Abstract

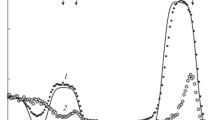

The anodic oxidation of MoSi2 ceramics in 3% NaCl solution is shown to be a multistage process. Auger electron spectroscopy established that only silica forms on the MoSi2 surface between 1.5 and 2.0 V, while molybdenum passes completely into solution. The growth kinetics of silica is studied using chronoamperometry under controlled potential conditions. The resulting kinetic curves show two stages. At the first stage, the reaction rate (current density) falls by one order for the first few minutes when SiO2 nanofilm begins to form. Then the diffusion-limited process, which fits parabolic kinetics, is established. On the whole, the model describing the electrochemical formation of oxide nanofilm on molybdenum disilicide agrees with the Mott-Cabrera theory, which was earlier proposed for high-temperature oxidation processes.

Similar content being viewed by others

References

K. Hansson, M. Halvarsson, J. E. Tang, et al., “Oxidation behavior of a MoSi2-based composite in different atmospheres in the low temperature range (400–550°C),” J. Europ. Ceram. Soc., 24, 3559–3573 (2004).

K. Hansson, J. E. Tang, M. Halvarsson, et al., “The beneficial effect of water vapour on the oxidation at 600 and 700°C of a MoSi2-based composite,” J. Europ. Ceram. Soc., 25, 1–11 (2005).

F. Zhang, L. Zhang, A. Shan, et al., “Oxidation of stoichiometric poly-and single-crystalline MoSi2 at 773 K,” Intermetallics, 14, 406–411 (2006).

G. Jang, R. Kieffer, and H. Kogler, “Korrosionsprüfungen an Siliziden der Übergangsmetalle,” Werkstoffe und Korrosion, 21, 699–703 (1970).

R. D. Armstrong and A. F. Douglas, “The anodic oxidation of the binary compounds of the transition elements in sulphuric acid,” J. Appl. Electrochem., 2, 143–149 (1972).

M. Herranen, A. D. Bauer, J.-O. Carlsson, et al., “Corrosion properties of thin molybdenum silicide films,” Surf. Coat. Tech., 96, 245–254 (1997).

A. D. Chirkin, V. A. Lavrenko, A. D. Panasyuk, et al., “Formation of oxide nanofilms over titanium, molybdenum, and tungsten disilicides in anodic polarization,” Dop. NAN Ukrainy, 12, 96–101 (2006).

Y. Q. Liu, G. Shao, and P. Tsakiropoulos, “On the oxidation behavior of MoSi2,” Intermetallics, 9, 125–136 (2001).

D. L. Cocke, R. Schennach, M. A. Hossain, et al., “The low-temperature thermal oxidation of copper, Cu3O2, and its influence on past and future studies,” Vacuum, 79, 71–83 (2005).

G. Tremiliosi-Filho, L. H. Dall’Antonia, and G. Jerkiewicz, “Growth of surface oxides on gold electrodes under well-defined potential, time and temperature conditions,” J. Electroanal. Chem., 578, 1–8 (2005).

G. C. Willis, G. B. Adams, and P. Van Rysselberghe, “Electrolytic formation of insulating oxide films on zirconium. II. Electrode kinetics at constant voltage,” Electroch. Acta., 9, 93–101 (1964).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 47, No. 1–2 (459), pp. 161–167, 2008.

Rights and permissions

About this article

Cite this article

Lavrenko, V.A., Chirkin, A.D., Talash, V.N. et al. Growth kinetics of SiO2 nanofilm on MoSi2 in anodic polarization. Powder Metall Met Ceram 47, 124–128 (2008). https://doi.org/10.1007/s11106-008-0017-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-008-0017-0