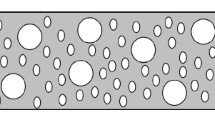

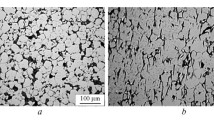

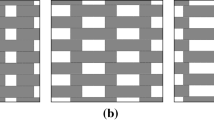

The behavior of porous materials with bimodal pore distribution under external loads and kinematic constraints is considered. Numerical methods of continuum mechanics of sintering are used. The effect of partial and complete constraining of the surface bounding the billets in sintering is studied. Corresponding distributions of small and large pores are determined. The sensitivity of the distributions to constraining/loading paths is established.

Similar content being viewed by others

References

A. V. Kuz’mov and M. B. Shtern, “Mechanics of sintering materials with bimodal pore distribution. I. Effective characteristics of biporous materials and equations of the evolution of pores of different radii,” Powder Metall. Met. Ceram., 44, No. 9–10, 429–434 (2005).

E. A. Olevsky, “Theory of sintering: From discrete to continuum,” Mat. Sci. Eng., R23, 41–100 (1998).

V. V. Skorokhod, E. A. Olevskii, and M. B. Shtern, “Continuum theory of sintering. III. Effect of inhomogeneous distribution of properties in compacts and of pressing conditions on the kinetics of sintering,” Powder Metall. Met. Ceram., 32, No. 3, 208–213 (1993).

V. V. Skorokhod, M. B. Shtern, A. V. Kuz’mov, et al., “Mechanics of sintering materials with bimodal pore distribution. III. Kinetics of sintering combined with various forms of loading and adhesion conditions,” Powder Metall. Met. Ceram., 45, No. 5–6, 221–225 (2006).

R. M. German and M. Bulger, “A model for densification by sintering of bimodal particle size distribution,” Int. J. Powder Met., 28, No. 3, 301–311 (1992).

Ya. E. Geguzin, Physics of Sintering [in Russian], 2nd Edition, Nauka, Moscow (1984).

G. W. Scherer, “Coarsening in viscous matrix,” J. Am. Ceram. Soc., 81, No 1, 49–54 (1998).

V. V. Skorokhod, Rheology Basis of Sintering Theory [in Russian], Naukova Dumka, Kiev (1972), p. 151.

G. W. Scherer, “Sintering of low density glasses. I. Theory,” J. Am. Ceram. Soc., 60, No. 5, 236 (1977).

R. K. Bordia and G. W. Scherer, “On constrained sintering. 1. Constitutive model for a sintering body,” Acta Met., 36, No 9, 2393–2397 (1988).

G. W. Scherer, “Viscous sintering of a bimodal pore–size distribution,” J. Am. Ceram. Soc., 67, No. 11, 709–715 (1984).

G. W. Scherer, “Viscous sintering with a pore–size distribution and rigid inclusions,” J. Am. Ceram. Soc., 71, No. 10, 447 (1988).

E. Olevsky and R. Rein, “Kinetics of sintering for powder systems with bimodal pore distribution,” Int. J. High Temp. High Press., 27–28, 81–90 (1995).

E. Levanen and T. Mantyla, “Effect of sintering temperature on functional properties of alumina membranes,” J. Europ. Ceram. Soc., 22, 613–623 (2002).

V. V. Skorokhod and M. B. Shtern, “Mechanics of sintering materials with bimodal pore distribution. II. Mean-square strain rate for the solid phase of a biporous body and instability of the monomodal pore structure during constrained sintering,” Powder Metall. Met. Ceram., 45, No. 1–2, 28–34 (2006).

E. Olevsky and A. Molinary, “Instability of sintering of porous bodies,” Int. J. Plasticity, 16, No. 1, 1–37 (2000).

A. G. Evans and C. H. Hsueh, “Behavior of large pores during sintering and hot isostatic pressing,” J. Am. Ceram. Soc., 69, No. 6, 444 (1986).

C. H. Hsueh, A. G. Evans, and R. M. McMeeking, “Influence of multiple heterogeneities on sintering rates,” J. Am. Ceram. Soc., 69, No. 4, C64–C66 (1986).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 49, No. 1–2 (471), pp. 23–31, 2010.

This section represents articles based on papers delivered at the International Conference on Sintering (ICS IX, Kiev, September 7–11, 2009).

Rights and permissions

About this article

Cite this article

Shtern, M.B., Kuz’mov, A.V., Skorokhod, V.V. et al. Sintering stability of biporous materials under kinematic constraints. Powder Metall Met Ceram 49, 17–23 (2010). https://doi.org/10.1007/s11106-010-9196-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-010-9196-6