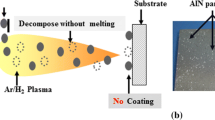

The paper examines and compares the properties of Al2O3 coatings sprayed using two methods: arc plasma spraying (APS) of micron powders (average particle size is 45 μm) and suspension plasma spraying (SPS) (average particle size is 2.9 μm). A system for feeding suspension into plasma spray is developed and fabricated. It is established that SPS coatings contain finer structural components than APS. This improves their mechanical characteristics such as microhardness and indentation fracture toughness.

Similar content being viewed by others

References

V. E. Oliker, V. L. Sirovatka, I. I. Timofeeva, et al., “Formation of detonation coatings based on titanium aluminide alloys and aluminum titanate ceramic sprayed from mechanically alloyed powders Ti–Al,” Surf. Coat. Technol., 200, 3573–3581 (2006).

P. R. Strutt, B. H. Kear, and R. Boland, Nanostructured Feeds for Thermal Spray Systems, Method of Manufacture and Coatings Formed Therefrom, Patent 6,025,034 U.S., Publ. 15.02.2000.

L. L. Shaw, D. Goberman, R. Ren, et al., “The dependency of microstructure and properties of nanostructured coatings on plasma spray conditions,” Surf. Coat. Technol., 130, 1–8 (2000).

Y. Wang, S. Jiang, M. Wang, et al., “Abrasive wear characteristics of plasma sprayed nanostructured alumina/titania coatings,” Wear, 237, 176–185 (2000).

X. Lin, Y. Zeng, S. W. Lee, and C. Ding, “Characterization of alumina–3 wt.% titania coating prepared by plasma spraying of nanostructured powders,” J. Europ. Ceram. Soc., 24, 627–634 (2004).

R. S. Lima and B. R. Marple, “Enhanced ductility in thermally sprayed titania coating synthesized using a nanostructured feedstock,” Mat. Sci. Eng. A, 35, No. 12, 269–280 (2005).

E. H. Jordan, L. Xie, X. Ma, et al., “Superior thermal barrier coatings using solution precursor plasma spray,” J. Therm. Spray., 13, 57–65 (2004).

G. M. Chow, L. K. Kutihara, T. D. Xiao, et al., Nanosize Particle Coatings Made by Thermal Spraying Solution Precursor Feedstoks, Patent 6,447,848 U.S., Publ. 9.10.02.

M. Gell, L. Xie, X. Ma. et al., “Highly durable thermal barrier coatings made by the solution precursor plasma spray process,” Surf. Coat. Technol., 177, 97–102 (2004).

P. Fauchais, R. Etchart-Salas, C. Delbos, et al., “Suspension and solution plasma spraying of finely structured layers: potential application to SOFCs,” J. Physics D: Applied Physics, 40, 2394–2406 (2007).

G. G. Maksimovich, V. F. Shatinskii, and V. I. Kopylov, Physical and Chemical Processes in Plasma Spraying and Failure of Coated Materials [in Russian], Naukova Dumka, Kiev (1983), p. 320.

E. V. Panchenko, Yu. A. Skakov, B. I. Krimer, et al., Metallography Laboratory [in Russian], Metallurgiya, Moscow (1965), p. 439.

A. Hasui, Spraying Techniques [Russian translation], Mashinostroenie, Moscow (1975), p. 236.

J. Friedel, Dislocations, Pergamon Press, New York (1967).

A. F. Evans and T. K. Wilshaw, “Quasi-static solid particle damage in brittle solids. Observations, analysis, and implications,” Acta Metal., 24, No. 10, 939–956 (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 48, No. 1–2 (465), pp. 148–155, 2009.

Rights and permissions

About this article

Cite this article

Oliker, V.E., Terent’ev, A.E., Shvedova, L.K. et al. Use of aqueous suspensions in plasma spraying of alumina coatings. Powder Metall Met Ceram 48, 115–120 (2009). https://doi.org/10.1007/s11106-009-9085-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-009-9085-z