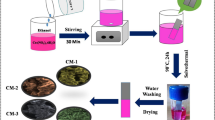

In this research, open cell Ni–SiC and Cu–SiC composite foams are produced by electrolytic codeposition on the polyurethane foam substrates using conventional metal plating electrolytes with suspended SiC nanoparticles. The method ensures the production of MMC open-cell foams; content of SiC inclusions in the metal matrix of up to 10 wt.% can be controlled by the SiC powder concentration in the electrolytes. Effects of the foam pore size (surface area) and the electrolyte composition on the content of SiC inclusions and the density gradient across the foam are studied.

Similar content being viewed by others

References

M. F. Ashby, “The properties of foams and lattices,” Philos. Trans. R. Soc. Ser. A, 364, 15–30 (2006).

J. Banhart, “Manufacture, characterization and application of cellular metals and metal foams,” Prog. Mater. Sci., 46, 559–632 (2001).

L. Giani, G. Groppi, and E. Tronconi, “Mass-transfer characterization of metallic foams as supports for structured catalysts,” Ind. Eng. Chem. Res., 44, 4993–5002 (2005).

T. J. Lu, A. Hess, and M. F. Ashby, “Sound absorption in metallic foams,” J. Appl. Phys., 85, 7528–7539 (1999).

A. N. Leonov, O. L. Smorygo, and V. K. Sheleg, “Monolithic catalyst supports with foam structure,” React. Kinet. Catal. Lett., 60, 259–267 (1997).

A. Leonov and A. Romashko, “Quality control of foam metals produced electrochemically,” in: J. Banhart and N. Fleck (eds.), Cellular Metals: Manufacture, Properties, Applications, Verlag MIT Publishing, Berlin (2003), pp. 158–161.

O. Smorygo et al., “Nickel foams with oxidation-resistant coatings formed by combustion synthesis,” Scripta Mater., 58, 910–913 (2008).

O. Smorygo et al., “Structured catalyst supports and catalysts for the methane indirect internal steam reforming in the intermediate temperature SOFC,” Int. J. Hydrogen Energy, 4, 9505–9514 (2009).

A. Gomes et al., “Electrodeposition of metal matrix nanocomposites: improvement of the chemical characterization techniques,” in: B. Reddy (ed.), Advances in Nanocomposites—Synthesis, Characterization and Industrial Applications, InTech, Rijeka (2011), pp. 503–526.

H. K. Lee, H. Y. Lee, and J. M. Jeon, “Codeposition of micro- and nanosized SiC particles in the nickel matrix composite coatings obtained by electroplating,” Surf. Coat. Technol., 201, 4711–4717 (2007).

J. Zhu et al., “Study on composite electroforming of Cu/SiCp composites,” Mater. Lett., 58, 1634–1637 (2004).

L. J. Brown and S. Sotiropoulos, “Electroplating and electroless plating of Ni through/onto porous a polymer in a flow cell,” J. Appl. Electrochem., 31, 1203–1212 (2001).

M. A. Shluger (ed.), Galvanic Coatings in Mechanical Engineering: Handbook [in Russian], Mashinostroenie, Moscow (1985).

M. Shalkauskas and A. Vashkjalis, Chemical Metallization of Plastics [in Russian], Chemistry Publishing, Leningrad (1985).

M. A. Belen’kijj and A. F. Ivanov, Handbook of Electrodeposition of Metallic Coatings [in Russian], Metallurgiya, Moscow (1985).

O. Smorygo et al., “An inverted spherical model of open-cell foam structure,” Acta Mater., 59, 2669–2678 (2011).

Acknowledgements

The authors acknowledge DRDO, India and Belarussian Foundation of Fundamental Research (integrated project of the National Academy of Sciences of Belarus and Siberian Branch of Russian Academy of Sciences T12CO-020) for the support of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 52, No. 9–10 (493), pp. 74–81, 2013.

Rights and permissions

About this article

Cite this article

Mikutski, V., Smorygo, O., Shchurevich, D. et al. Open-Cell Metal–SiC Composite Foams made by Electrolytic Codeposition on Polyurethane Substrates. Powder Metall Met Ceram 52, 545–550 (2014). https://doi.org/10.1007/s11106-014-9558-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-014-9558-6