentation and ultrasonic techniques—A comparative study,” Mater. Sci. Eng. A, 489, 419–425 (2008).

M. Doghmane, F. Hadjoub, A. Doghmane, and Z. Hadjoub, “Approaches for evaluating Young’s and shear moduli in terms of a single SAW velocity via the SAM technique,” Mater. Lett., 61, 813–816 (2007).

B. Raj, V. Moorthy, T. Jayakumar, and K. B. S. Rao, “Assessment of microstructures and mechanical behavior of metallic materials through nondestructive characterization,” Int. Mater. Rev., 48, 273–325 (2003).

W. C. Oliver and G. M. Pharr, “Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology,” J. Mater. Res., 19, No. 1, 3–20 (2004).

A. C. Fischer-Cripps, “Critical review of analysis and interpretation of nanoindentation test data,” Surf. Coat. Technol., 200, 4153–4165 (2006).

M. Selvakumar, P. Chandrasekar, P. Chandramohan, and M. Mohanraj, “Characterization of titanium–titanium boride composited processed by powder metallurgical techniques,” Mater. Charact., 73, 43–51 (2012).

K. E. Spear, P. McDowell, and F. McMahon, “Experimental evidence for the existence of the Ti3B4 phase,” J. Am. Ceram. Soc., 69, C4–C5 (1986).

N. Gupta, S. Ramesh Kumar, B. Ravisankar, and S. Kumaran, “Consolidation of Al–2024 powder by conventional P/M route and ECAP—A Comparative study,” World Academy of Science, Engineering and Technology, 61, 1067–1070 (2012).

R. Banerjee, S. Nag, and H. L. Fraser, “A novel combinatorial approach to the development of beta titanium alloys for orthopedic implants,” Mater. Sci. Eng. A, C25, 282–289 (2005).

Y. L. Hao, M. Ninomi, D. Kuroda, et al., “Young’s modulus and mechanical properties of Ti–29Nb–13Ta–4.6Zr in relation to α martensite,” Metall. Mater. Trans. A, 33, 3137–3144 (2002).

Acknowledgement

The authors acknowledge the All India Council for Technical Education (AICTE), New Delhi, for providing grant to carry out this work at Dr. Mahalingam College of Engineering and Technology, Pollachi, India. They also acknowledge Dr. P. Chandramohan, Professional Educational Trust Group of Institutions, Coimbatore, Dr. G. Apparao, DMRL, Hyderabad, Dr. Anish Kumar, IGCAR, Kalpakkam, Mr. M. Govindaraj, NFTDC, Hyderabad, Ms. Kalavathy, IGCAR–Kalpakkam, Mr. Dibyendu Chackravarthy, ARCI, Hyderabad and Mr. M. Thirumoorthy, ASL, Hyderabad for their support in processing the composites.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 53, No. 9–10 (499), pp. 81–91, 2014.

Rights and permissions

About this article

Cite this article

Selvakumar, M., Chandrasekar, P., Ravisankar, B. et al. Mechanical Properties of Titanium–Titanium Boride Composites Through Nanoindentation and Ultrasonic Techniques — An Evaluation Perspective. Powder Metall Met Ceram 53, 557–565 (2015). https://doi.org/10.1007/s11106-015-9650-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9650-6