Abstract

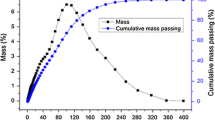

The use of an inertial cone mill to grind iron and boron carbide powder mixtures is examined. The dependence of the particle-size distribution in the mixture after grinding on the maximum particle size is analyzed. It is established that the content of coarse-grained fractions (larger than 100 µ m) substantially decreases as compared with the initial powder even after three grinding cycles. If the number of grinding cycles is increased to 20, the content of finer fractions (smaller than 63 µ m) is only 6 to 8% higher than in powders subjected to 3–12 grinding cycles in the inertial cone mill. Therefore, more than 3 or 6 cycles to produce Fe-B4C powder with the optimal content of the ≤100≤63 µ m fraction are unreasonable.

Similar content being viewed by others

References

Yu. S. Borisov, V. E. Oliker, E. A. Astakhov, et al., “Structure and properties of gas-thermal coatings of Fe-B-C and Fe-Ti-B-C alloys,” Powder Metall. Met. Ceram., 26, No. 4, 313–318 (1987).

M. D. Egorov, Yu. L. Sapozhnikov, R. M. Katsel’, Yu. V. Shokhnazarov, “Studying the structure and properties of boron-containing alloys,” in: Proc. 3rd Sci-.Techn. Conf. on Composite Coatings [in Russian], Zhitomir (1985), pp. 36–37.

I. M. Spiridonova, E. V. Sukhovaya, V. F. Butenko, et al., “Structure and properties of boron-bearing iron granules for composites,” Powder Metall. Met. Ceram., 32, No. 2, 129–141 (1993).

V. F. Tkachenko, Yu. I. Kogan, and V. A. Koval’chuk, “Sintered structural materials made from iron-boron carbide powder mixture,” in: Structural Materials [in Russian], Kiev (1978), pp. 30–34.

V. F. Tkachenko and Yu. I. Kogan, “Structural characteristics and mechanical properties of sintered Fe-B4C materials,” Powder Metall. Met. Ceram., 17, No. 5, 384–388 (1978).

V. I. Revnivtsev, V. L. Girshov, G. A. Finkel’shtein, et al., “Comminution of metal powders and swarf,” Powder Metall. Met. Ceram., 21, No. 4, 261–265 1982.

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 47, No. 3–4 (460), pp. 129–134, 2008.

Rights and permissions

About this article

Cite this article

Baglyuk, G.A., Pyatachuk, S.G., Dyadyun, V.M. et al. Grinding of Fe-B4C powder charge in an inertial cone mill. Powder Metall Met Ceram 47, 260–263 (2008). https://doi.org/10.1007/s11106-008-9013-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-008-9013-7