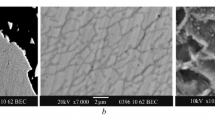

Differential thermal analysis and X-ray diffraction are used to study phase transitions in the Sm2Co17–xFex–H2 system (x =3.9 and 5.95) during conventional and solid HDDR at hydrogen pressure 0.57–4.0 MPa and temperature up to 950°C. The ferromagnetic phase with Th2Zn17 structure disproportionates into SmH2±x, cobalt, and intermetallic FeCo after one-hour interaction with hydrogen at 1.1 and 0.6 MPa and 700°C with x =3.9 and 5.95. Recombination in vacuum at 770–950°C leads to a two-phase alloy consisting of the Th2Zn17-type phase and intermetallic FeCo.

Similar content being viewed by others

References

K. J. Strnat and R. M. W. Strnat, “Rare earth–cobalt permanent magnets,” J. Magn. Magn. Mater., 100, 38–56 (1991).

R. Manaf, R. A. Buckley, and H. A. Davis, “New nanocrystalline high-remanence Nd–Fe–B alloys by rapid solidification,” J. Magn. Magn. Mater., 128, 302–306 (1993).

L. Withanawasam, G. C. Hadjipanayis, and R. F. Krause, “Enhanced remanence in isotropic Fe-rich melt-spun Nd–Fe–B ribbons,” J. Appl. Phys., 75, 6646–6648 (1994).

J. Ding, P. G. McCormick, and R. Street, “Remanence enhancement in mechanically alloyed isotropic Sm7Fe93-nitride,” J. Magn. Magn. Mater., 124, 1–4 (1993).

O. Donnell, C. Kuhrt, and J. M. D. Coey, “Influence of nitrogen content on coercivity in remanence-enhanced mechanically alloyed Sm–Fe–N,” J. Appl. Phys., 76, 7068–7070 (1994).

D. Lee, S. Bauser, A. Higgins, et al., “Bulk anisotropic composite rare earth magnets,” J. Appl. Phys., 99, 08B516-1–108B516-3 (2006).

G. C. Hadjipanayis and A. M. Gabay, “Overview of the high-temperature 2:17 magnets,” in: Proc. 18th Int. Workshop on High Performance Magnets and Their Applications HPMA’04, Annecy, France (2004).

G. C. Hadjipanayis, J. Liu, A. M. Gabay, and M. Marinesku, “Current status of rare-earth permanent magnet research in USA,” in: Proc. 19th Int. Workshop on High Performance Magnets and Their Applications, Beijing, China (2006), pp. 12–22.

A. M. Gabay, W. F. Li, and G. C. Hadjipanayis, “Effect of hot deformation on texture and magnetic properties of Sm–Co and Pr–Co alloy,” J. Magn. Magn. Mater., 323, 2470–2473 (2011).

N. Poudyal and J. P. Liu, “Advances in nanostructured permanent magnets research,” J. Phys. D: Appl. Phys., 46, 1–23 (2013).

N. Cannesan and I. R. Harris, “Aspects of NdFeB HDDR powders: fundamentals and processing,” in: G. C. Hadjipanayis (ed.), Bonded Magnets (NATO Science), series II “Mathematics, Physics, and Chemistry,” Kluwer Academic Publishers (2002), Vol. 118, pp. 13–36.

O. Gutfleisch, M. Matzinger, J. Fidler, and I. R. Harris, “Characterization of solid-HDDR processed Nd16Fe76B8 alloys by means of electron microscopy,” J. Magn. Magn. Mater., 47, 320–330 (1995).

I. I. Bulik, V. V. Panasyuk, and A. M. Trostyanchin, Method of Forming Anisotropic Fine-Grained Sm–Co Alloy Powders by Hydrogen–Vacuum Thermal Treatment [in Ukrainian], Ukrainian Patent No. 96810, H 01 F 1/053, H 01 F 1/055, B 82 B 3/00, Bulletin No. 23, publ. December 12 (2011), p. 7.

I. I. Bulik, V. V. Panasyuk, and A. M. Trostyanchin, Method of Forming Anisotropic Fine-Grained Sm–Co Alloy Powders by Grinding in Hydrogen [in Ukrainian], Ukrainian Patent No. 96811, H 01 F 1/053, H 01 F 1/055, B 82 B 3/00, Bulletin No. 12, publ. December 12 (2011), p. 11.

I. I. Bulik and V. V. Panasyuk, “Hydrogen as a process environment for forming nanostructure in ferromagnetic Sm–Co alloys,” Fiz. Khim. Mekh. Mater., 48, No. 1, 9–18 (2012).

I. I. Bulik, V. V. Burkhovetskii, V. Yu. Tarenkov, and P. Ya. Lyutyi, “Change in Sm2Co17 microstructure during disproportionation in hydrogen,” Metallofiz. Noveish. Tekhnol., 35, No. 9, 1283–1294 (2013).

I. I. Bulik, R. V. Denis, V. V. Panasyuk, et al., “HDDR process and hydrogen sorption properties of didymium–aluminum–iron–boron (Dd12.3Al1.2Fe79.4B6) alloy,” Fiz. Khim. Mekh. Mater., 37, No. 4, 15–20 (2001).

I. I. Bulik, Yu. B. Basaraba, A. M. Trostyanchin, and V. M. Davydov, “Disproportionation in hydrogen and recombination of zirconium–chromium Laves phases,” Fiz. Khim. Mekh. Mater., 41, No. 3, 101–108 (2005).

Electronic Registry: www.ccp14.ac.uk .

Electronic Registry: www.ill.eu/sites/fullprof .

N. C. Christodoulou and T. Takeshita, “Sm2Co17-nitride-based permanent magnets produced by the hydrogenation–decomposition–desorption–recombination (HDDR) process,” J. Alloys Compd., 196, 155–159 (1993).

M. V. Satyanarayana, W. E. Wallace, and R. S. Craig, “Effects of substitution of chromium and nickel on the magnetic properties of Er2Co17 and Sm2Co17,” J. Appl. Phys., 50, 2324–2326 (1979).

F. Meyer-Liautaud, C. H. Allibert, and R. Castanet, “Enthalpies of formation of Sm–Co alloys in the composition range 10–22 at.% Sm,” J. Less.-Common Met., 127, 243–250 (1987).

H. Y. Chen, S. G. Sankar, and W. E. Wallace, “Spin reorientation in substituted Nd2Co17 compounds,” J. Appl. Phys., 63, 3969–3971 (1988).

A. Deryagin, A. Ulyanov, N. Kudrevatykh, et al., “Magnetic characteristics and lattice constants of some pseudobinary intermetallic compounds of the type R2T17,” Phys. St. Sol. A, 23, K15–K18 (1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 53, No. 5–6 (497), pp. 115–126, 2014.

Rights and permissions

About this article

Cite this article

Bulyk, I.I., Pilat, M.V. & Lyutyy, P.Y. Hydrogenation, Disproportionation, Desorption, and Recombination in the Sm2Co17–x Fe x –H2 System (x =3.9 and 5.95). X-Ray Diffraction. Powder Metall Met Ceram 53, 343–352 (2014). https://doi.org/10.1007/s11106-014-9622-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-014-9622-2